Core Specifications:

| Model |

3015LS |

| Working Area |

3000 × 1500 mm |

| Laser Power |

1.5KW – 30KW |

| Laser Source |

Raycus / Max / RECI / IPG |

| Laser Head |

BOCI / RAYTOOLS |

| Motor & Drivers |

DELTA / Fuji / Yaskawa |

| Control System |

FSCUT |

| Cutting Speed |

80 m/min |

| Positioning Accuracy |

±0.03 mm |

| Re-positioning Accuracy |

±0.02 mm |

| Cooling Method |

Water Cooling |

| Machine Size |

5600 × 2280 × 2300 mm |

| Gross Weight |

4000 kg |

Description:

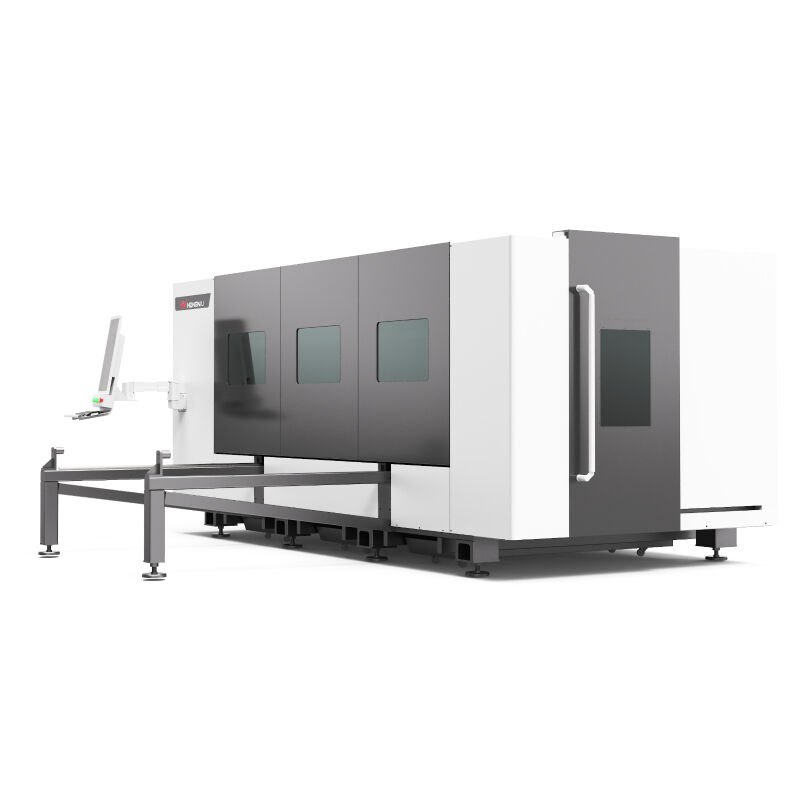

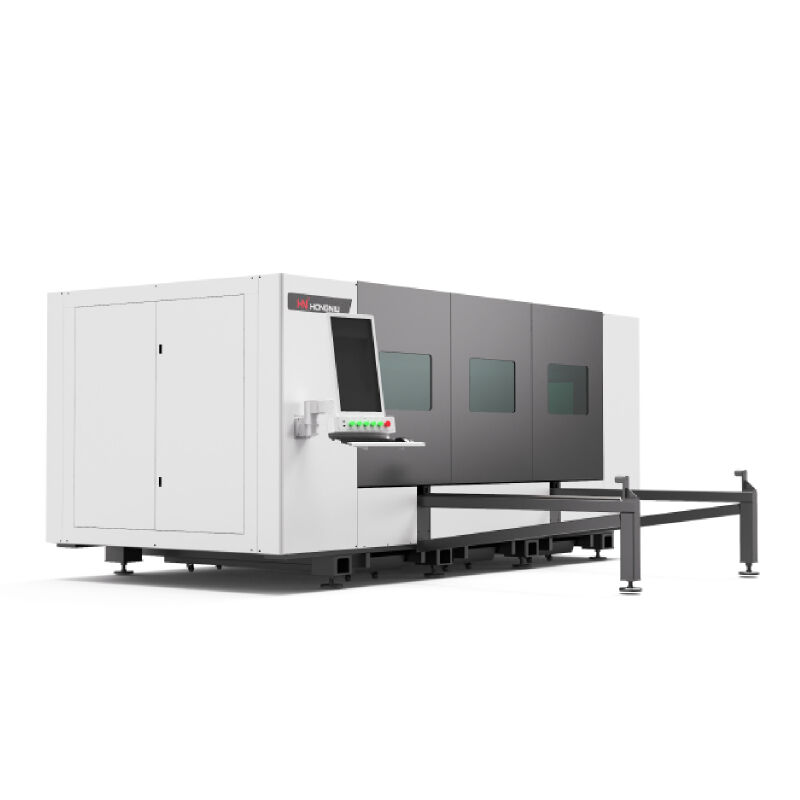

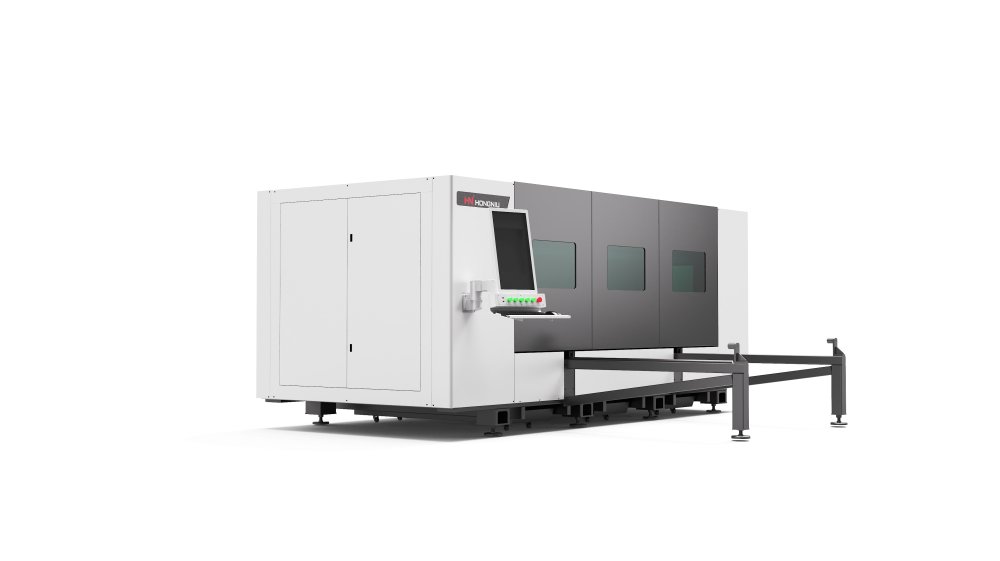

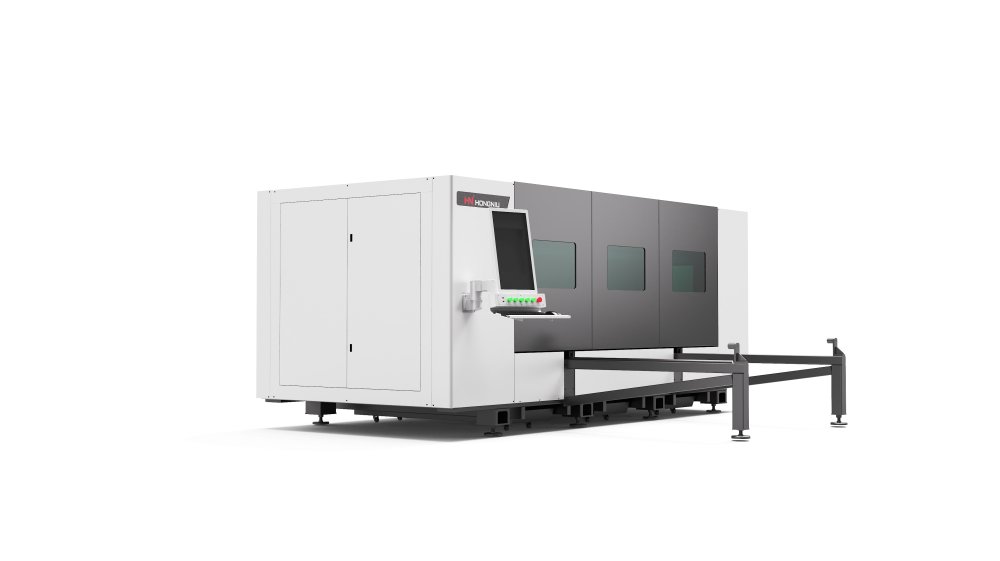

Single Platform Enclosed Fiber Laser Cutting Machine – Model 3015LS

The 3015LS is designed for industrial manufacturers seeking precision, safety, and efficiency in sheet metal processing. With its fully enclosed cabinet design and intelligent dust extraction system, it provides a clean, energy-efficient, and safe working environment while delivering high-quality cuts across various metal types.

Fully Enclosed, User-Friendly Design

The cabinet-mounted machine ensures quick setup and transport. Equipped with an electric workbench and a large-span lifting door, the 3015LS makes material loading and unloading effortless while allowing convenient access for operation and maintenance.

Advanced Dust & Smoke Management

A three-zone blow-and-suction dust removal system efficiently removes smoke and debris during cutting. This not only maintains a clean workshop environment but also prolongs the life of the laser optics and ensures consistent cutting quality.

Stable Structure & Precise Cutting

The honeycomb carbon bed, combined with gantry double-drive structure and high-strength beam, ensures rigidity, minimal vibration, and long-term accuracy. Its high-speed servo motors and advanced control system deliver smooth motion and precise cutting even on thick materials up to 50mm.

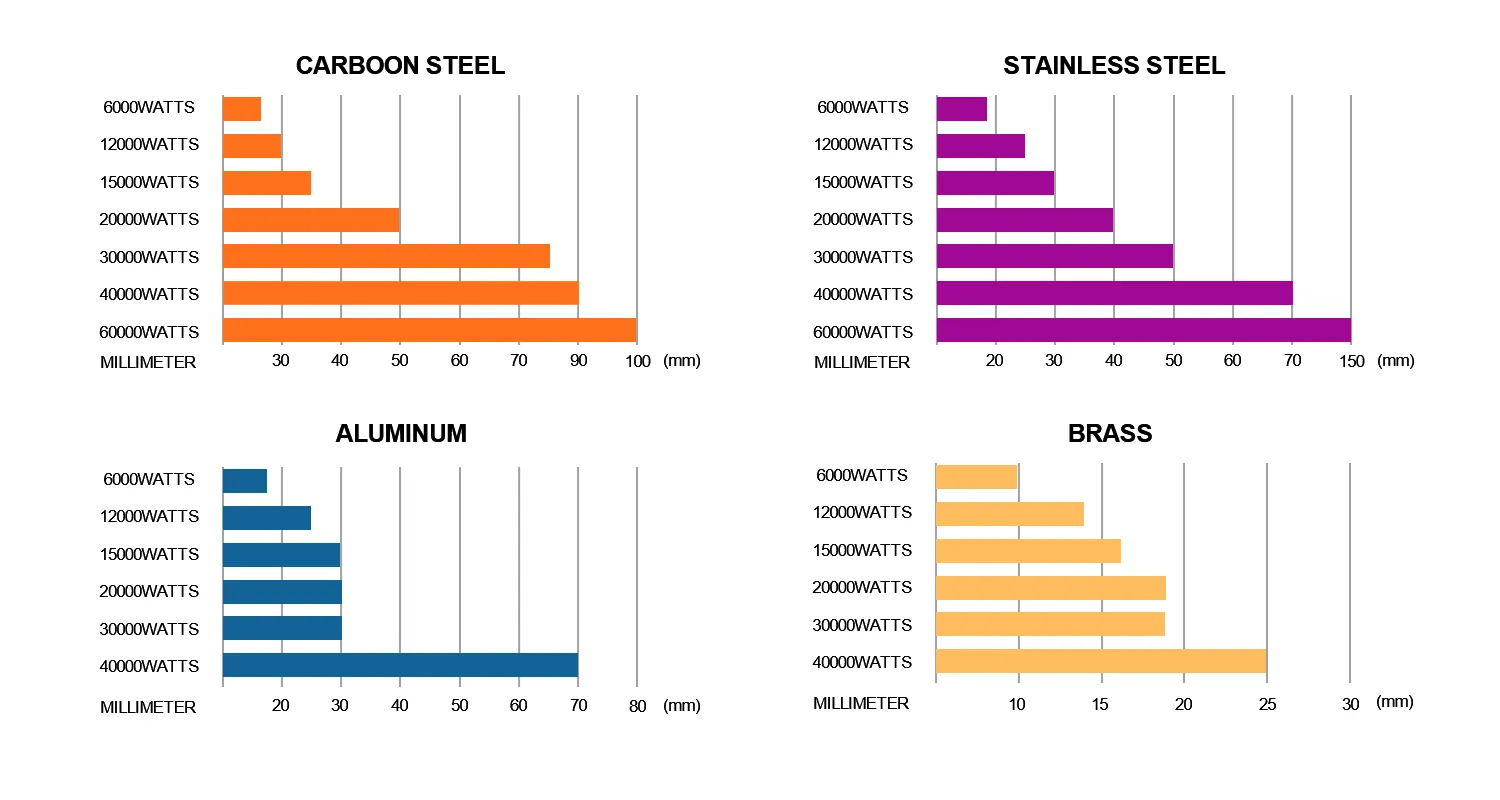

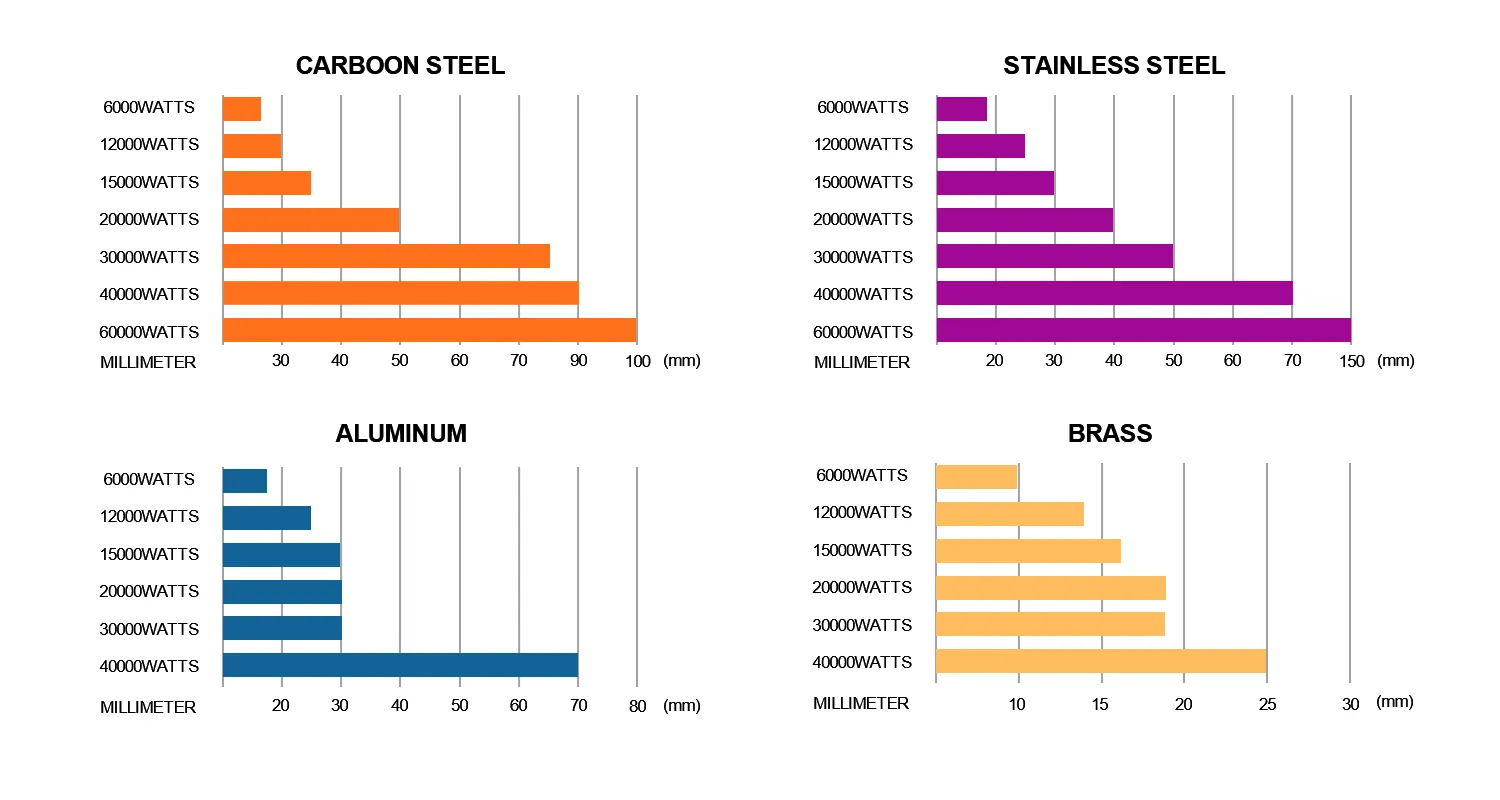

Cutting Parameters:

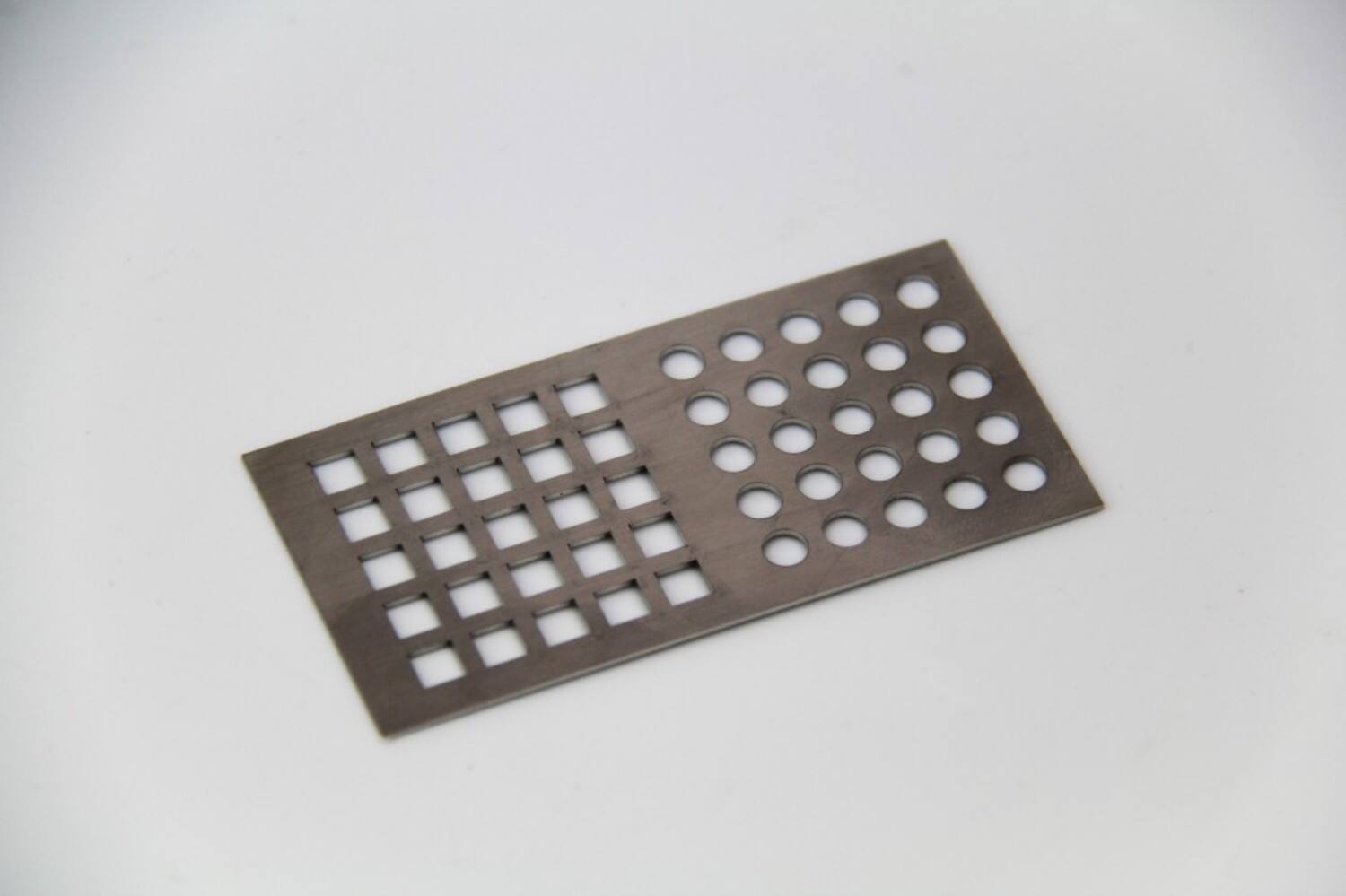

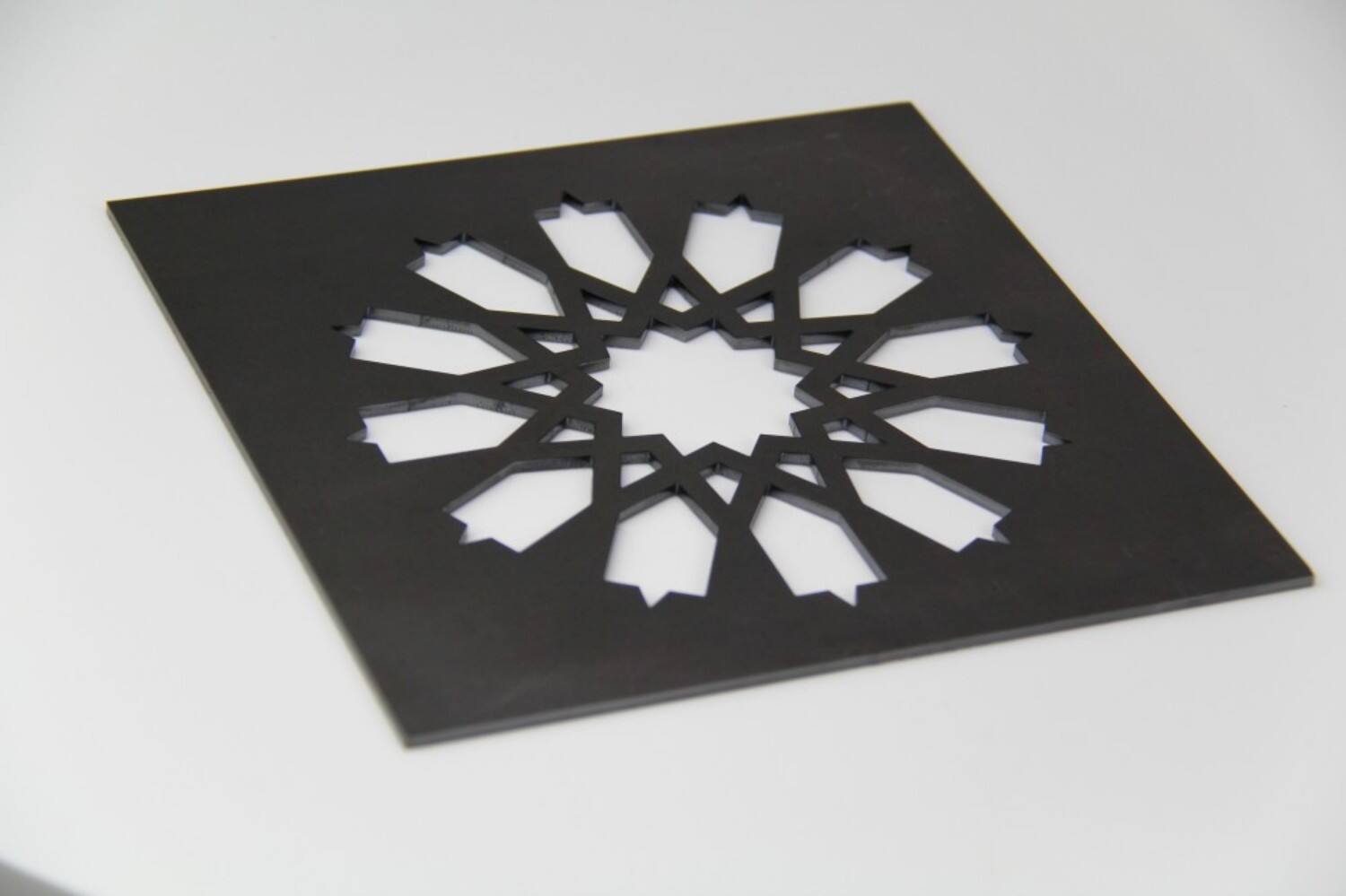

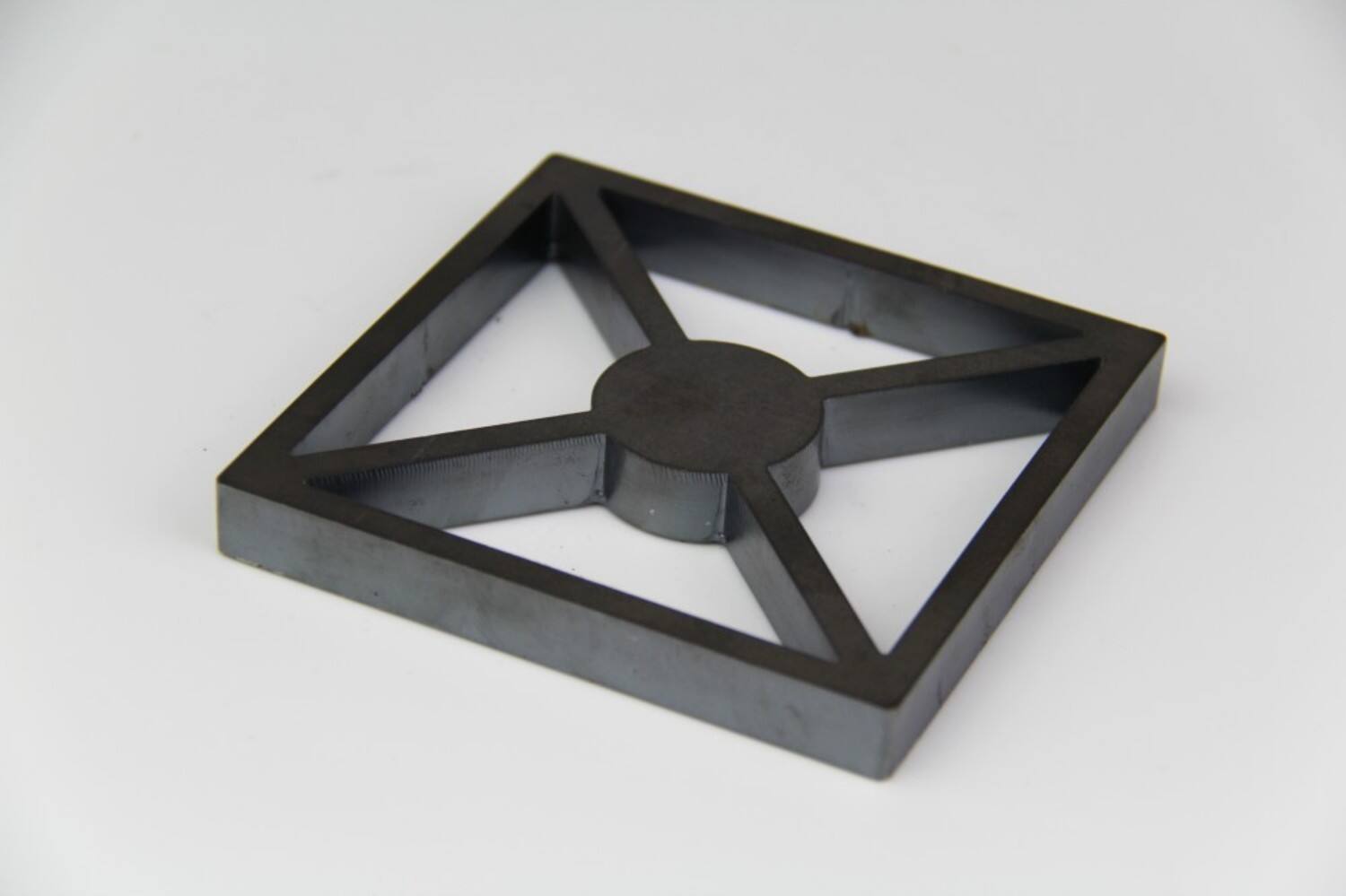

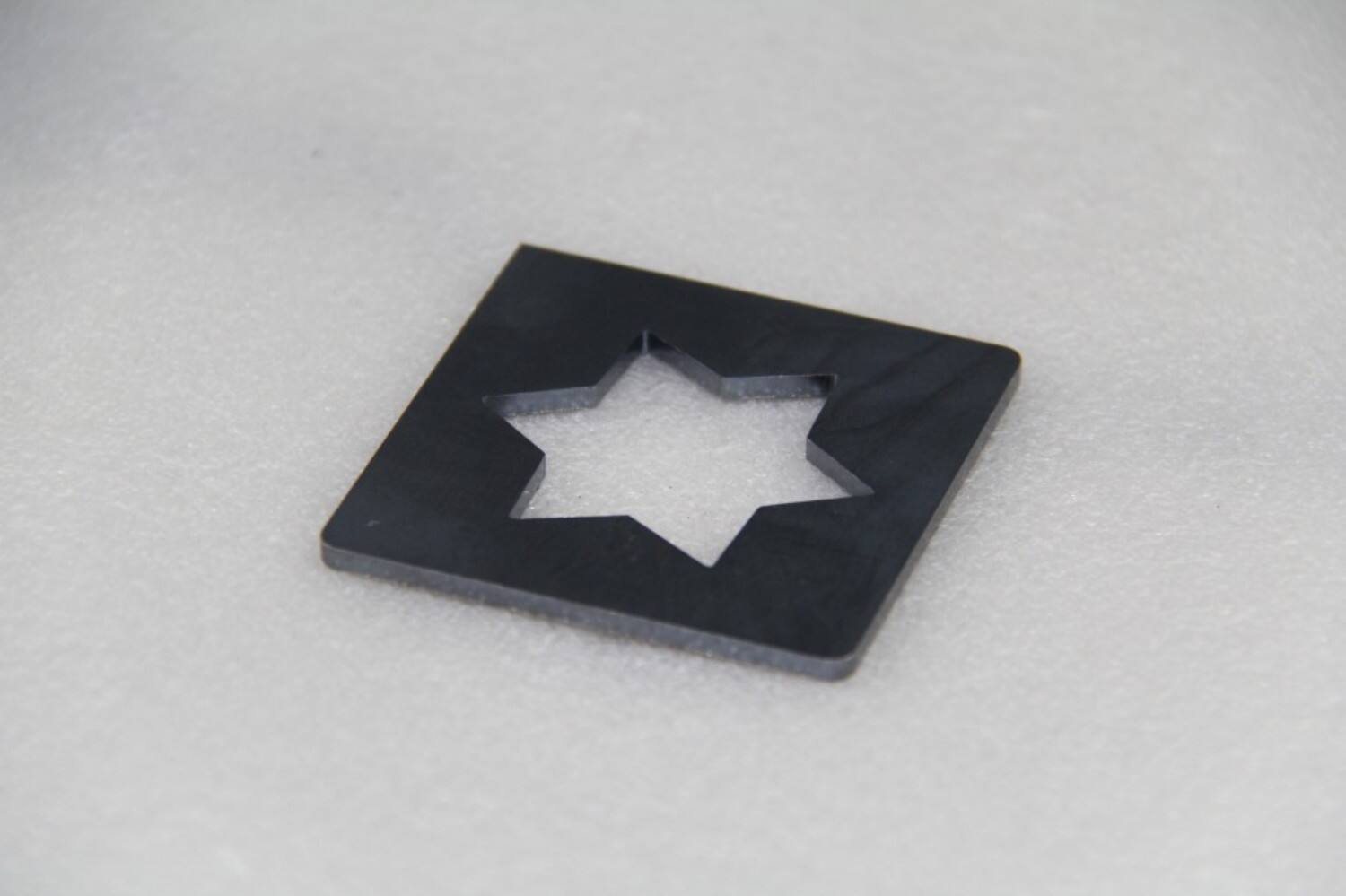

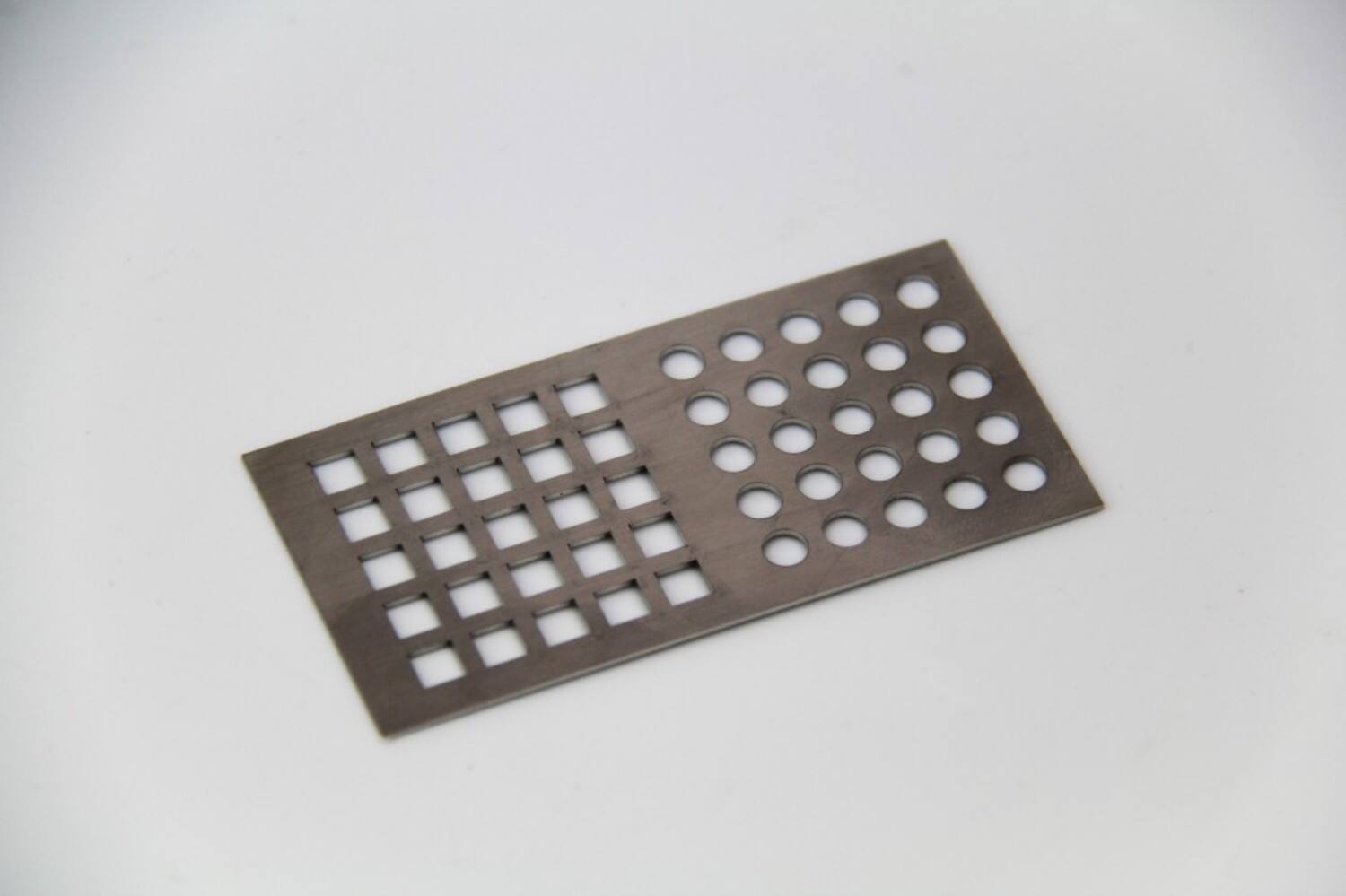

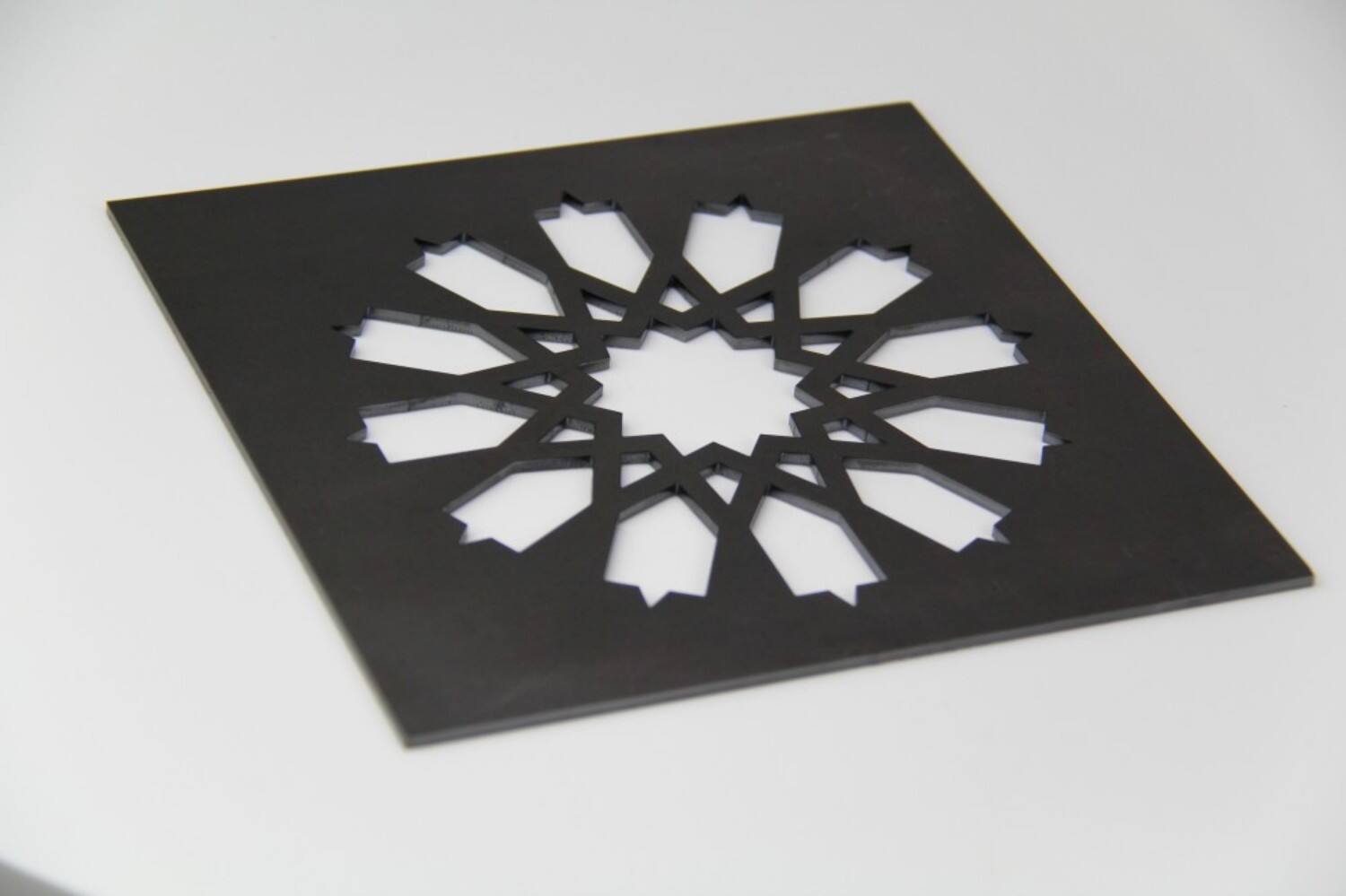

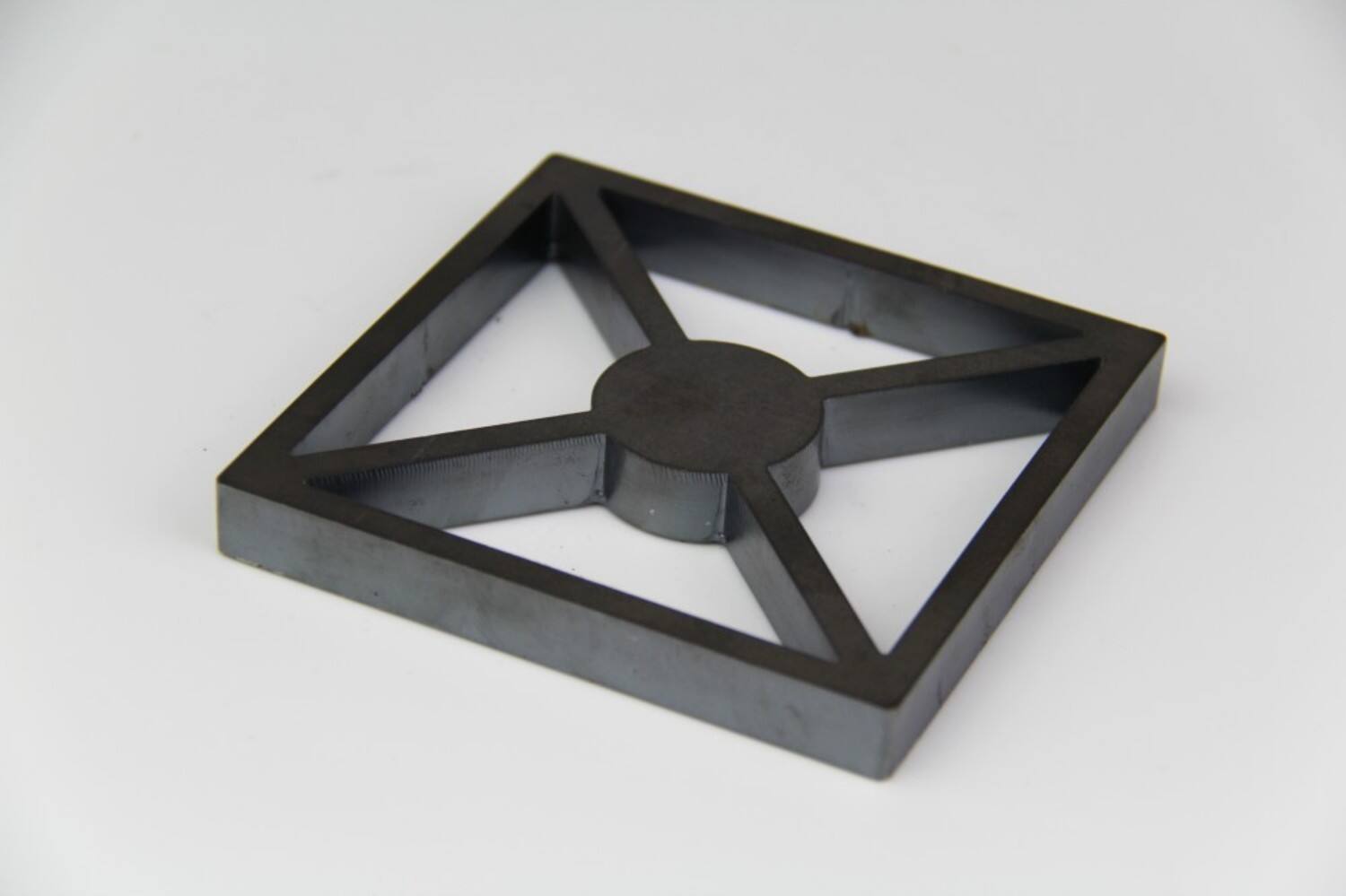

Cutting Samples:

High-Quality Components for Reliable Performance

- Laser Source: Raycus, Max, RECI, or IPG for reliable cutting across different metals.

- Laser Head: BOCI / RAYTOOLS with automatic focusing, anti-collision design, and intelligent sensors.

- Motors & Drivers: DELTA, Fuji, or Yaskawa for precise motion control.

- Electrical Components: Schneider and Omron for stable, safe, and high-performance operation.

- Control System: FSCUT, supporting CAD/DXF, one-stroke flying cuts, and multi-task processing.

- Cooling: Water chiller system protects the laser head and source, with alarm for high temperatures.

- Automatic Lubrication: Adjustable frequency and quantity for extended machine life.

Specifications and Performance

With a cutting area of 3000 × 1500 mm, the 3015LS can handle sheet thicknesses up to 50mm. Laser power options from 1.5KW to 30KW ensure flexibility for various industrial needs. Fully automated lubrication, high-speed servo motors, and gantry double-drive structure make the machine suitable for high-volume, precise metal cutting.

Applications and Versatility

Ideal for cutting a wide range of metals including:

- Stainless Steel, Carbon Steel, Aluminum, Brass, Copper, Galvanized Sheet

Industries:

- Automotive & Aerospace

- Engineering Machinery

- Electronics & Home Appliances

- Advertising & Decorative Metalwork

- Panel Beating & Metallurgical Equipment

Applications:

- Sheet metal cutting for complex parts and thick plates

- High-precision components for automotive, aerospace, and machinery

- Fabrication of electrical enclosures and industrial equipment

- Signage, advertising panels, and decorative metal elements

- Efficient high-volume cutting with minimal waste

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Enclosed Cabinet Design: Safe, clean, and energy-efficient operation.

- Zone-Controlled Dust Extraction: Three-zone blow-and-suction system keeps workshop smoke-free.

- High Precision & Stability: Honeycomb carbon bed and reinforced gantry beam ensure consistent accuracy.

- Wide Laser Power Range: 1.5KW – 30KW meets diverse production needs.

- Convenient Operation: Electric workbench, large-span lifting door, and simple material handling.

- Premium Components: Raycus/IPG lasers, BOCI/RAYTOOLS heads, FSCUT control, and Schneider electrical systems.

- Automatic Lubrication & Cooling: Reduces maintenance, extends lifespan, and improves cutting efficiency.

- Versatile Material Capability: Cuts metals up to 50mm thickness with smooth edges and minimal wastage.

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Single Platform Fiber Laser Cutting Machine

- Enclosed CNC Laser Cutting System

- High-Precision Sheet Metal Cutter

-

Industrial Fiber Laser Cutting Equipment