Specifications:

| Model |

HN-FL800A |

| Laser Power |

800W - 2000W |

| Laser Source |

Raycus |

| Laser Type |

Fiber |

| Welding Thickness |

0–15 mm |

| Laser Head |

Au3tech Handheld |

| Control System |

Au3tech |

| Welding Speed |

≤300 |

| Speed Regulation |

PWM open-loop speed regulation |

| Wire Diameter |

0.6 / 0.8 / 1.0 / 1.2 / 1.6 / 2.0 mm |

| Cooling Method |

Air cooling |

| Power Supply |

220V / 50HZ |

| Machine Size |

570 × 500 × 520 mm |

| Gross Weight |

180 kg |

Description:

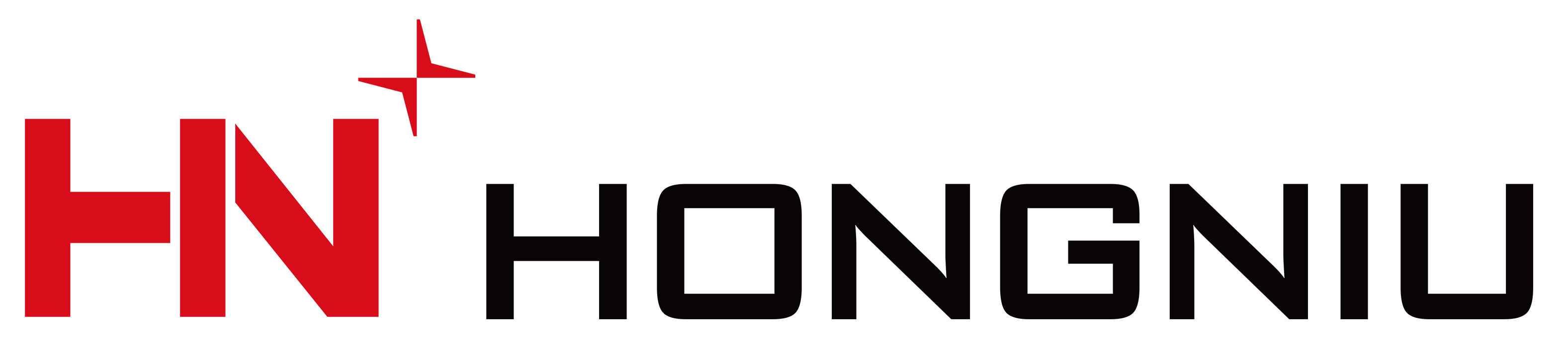

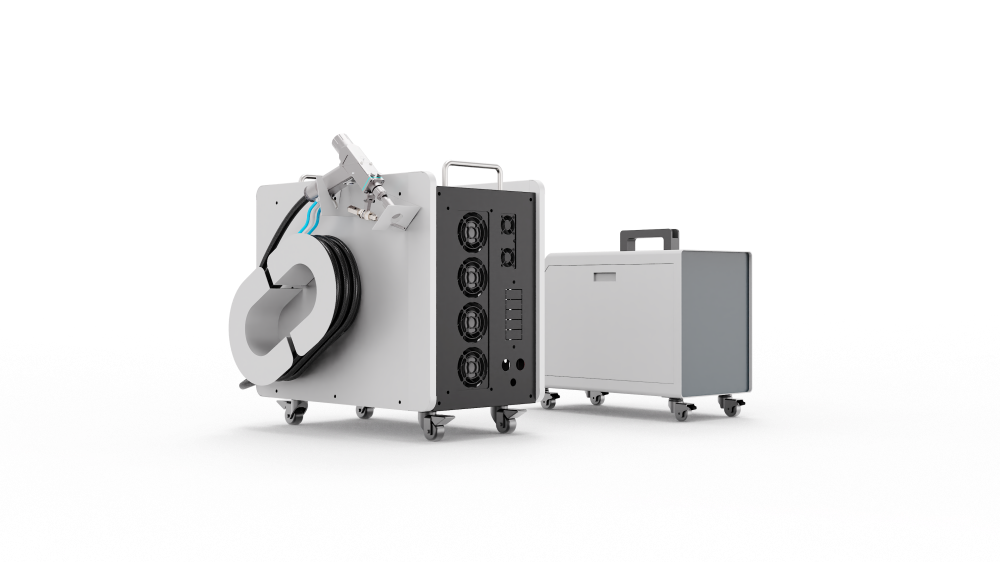

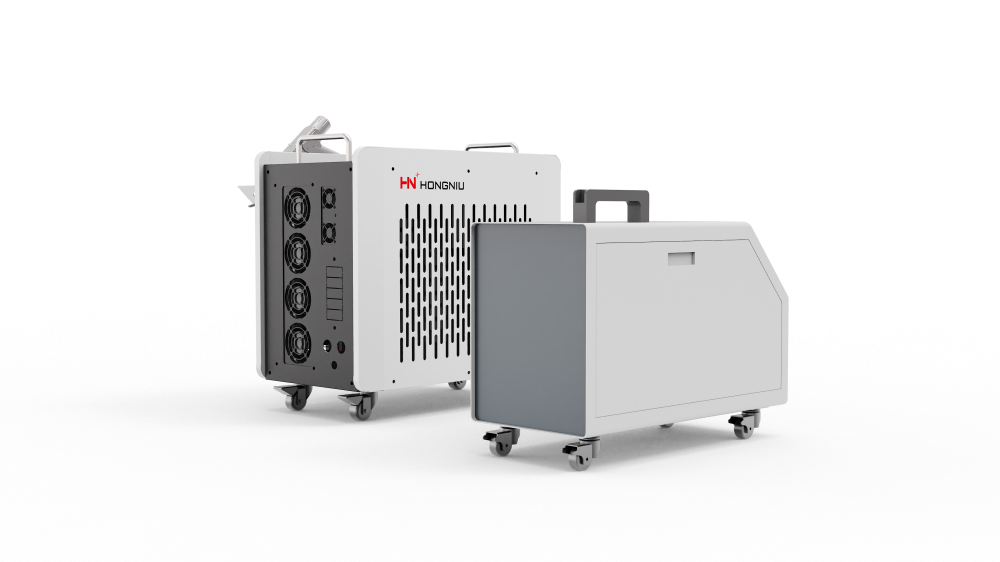

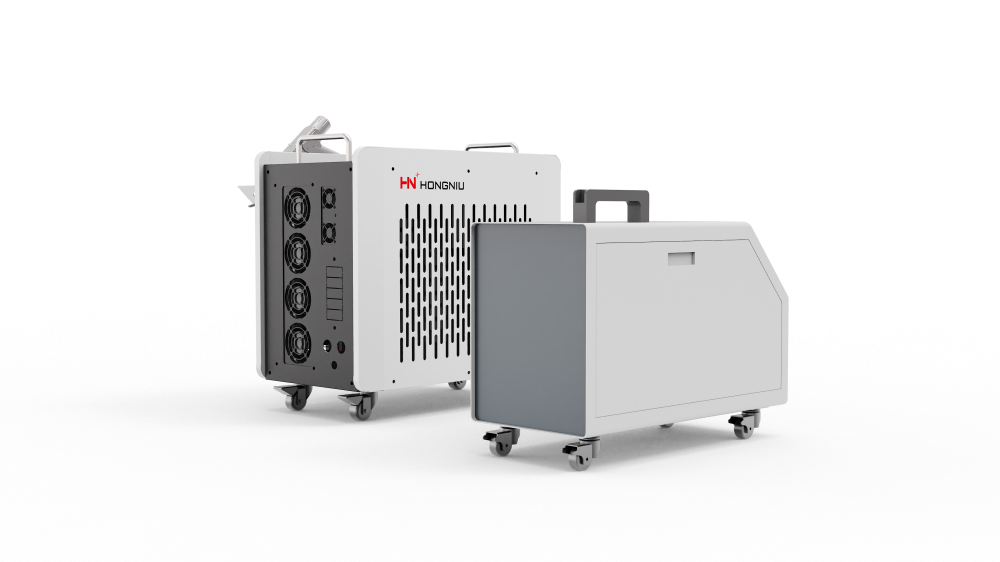

The HN-FL Series Air-Cooled Fiber Laser Welding Machine is a compact, efficient, and easy-to-use solution designed for metal sheet welding applications. By adopting an air-cooled fiber laser system, this machine eliminates the need for bulky water chillers, significantly reducing maintenance requirements and installation space.

With a handheld laser welding head and intelligent control system, the HN-FL series delivers stable welding performance, clean weld seams, and excellent adaptability to various working environments, making it ideal for small and medium-sized fabrication workshops.

High-Quality Components for Reliable Performance

- Laser Source: Raycus fiber laser with stable output and long service life

- Handheld Laser Head: Au3tech welding head supporting welding, cutting, weld cleaning, and remote cleaning via module replacement

- Control System: Au3tech intelligent system with real-time monitoring and multiple safety alarms

- Cooling System: Integrated air-cooling design for simplified structure and low maintenance

- Wire Feeder: Optional dual-wire feeder for thick plates and wide weld seams

Specifications and Performance

The HN-FL series supports welding thicknesses up to 15 mm, depending on material type and laser power. Stable laser output and precise energy control ensure deep penetration, strong weld joints, and consistent welding quality.

The small heat-affected zone significantly reduces deformation and residual stress, resulting in firm welds with minimal or no polishing required.

Applications and Versatility

Applicable Materials:

- Carbon Steel

- Stainless Steel

- Aluminum

- Copper

- Brass

- Galvanized Sheet

The compact body and handheld design allow flexible welding of flat sheets, curved surfaces, corners, and complex structures.

Applications:

- Sheet metal fabrication

- Automotive parts and components

- Electronic and communication equipment

- Medical equipment manufacturing

- New energy and battery industries

- Aerospace and precision metal processing

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Air-Cooled Design: No water chiller required, compact structure, low maintenance

- Portable & Space-Saving: Ideal for workshops with limited space

- High Welding Quality: Smooth, clean weld seams with strong penetration

- Low Heat Input: Minimal deformation and excellent appearance

- Multi-Function Capability: Welding, cutting, and cleaning functions optional

- Low Operating Cost: Fewer consumables and high energy efficiency

- User-Friendly Operation: Stable parameters with high repeatability, reduced operator skill requirements

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Air Cooled Fiber Laser Welding Machine

- Handheld Laser Welder

- Compact Laser Welding Equipment

- Metal Sheet Laser Welding Machine

-

Industrial Fiber Laser Welder