Specifications:

| Model |

HN0516-4 |

| Nominal Pressure |

500 KN - 5000KN |

| Workbench Length |

1600 mm - 3450mm |

| Distance Between Columns |

1230 mm - 5100mm |

| Throat Depth |

260 mm - 550mm |

| Slider Stroke |

200–300mm |

| Max Opening Height |

495–600mm |

| Back Gauge Stroke |

Max 1010mm |

| Main Motor Power |

5.5–63kw |

| Control System |

MT15 (Germany) |

| Compensation System |

Mechanical / Hydraulic |

| Machine Weight |

4000–51000 kg |

Description:

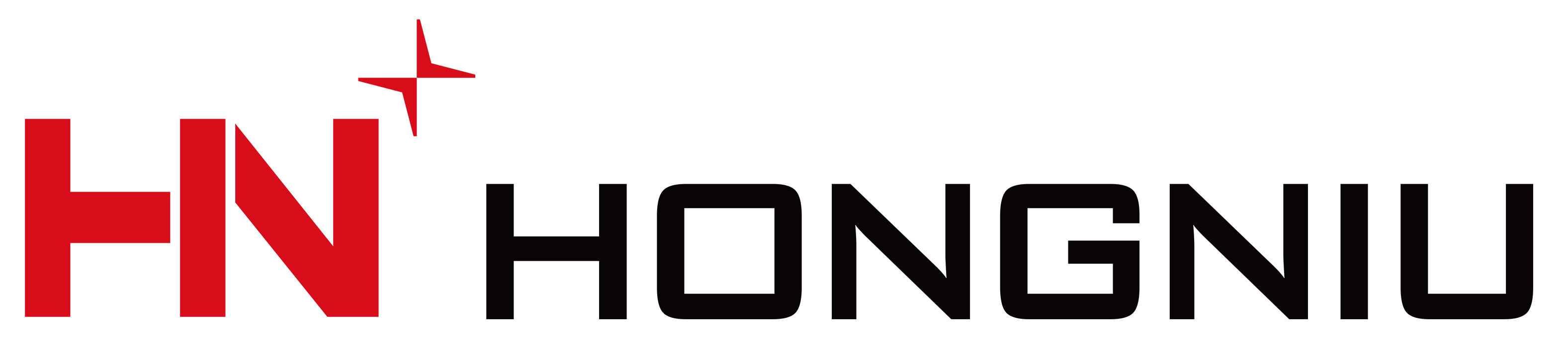

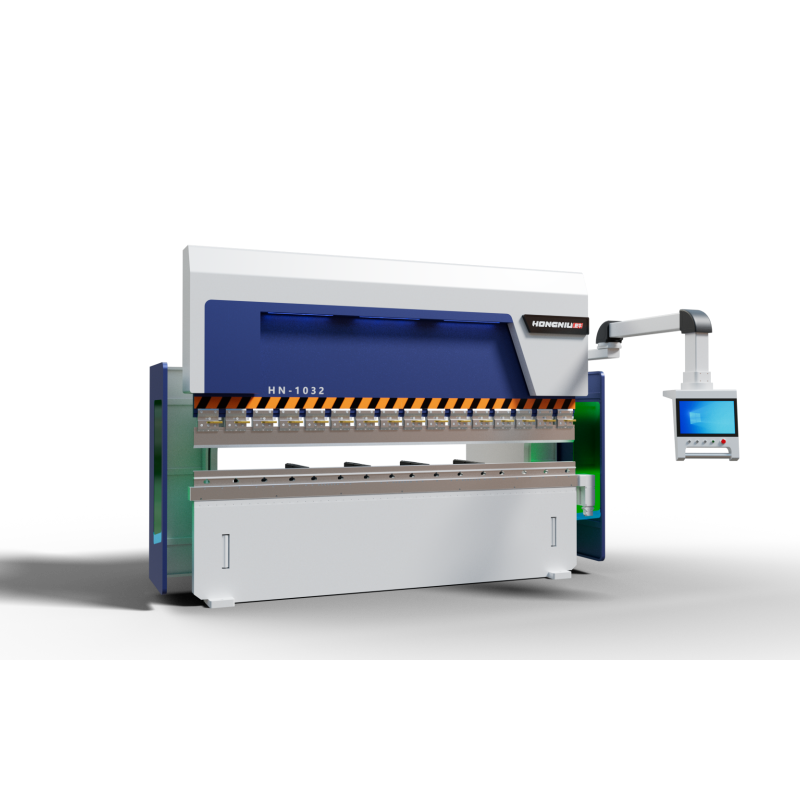

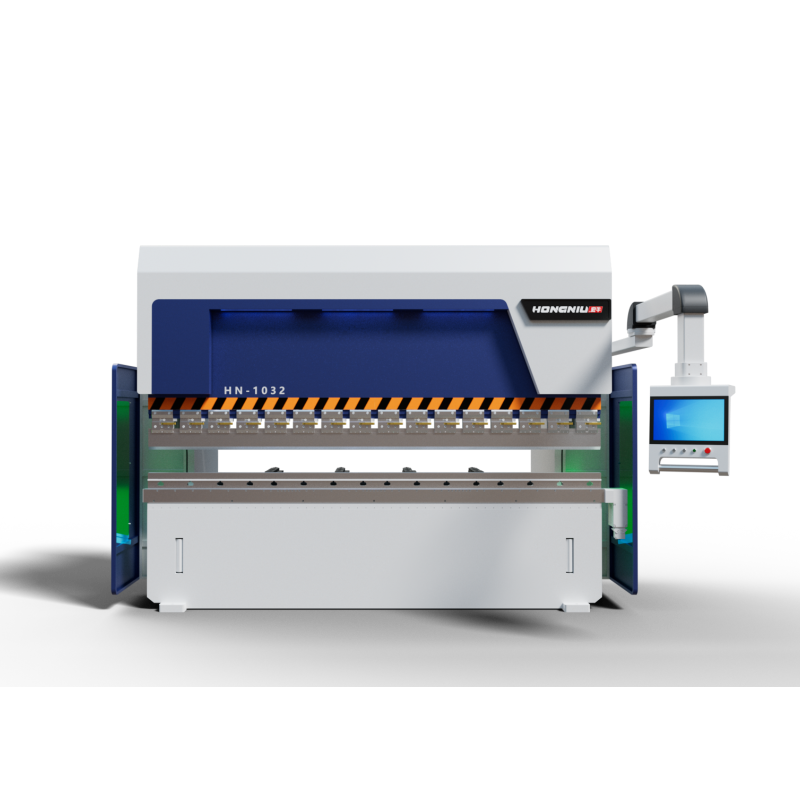

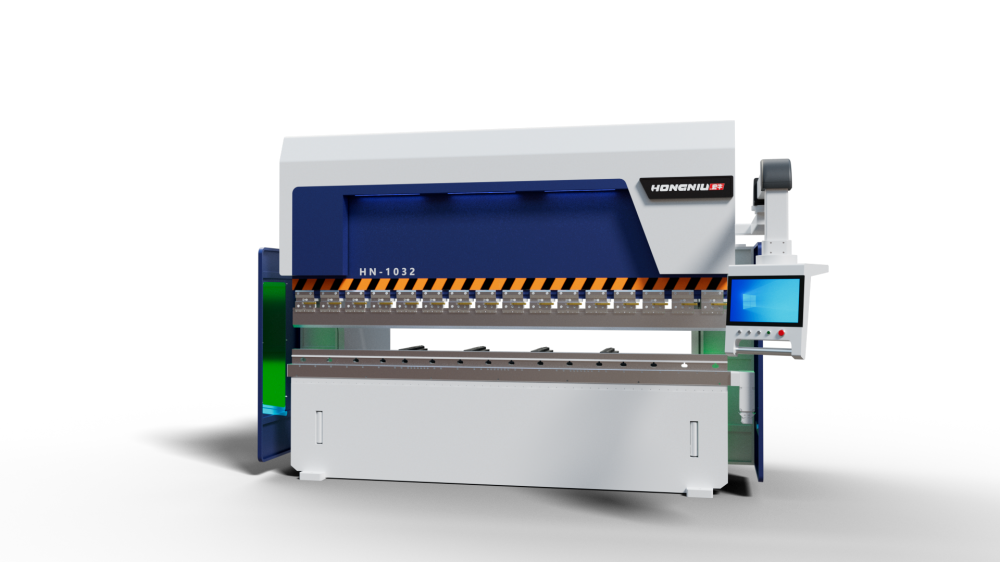

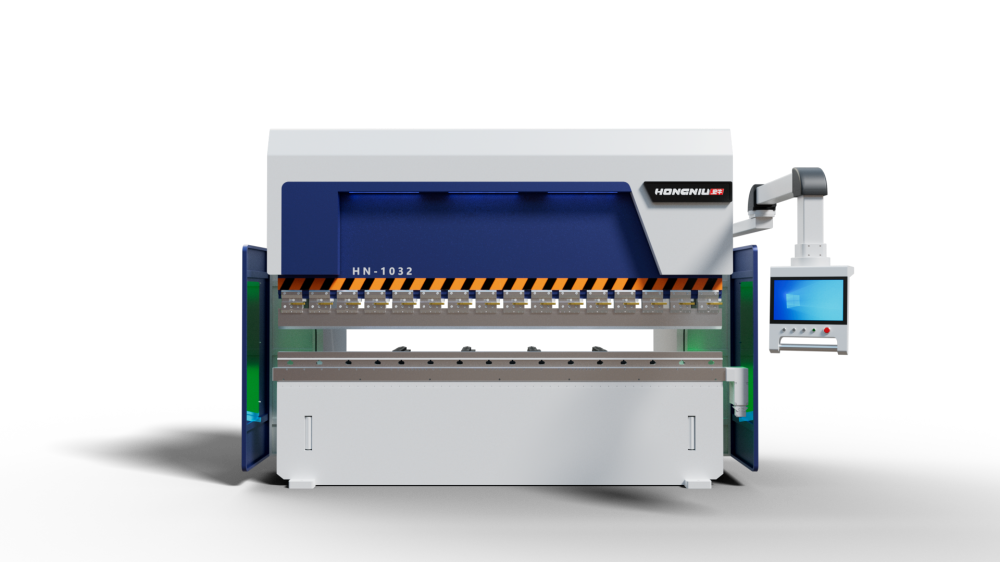

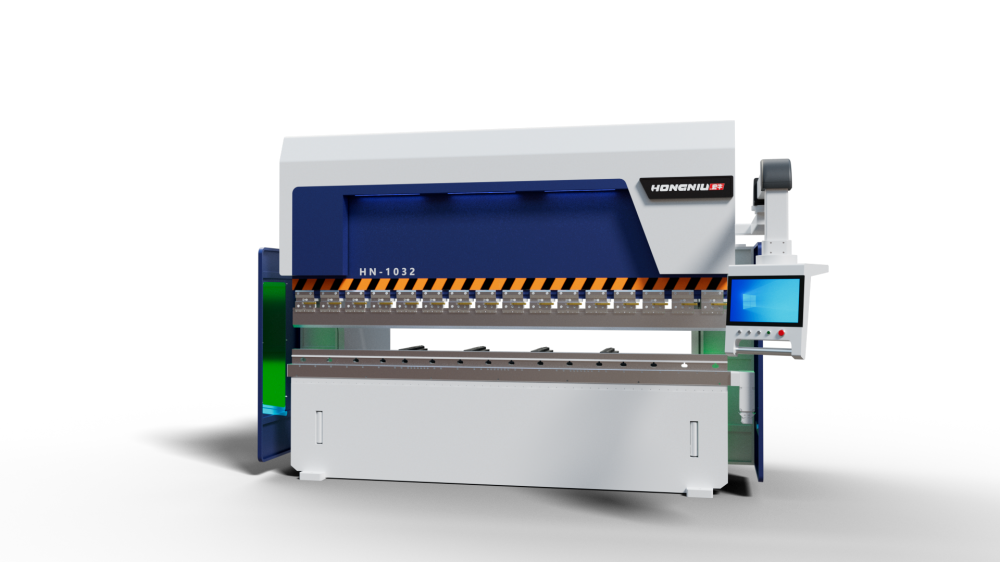

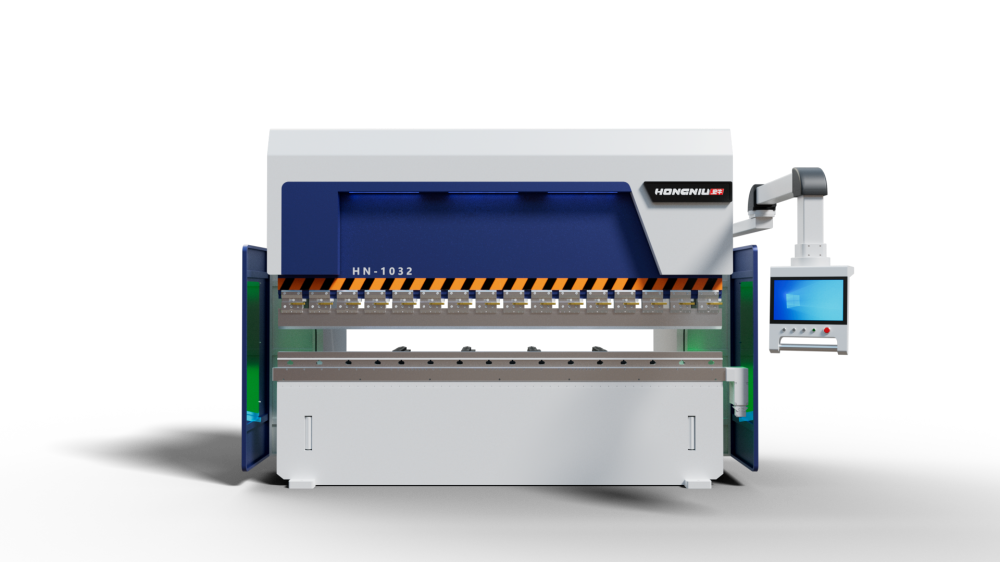

The CNC Bending Machine is a high-performance press brake designed for precision metal forming in modern manufacturing environments. Featuring an oil-electric hybrid servo system, it delivers stable pressure control, high repeatability, and excellent energy efficiency.

With support for multi-axis control and automation interfaces, the HN series is ideal for both standalone operation and integration into automated bending lines.

High-Quality Components for Reliable Performance

- Control System: MT15 CNC controller from Germany for stable and intelligent operation

- Hydraulic Valves: Rexroth (Germany) high-frequency hydraulic valve group

- Proportional Valve: HengLi (USA) for precise pressure regulation

- Linear Encoder: GIVI (Italy) magnetic grid ruler for accurate positioning

- Servo Motors: INOVANCE (China) for X, R, Y axes

- Electrical Components: Schneider for industrial-grade reliability

- Sealing System: NOK (Japan) oil seals for long service life

- Hydraulic System: Parker oil tube connections and SUUNY oil pump

Specifications and Performance

The HN Series provides bending force from 500KN to 5000KN, with high-speed ram movement and precise axis positioning accuracy up to ±0.01 mm on Y axes. Mechanical or hydraulic crowning compensation ensures uniform bending angle across the entire workpiece length.

Energy-saving servo technology reduces power consumption by 50–70% compared to traditional hydraulic press brakes.

Applications and Versatility

Applicable Materials:

-

Carbon Steel

-

Stainless Steel

-

Aluminum

-

Brass

-

Copper

- Galvanized Sheet

Processing Capabilities:

-

Precision sheet metal bending

-

Complex profiles and special-shaped workpieces

-

Large-format and heavy-duty parts

- Automated and robotic bending operations

Applications:

- Sheet metal fabrication workshops

- Automotive and transportation components

- Electrical cabinets and enclosures

- Engineering machinery manufacturing

- Home appliance production

- Aerospace and precision metal industries

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Oil-Electric Hybrid Servo System: High precision with significant energy savings

- Closed-Loop Pressure Control: Stable and repeatable bending accuracy

- Automation Ready: Supports robot integration and automated production lines

- Large Processing Space: Long stroke and high opening for oversized parts

- Fast Tool Change: Standard quick clamp, optional hydraulic clamping

- High-End Components: Rexroth valves, Schneider electrics, GIVI encoders

- Wide Model Range: 500KN–5000KN to meet diverse production needs

- Low Noise & Smooth Operation: Quiet pressure return and servo control

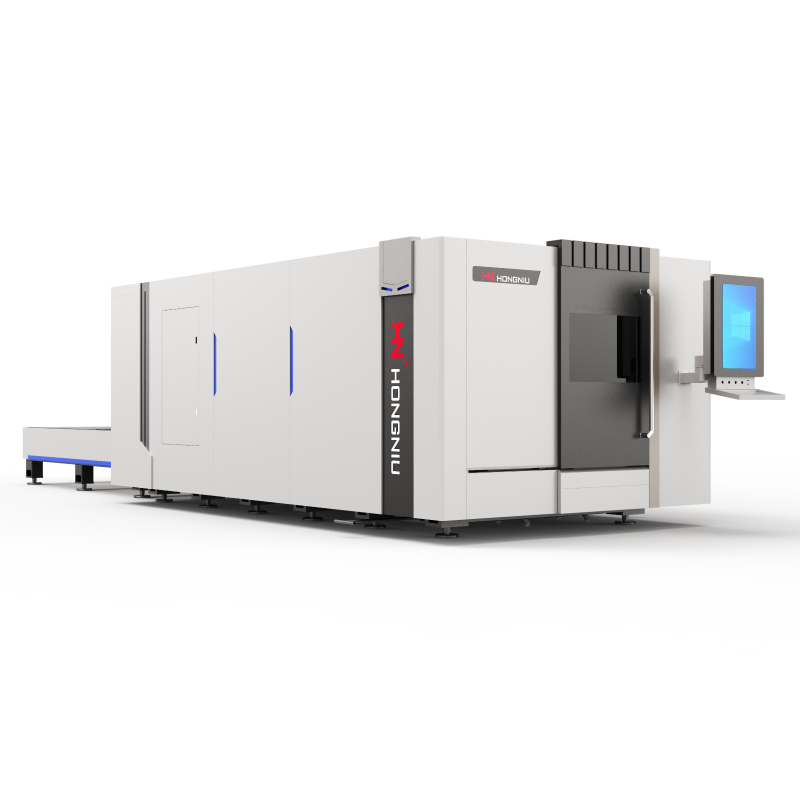

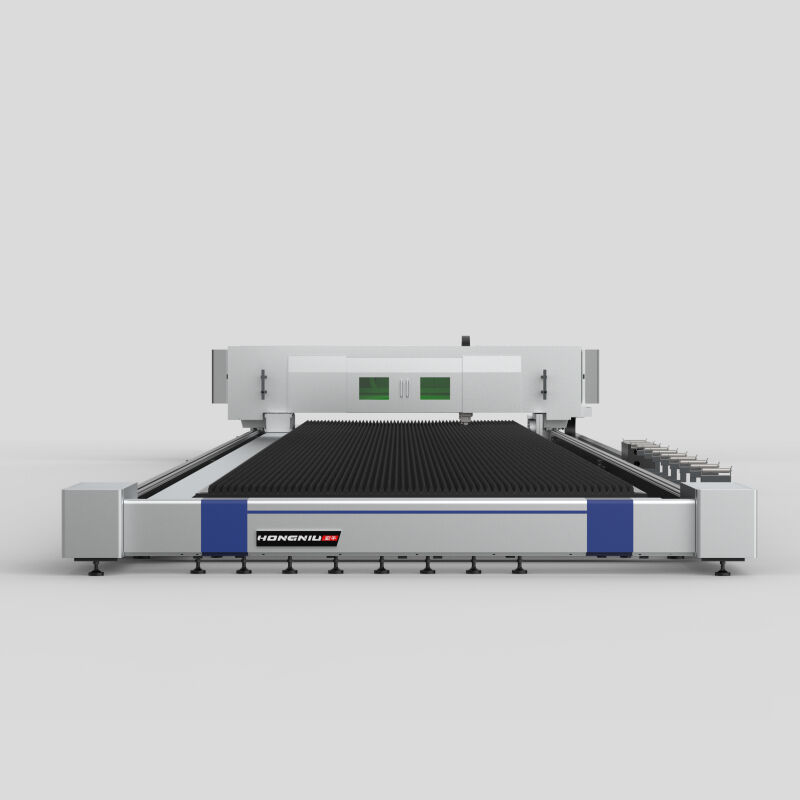

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- CNC Bending Machine

- Servo Hydraulic Press Brake

- Sheet Metal CNC Press Brake

- High Precision Metal Bending Machine

-

Industrial CNC Press Brake