Specifications:

| Model |

3015GU |

| Working Area |

3000 × 1500 mm - 6000 × 1500 mm |

| Laser Power |

1.5kw – 6kw |

| Laser Source |

Raycus / Max / RECI / IPG |

| Laser Type |

Fiber |

| Cutting Thickness |

1–3 mm |

| Cutting Speed |

80 m/min |

| Positioning Accuracy |

±0.03 mm |

| Re-positioning Accuracy |

±0.02 mm |

| Laser Head |

BOCI / RAYTOOLS |

| Control System |

FSCUT |

| Motors & Drivers |

DELTA / Fuji / Yaskawa |

| Linear Guide |

HONGNIU |

Description:

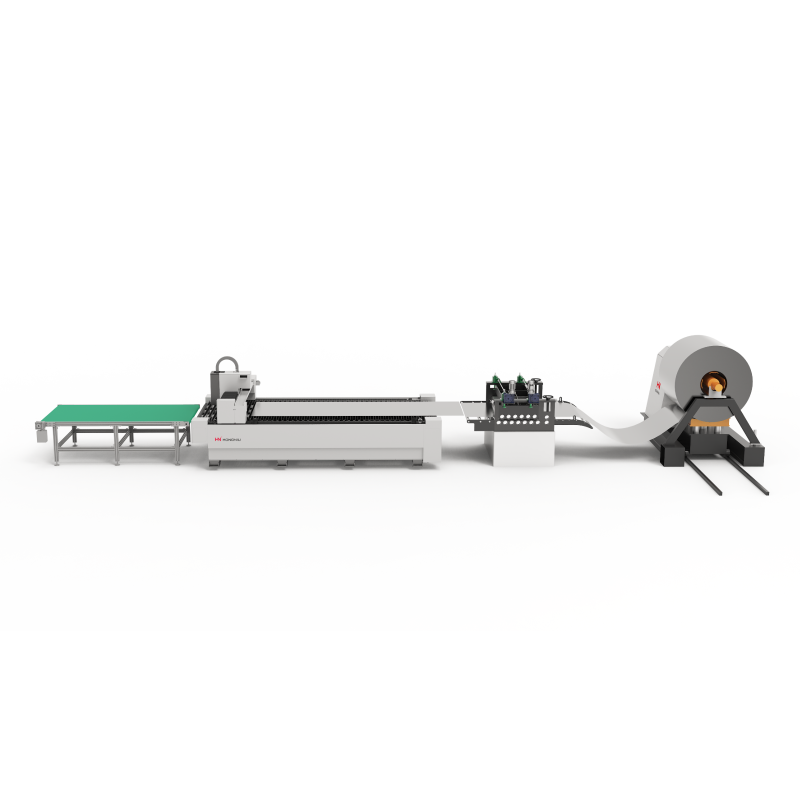

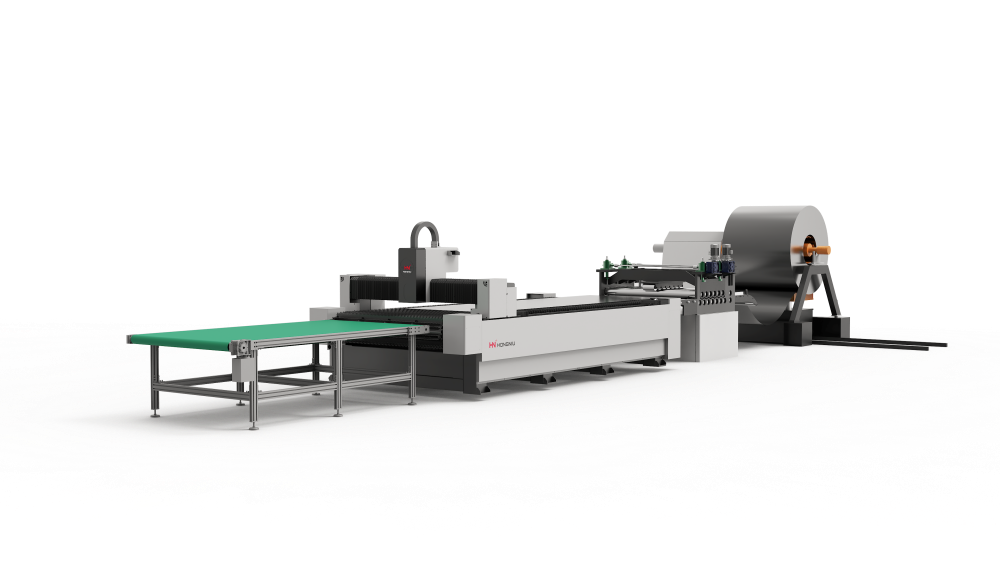

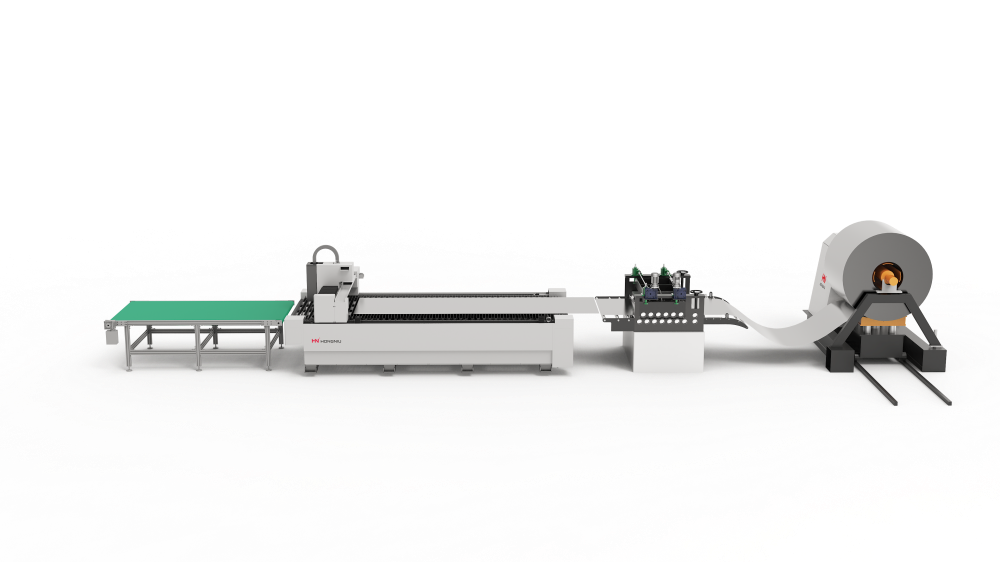

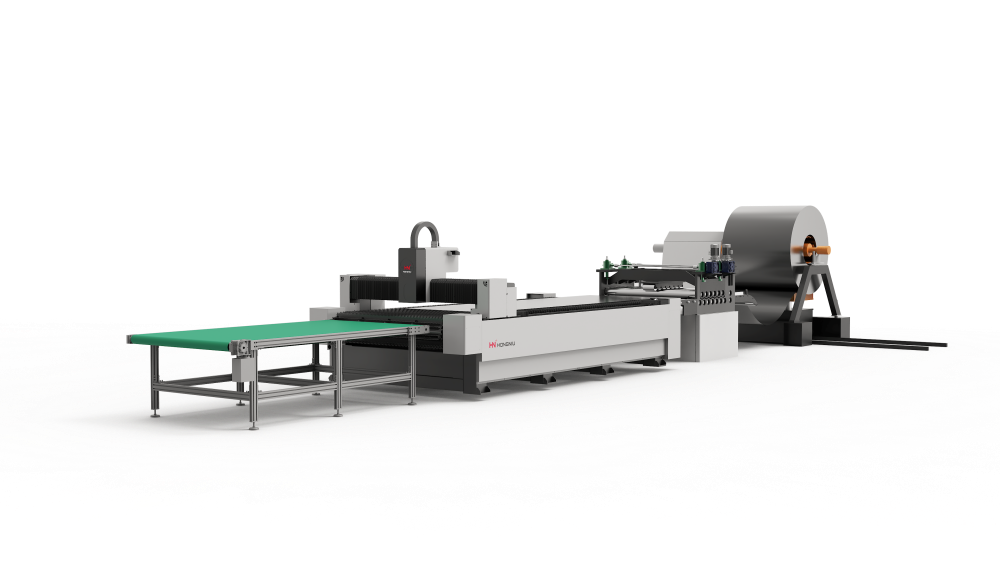

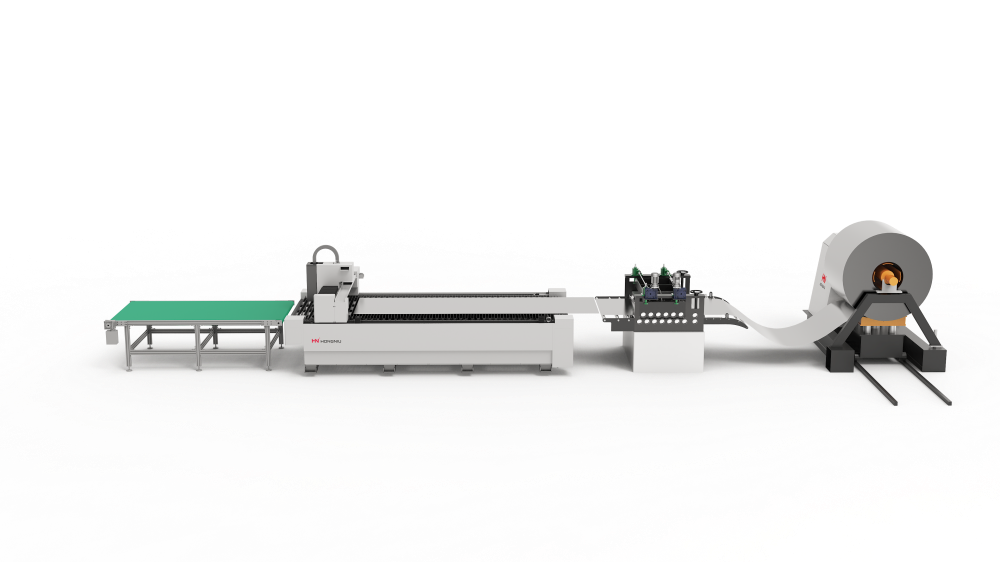

The GU Series Automatic Coil-Fed Fiber Laser Cutting Production Line is designed for high-speed, high-volume sheet metal processing using metal coils. By integrating automatic uncoiling, leveling, continuous feeding, laser cutting, and receiving, this system enables uninterrupted production and dramatically improves efficiency.

It is especially suitable for thin metal sheets (1–3 mm), providing consistent accuracy, excellent surface quality, and reduced material waste.

High-Quality Components for Reliable Performance

- Laser Source: Raycus / Max / RECI / IPG fiber lasers with stable output and long service life

- Laser Head: BOCI or RAYTOOLS with auto-focus, anti-collision protection, and intelligent monitoring

- Control System: FSCUT supports CAD/DXF, simulation preview, multi-file processing, and flying cutting

- Motors & Drivers: DELTA / Fuji / Yaskawa for high-speed and precise motion control

- Electrical Components: Schneider & Omron ensure stable and safe operation

- Cooling System: Industrial water chiller with over-temperature alarm

- Automatic Lubrication: Programmable lubrication system extends machine service life

Specifications and Performance

The GU series supports continuous coil-fed cutting with laser power up to 6kw, making it ideal for mass production of thin sheet metal parts. The gantry double-drive structure and heavy-duty honeycomb bed ensure long-term stability and precision during high-speed cutting operations.

Multiple beams can be processed simultaneously, and optional automatic receiving systems further enhance production efficiency.

Applications and Versatility

Applicable Materials:

-

Carbon Steel

-

Stainless Steel

-

Aluminum

-

Copper

-

Brass

- Galvanized Sheet

The system is optimized for coil material processing, ensuring uniform cutting quality across long production runs.

Applications:

- Automatic coil-fed sheet metal cutting

- Mass production of thin metal components

- Electrical cabinets and enclosures

- Home appliance panels

- Automotive sheet metal parts

- Advertising and decorative metal panels

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Fully Automatic Coil Processing: Uncoiling, leveling, cutting, and receiving in one line

- High Production Efficiency: Continuous feeding reduces downtime and labor costs

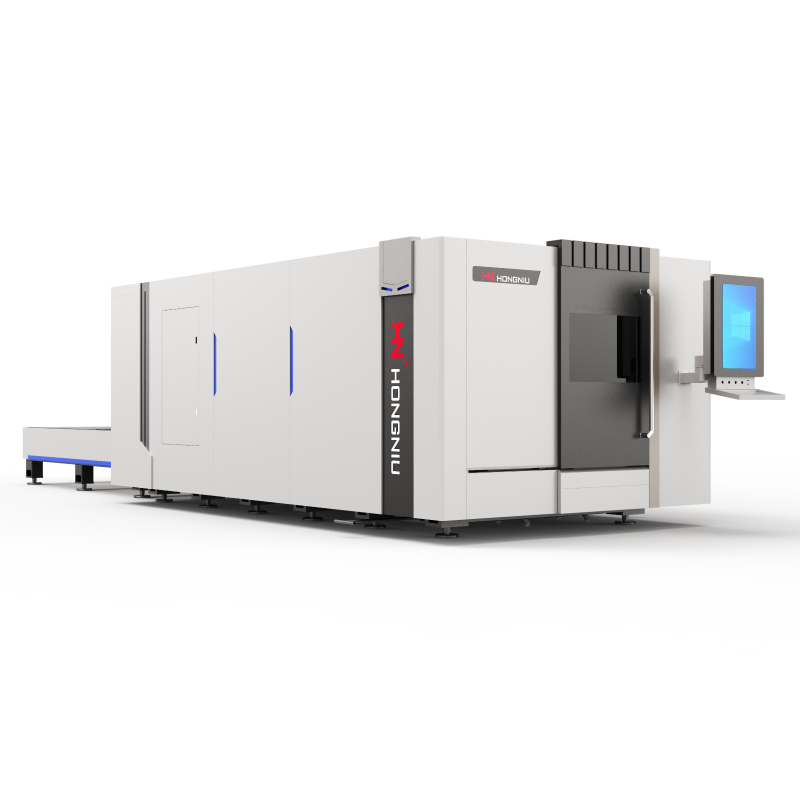

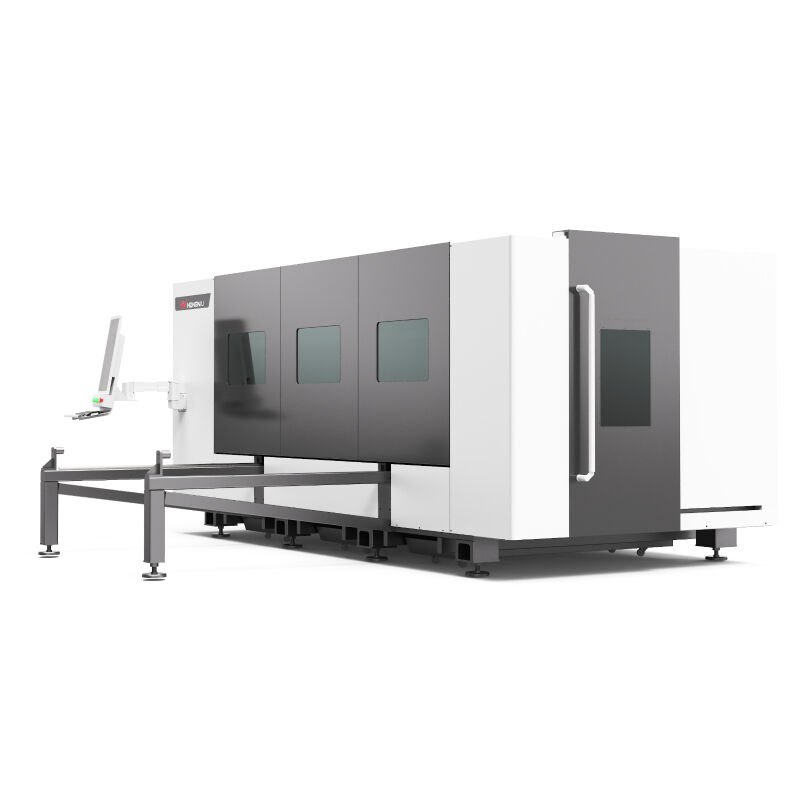

- Flexible Configuration: Open or fully enclosed structure optional

- Rolling Cutting Table: Smooth material movement and stable cutting

- High Precision: ±0.03 mm positioning accuracy

- Low Operating Cost: Optimized for thin sheet metal with minimal waste

- Premium Components: Raycus/IPG lasers, BOCI/RAYTOOLS heads, FSCUT control system

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Automatic Coil Fed Laser Cutting Line

- Coil Feeding Fiber Laser Cutting Machine

- Sheet Metal Coil Laser Cutting System

- High Speed Coil Laser Cutting Production Line

-

Industrial Fiber Laser Cutting Line