Specifications:

| Model |

HN-14032LM |

| Working Area |

14000 × 3200 mm |

| Laser Power |

6kw–60kw |

| Laser Type |

Fiber Laser |

| X-axis Travel |

3200 mm |

| Y-axis Travel |

14000 mm |

| Z-axis Travel |

140 mm |

| Positioning Accuracy |

±0.03 mm/1000 mm |

| Re-positioning Accuracy |

±0.02 mm/1000 mm |

| Max Running Speed |

150 m/min |

| Max Acceleration |

1.4G |

| Voltage |

3-phase 380V 50/60Hz |

| Cutting Ability |

0–80 mm |

| Machine Size |

16000 × 4500 × 1800 mm |

| Product Weight |

9–15 tons |

Description:

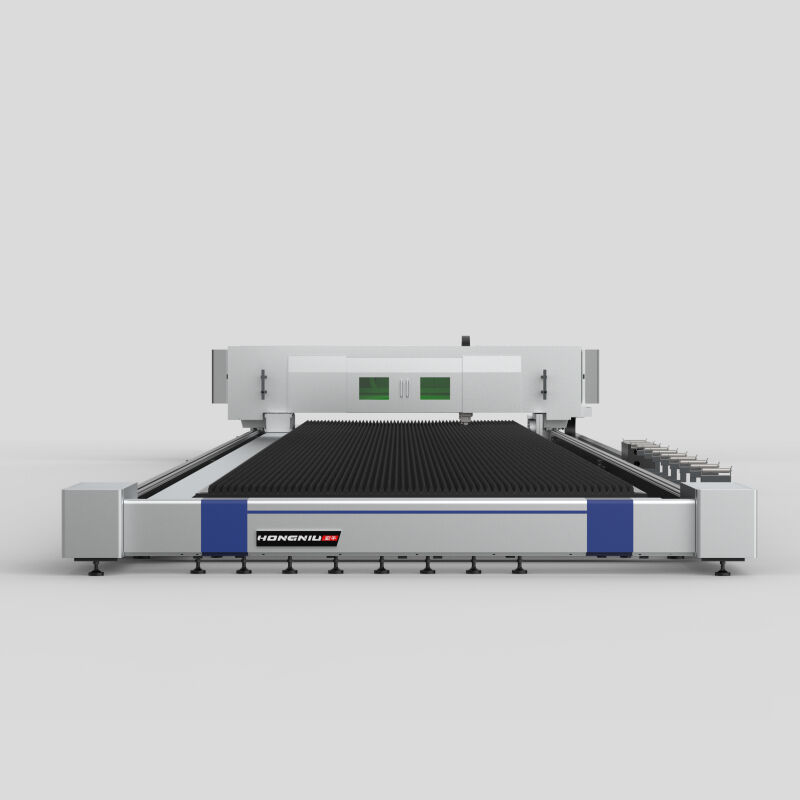

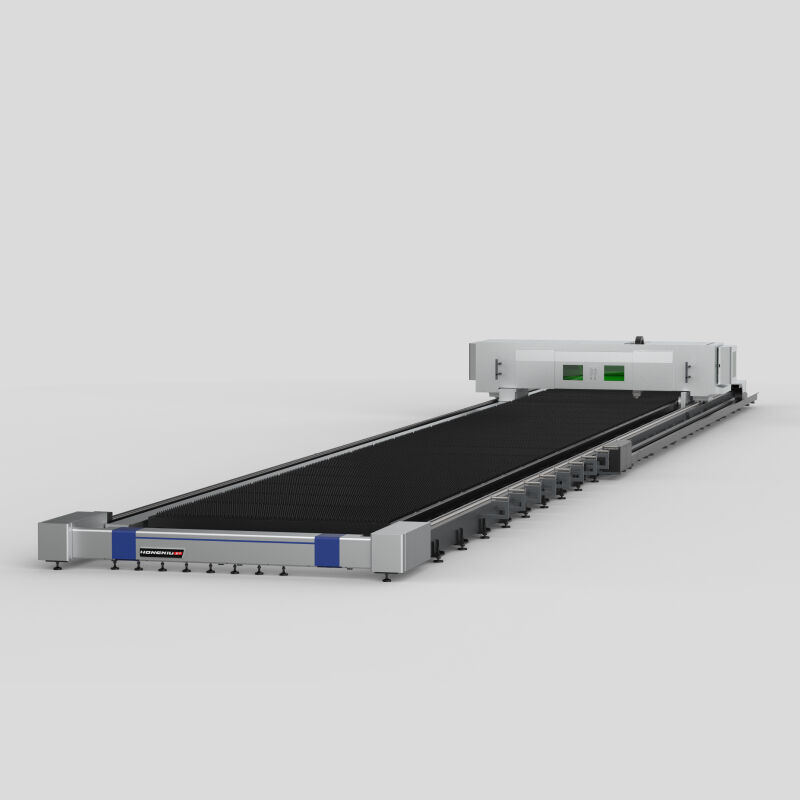

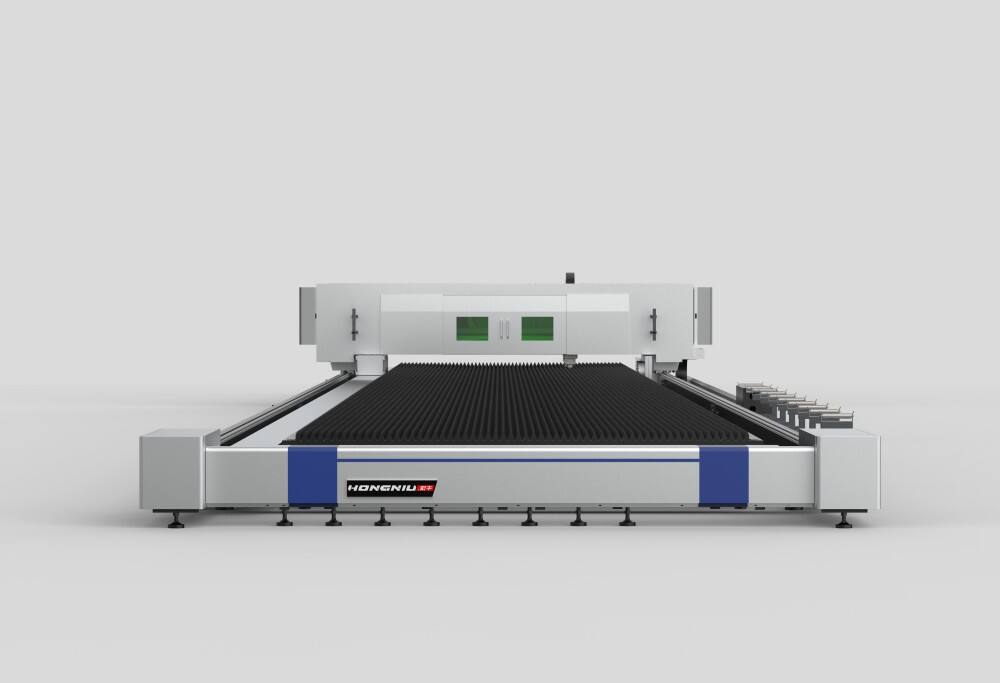

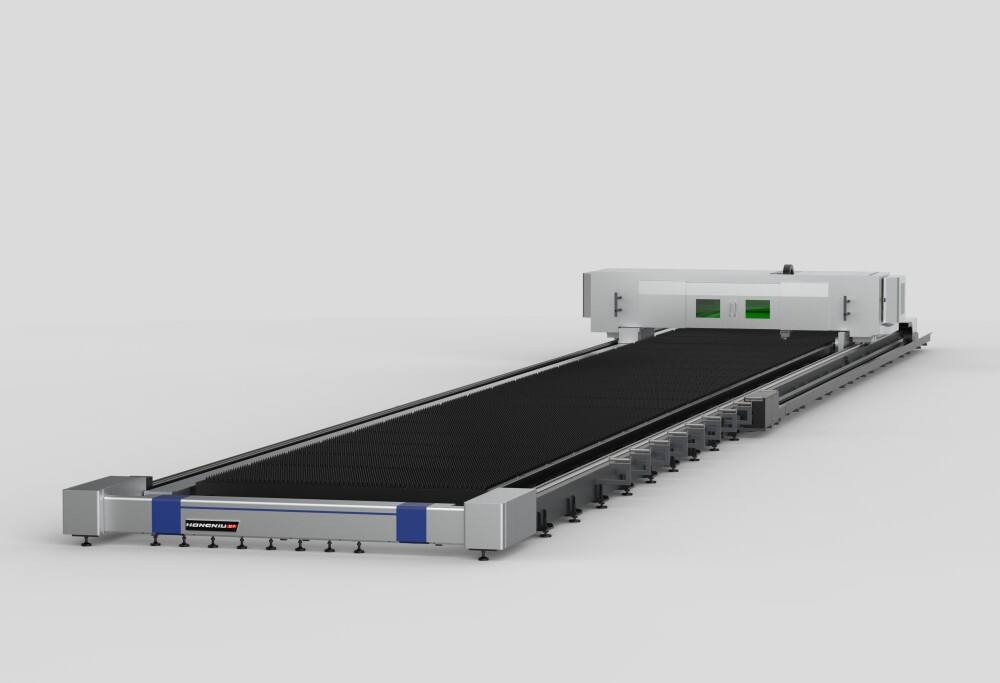

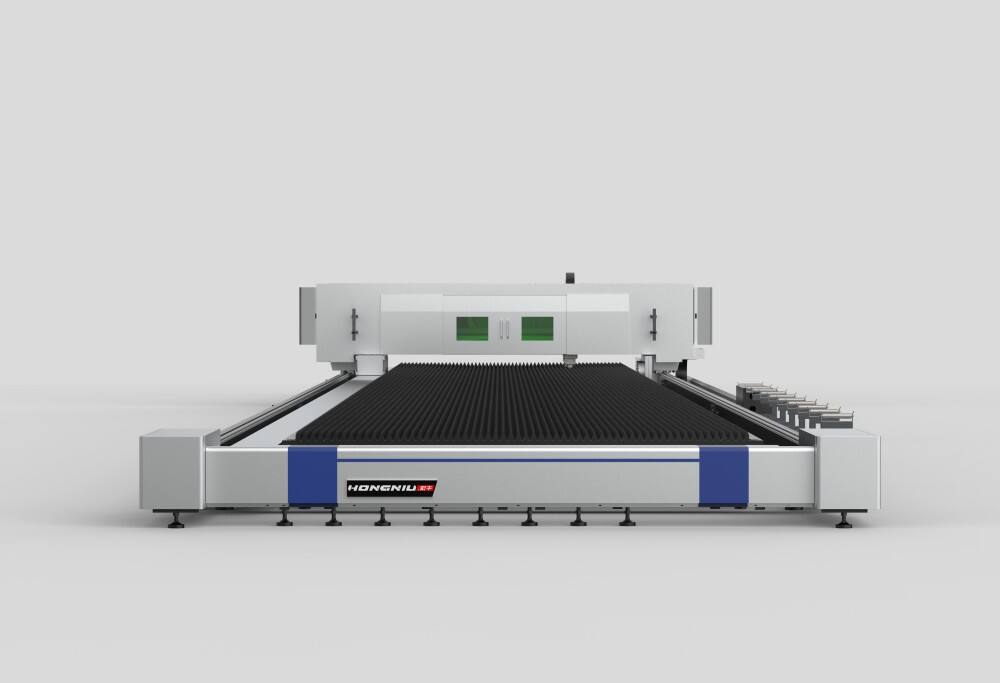

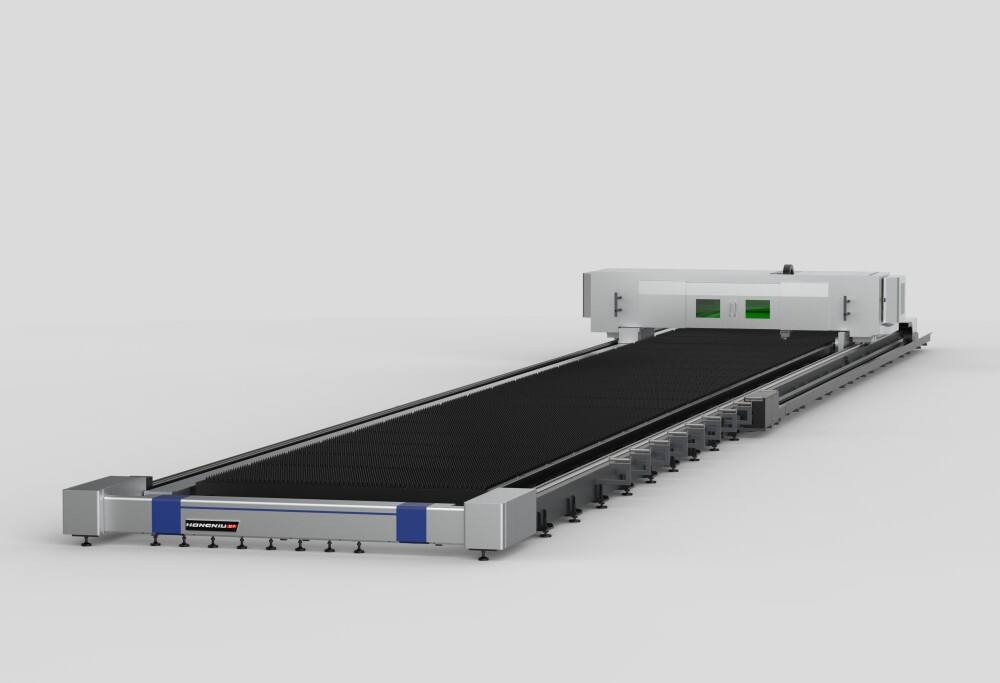

Gantry Type Oversize Fiber Laser Cutting Machine – HN-14032LM / HN-26032LM

The HN-LM series is designed for ultra-large-format, high-power industrial applications requiring long travel, high precision, and extreme structural stability. The gantry-type design, smoke-free bedding structure, and industry-leading safety system make it ideal for heavy industrial sheet processing.

Reinforced Bed & Exclusive Structural Design

-

Honeycomb carbon-steel welded bed, annealed & vibration-aged for durability.

-

Patented cross-support structure enhances rigidity and long-travel precision.

-

Independent nail bed reduces thermal deformation from prolonged cutting.

- Detachable frame rail assembly significantly reduces transportation cost.

Oversize Processing Capability

-

Supports 14m and 26m extra-long working formats.

-

Customizable for large machinery, shipbuilding, heavy structures, and oversized plates.

- Smooth and precise long-distance motion control.

Smoke-Free Cutting Environment

-

Smoke-free bedding system ensures clean operation.

- Internal industrial-grade air duct design for dust-free processing.

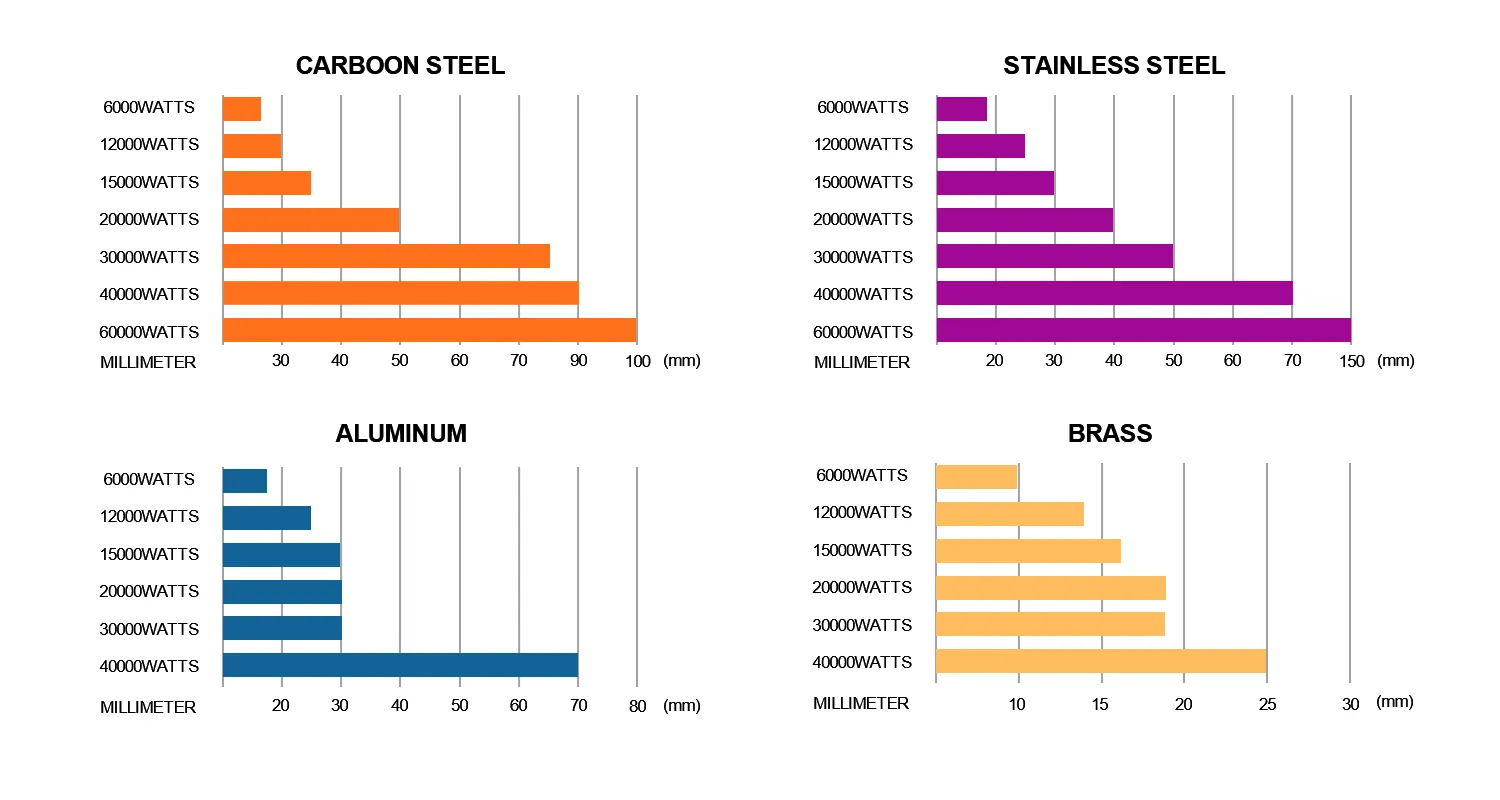

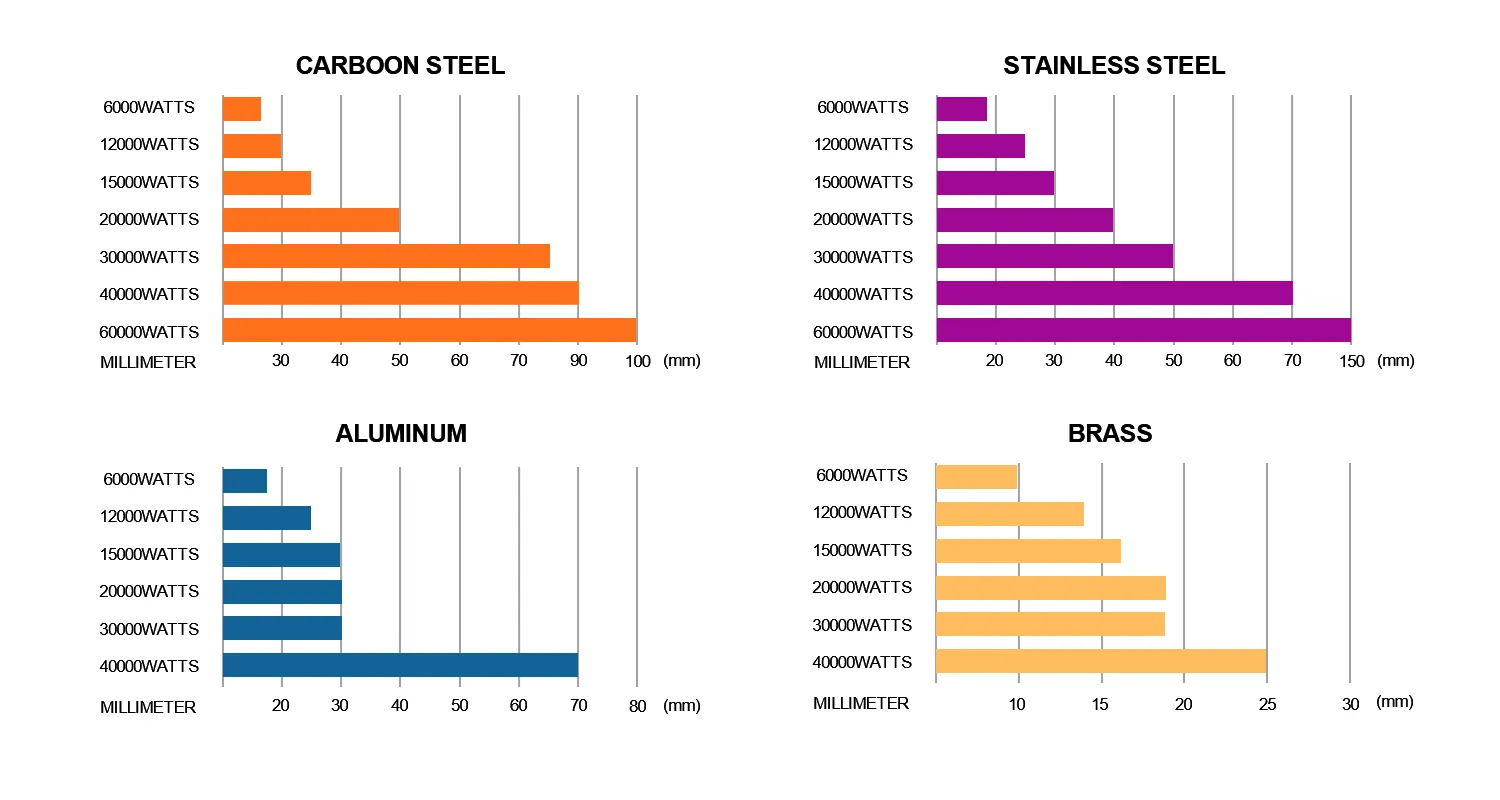

Cutting Parameters:

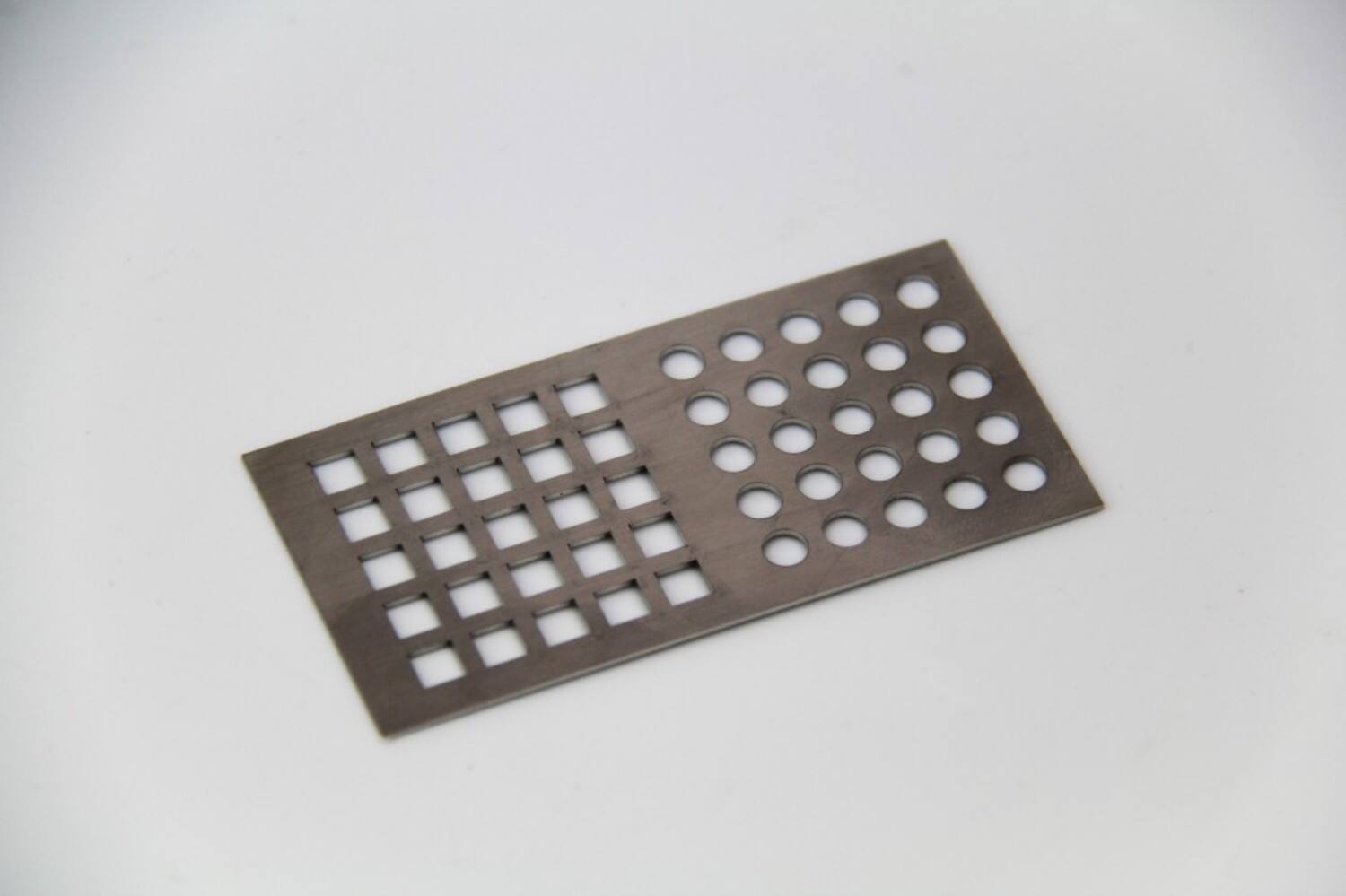

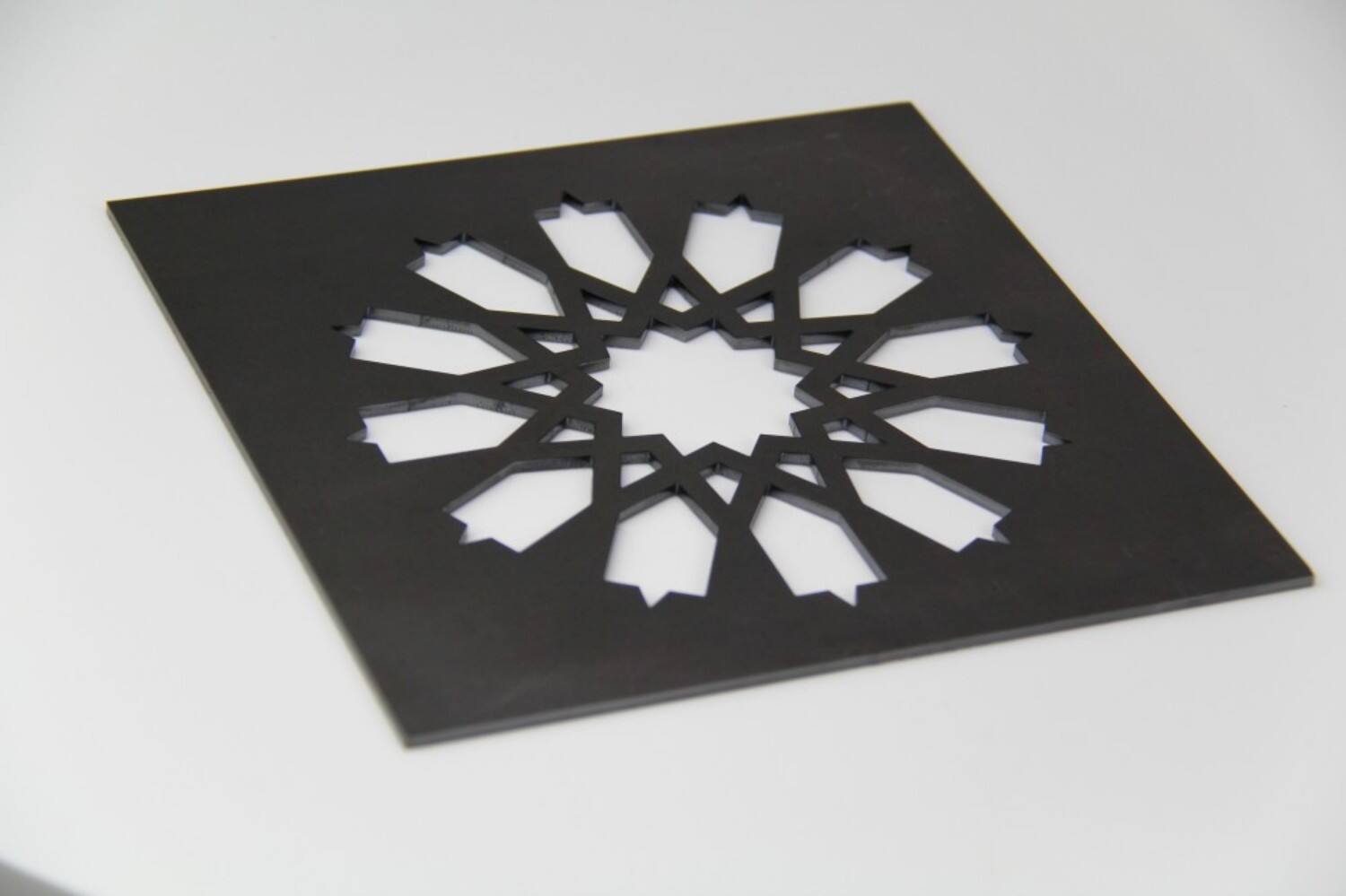

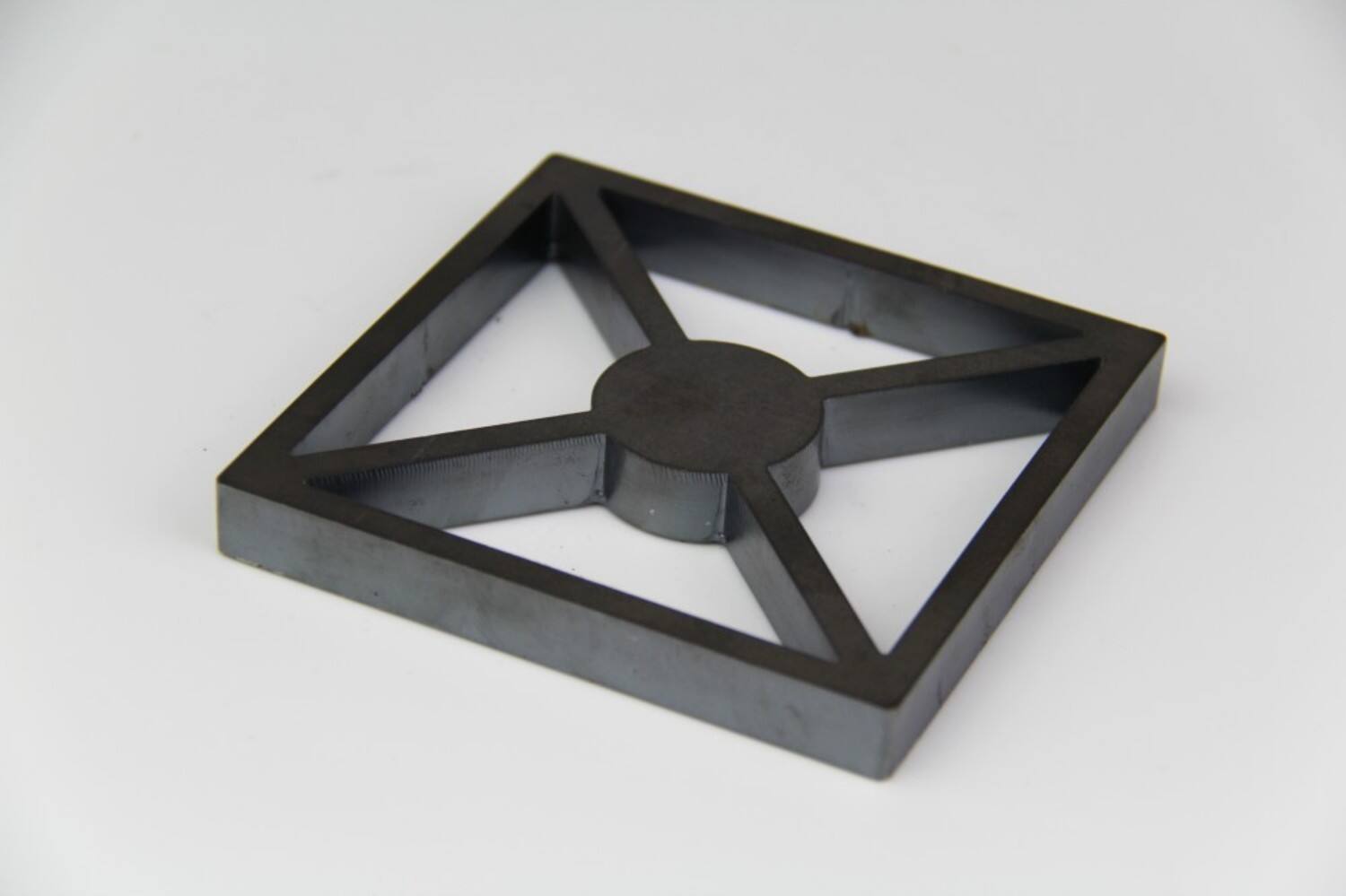

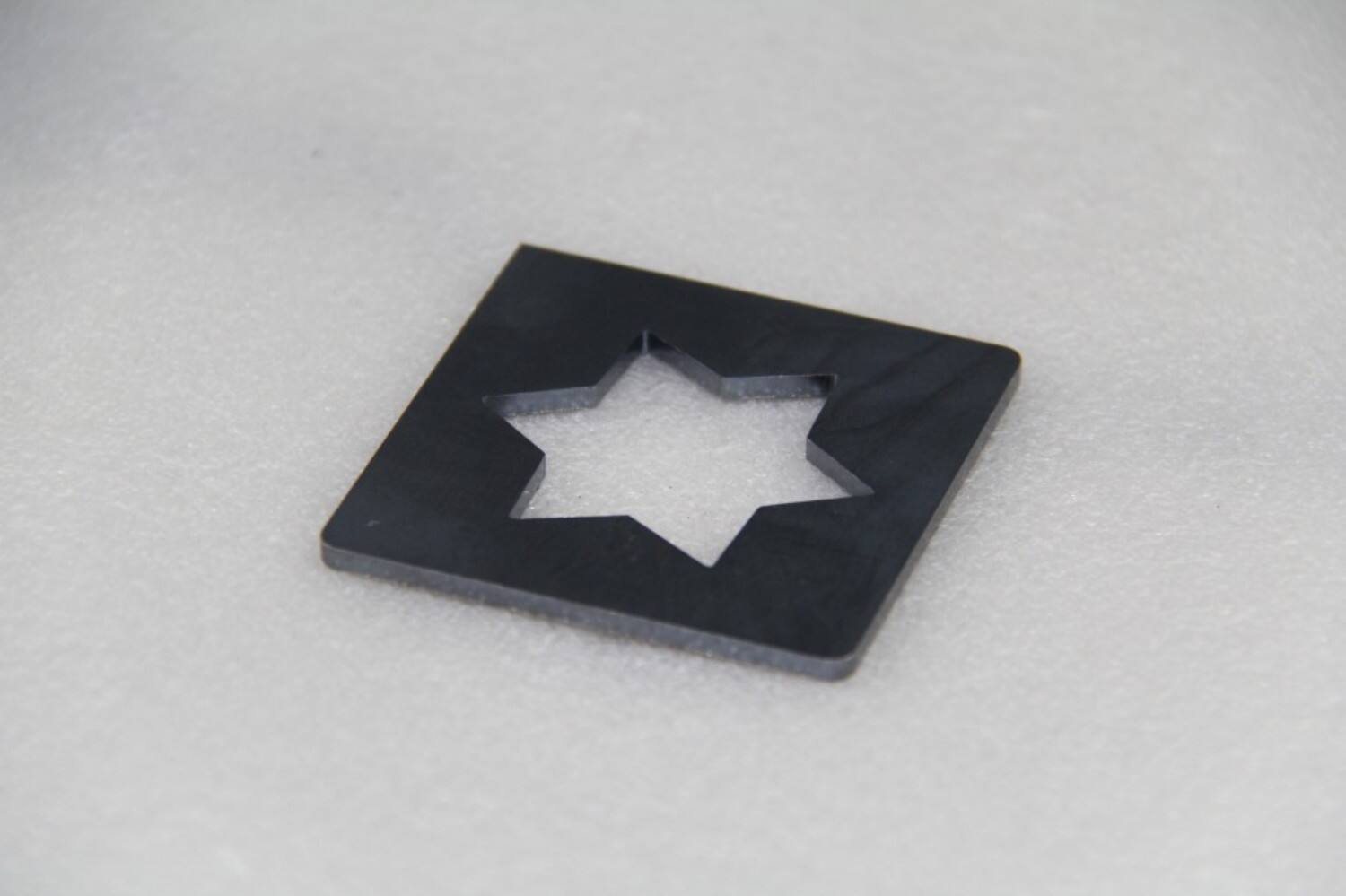

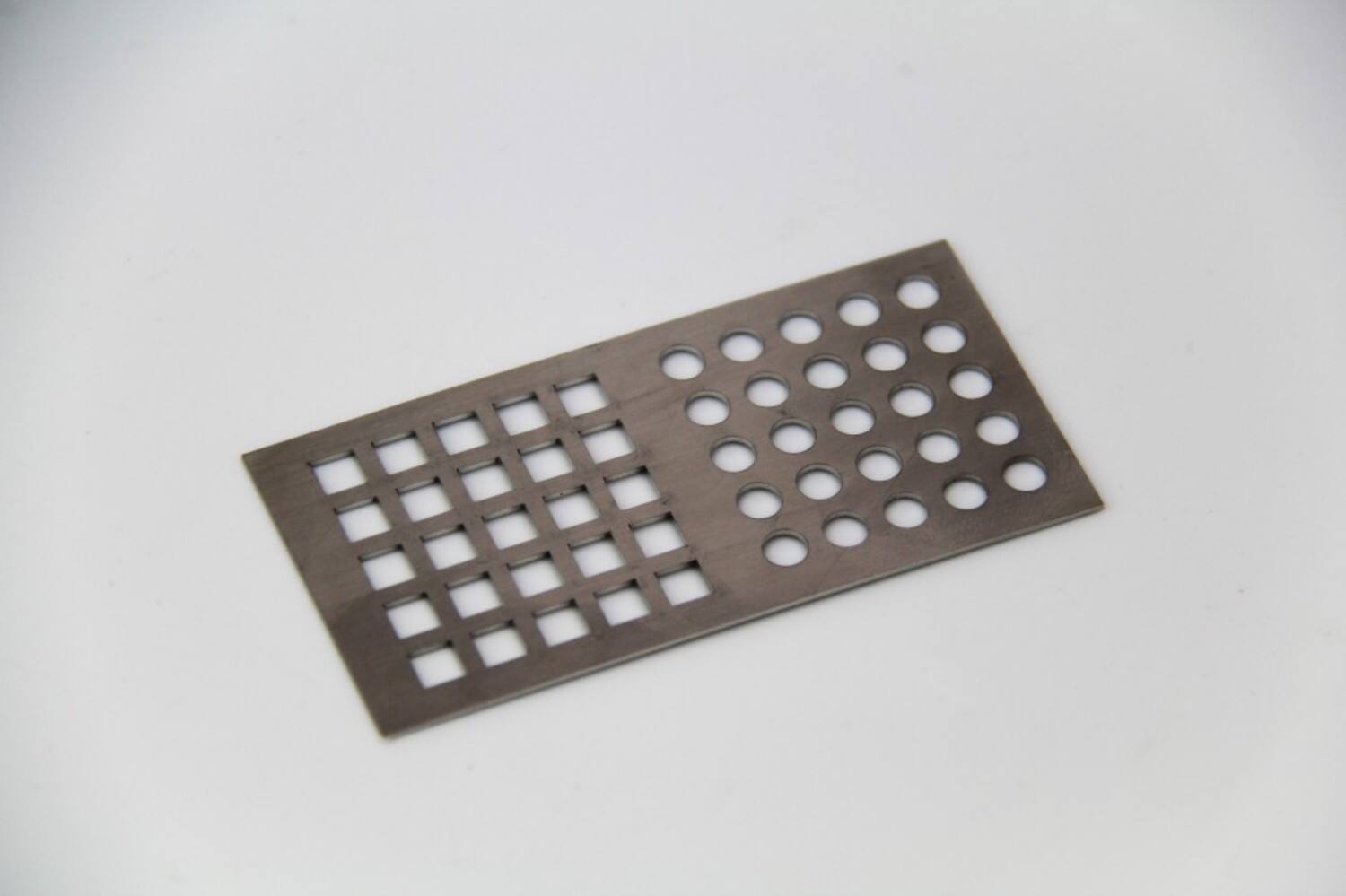

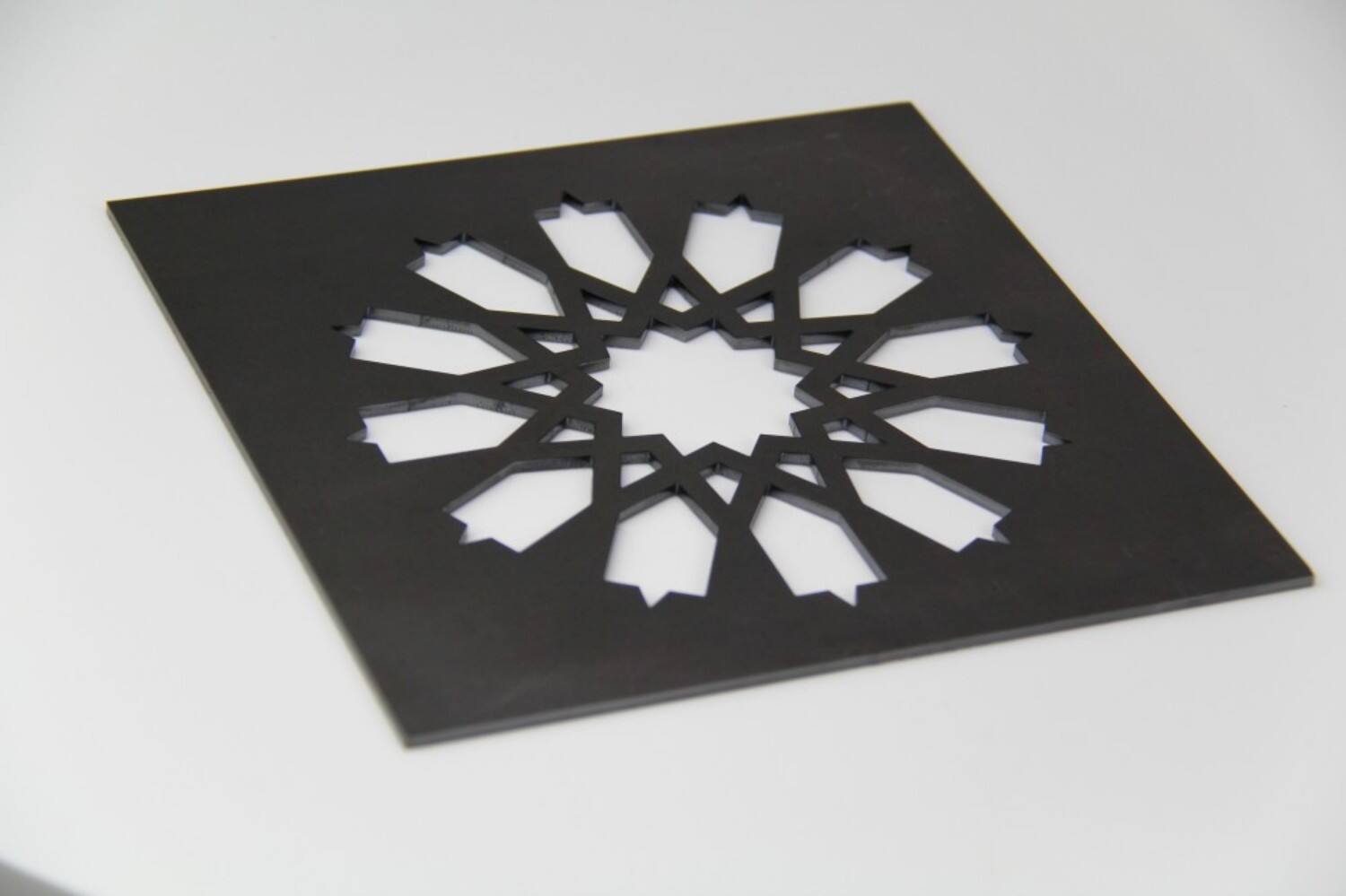

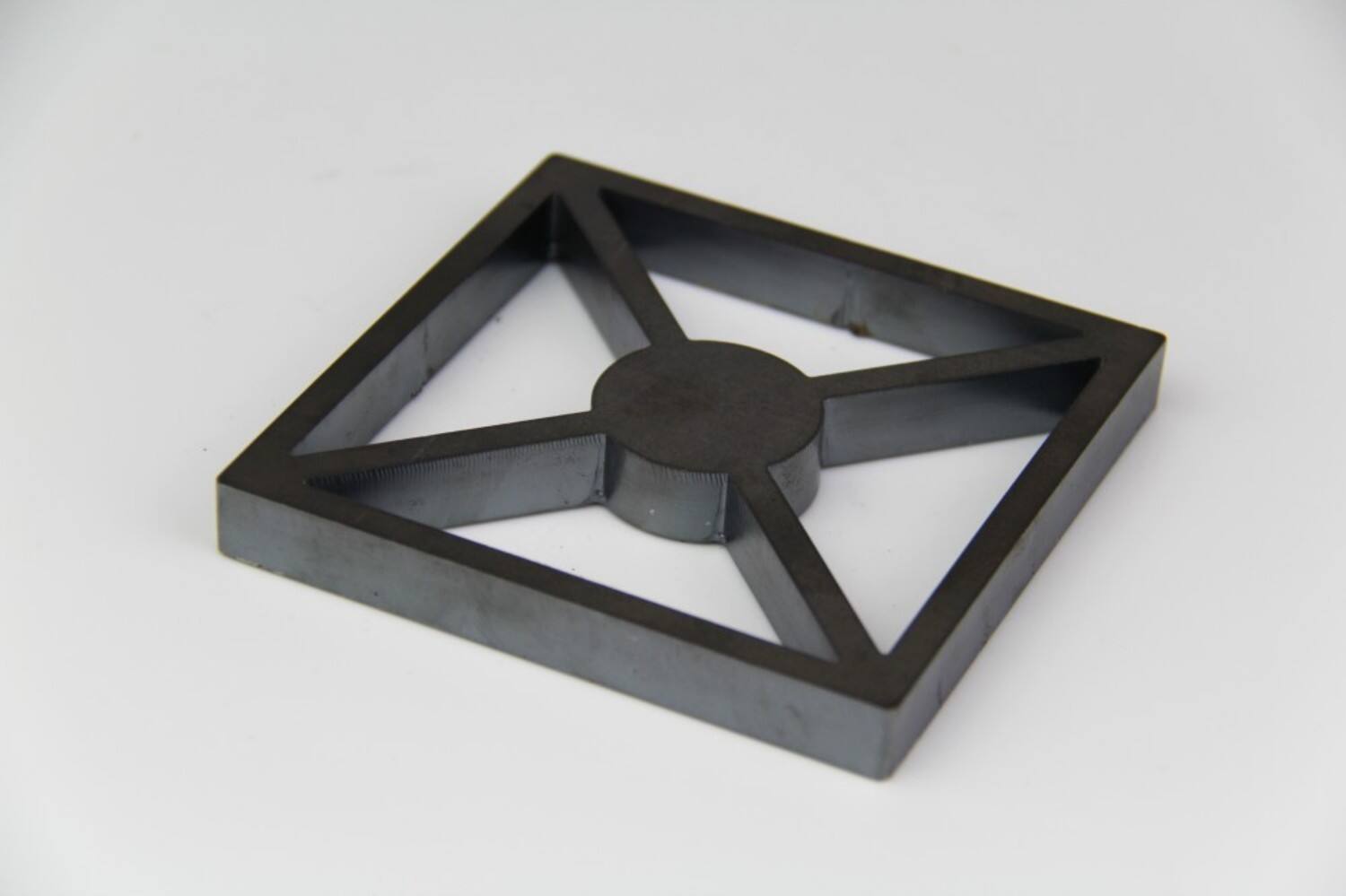

Cutting Samples:

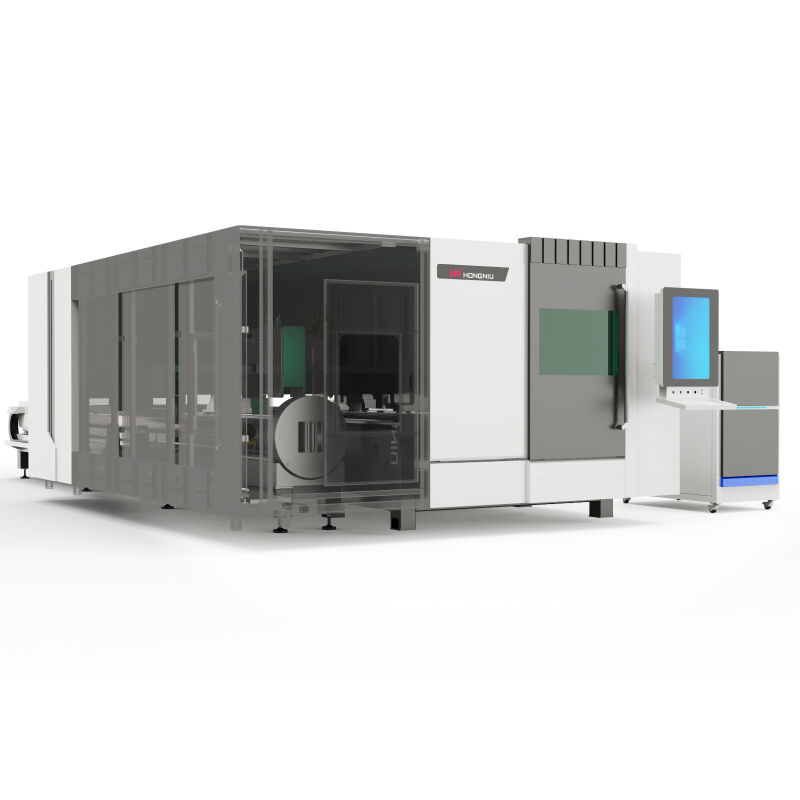

High-Quality Components for Reliable Performance

- Laser Source: Raycus (6–60kw) for stable and powerful cutting output.

- Laser Head: BOCI intelligent auto-focus head with anti-collision and smart monitoring.

- Gantry Beam: High-strength steel/aluminum beam with annealing & aging for accuracy.

- Servo Motors: High-inertia servo motors ensure smooth and dynamic movement.

- Cooling System: Intelligent chiller with over-temperature alarms.

- Electrical Components: OMRON / Schneider.

- Lubrication System: Fully automatic, programmable lubrication frequency.

- Dust Removal: Professional dust extraction system integrated inside the bed.

Specifications and Performance

The HN-LM oversize series supports 6–60kw power options and cuts up to 80 mm thickness.

The gantry double-drive system and heavy-duty frame guarantee long-travel accuracy and high-speed cutting at 150 m/min and 1.4G acceleration.

Ideal for heavy industry applications requiring both size and precision.

Applications and Versatility

Compatible Materials

-

Stainless Steel

-

Carbon Steel

-

Manganese Steel

-

Alloy Plates

-

Aluminum

-

Copper

-

Brass

- Galvanized Sheet

Industries

-

Engineering Machinery

-

Aerospace

-

Heavy Equipment Manufacturing

-

Metallurgy

-

Shipbuilding

-

Railway Components

-

Automotive Manufacturing

- Advertising & Metal Decoration

Applications:

- Long-format plate cutting (14m–26m)

- Heavy machinery structural parts fabrication

- Aerospace & rail transit components

- Large-format industrial metal sheets

- Precision cutting with smoke-free environment

- High-power thick plate cutting up to 80mm

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Gantry-type oversize format – supports extremely long sheet processing.

- Smoke-free bedding design – top-level clean cutting environment.

- Double light curtain protection – full safety coverage.

- Customizable large-format platform – 14m / 26m optional.

- Exclusive patented cross-support bed structure – highest stability.

- Frame rail assembly – reduces shipment cost.

- Independent nail bed – retains long-term accuracy during high-temperature work.

- High-speed performance – 150 m/min and 1.4G.

- Premium components – Raycus laser, BOCI head, OMRON electrics.

- Automatic lubrication & professional dust removal system.

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Fiber Laser Cutting Machine

- Gantry Type Large Format Laser Cutter

- High-Power CNC Laser Machine

- Industrial Metal Cutting