Specifications:

| Model |

HN-1500JXS |

| Arm Span |

1.4–2.0 m |

| Axes |

6 Axis |

| Laser Power |

1500W - 3000W |

| Central Wavelength |

1080 nm |

| Re-positioning Accuracy |

±0.1 mm |

| Cutting Speed |

20 m/min |

| Cooling System |

Water Chiller |

| Programming Mode |

Teach Pendant |

| Laser Source |

Raycus / Max / RECI |

| Control System |

FSCUT |

| Laser Head |

BOCI / RAYTOOLS |

| Electrical Components |

Schneider |

| Power Supply |

380V / 50HZ |

| Machine Weight |

150 kg |

Description:

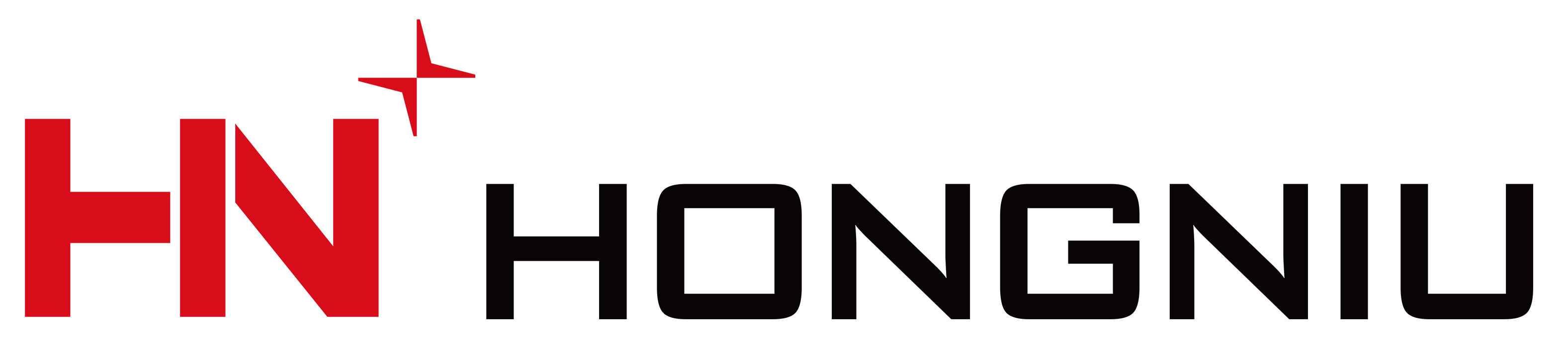

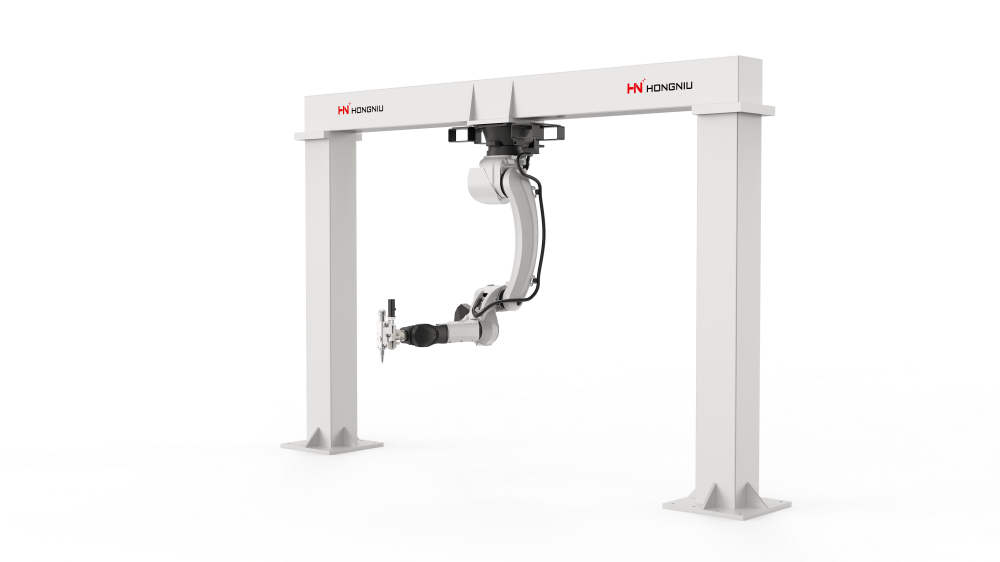

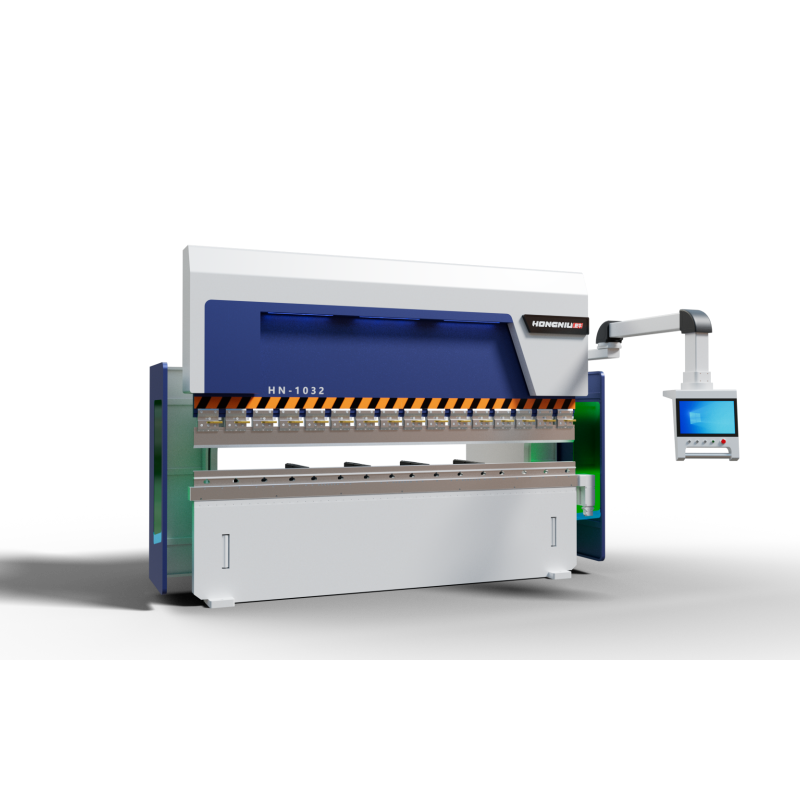

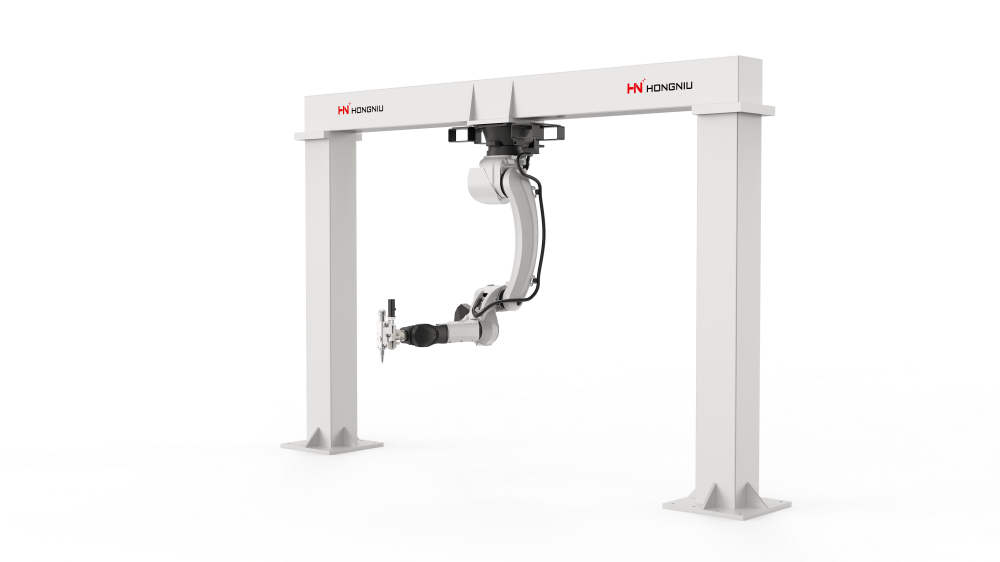

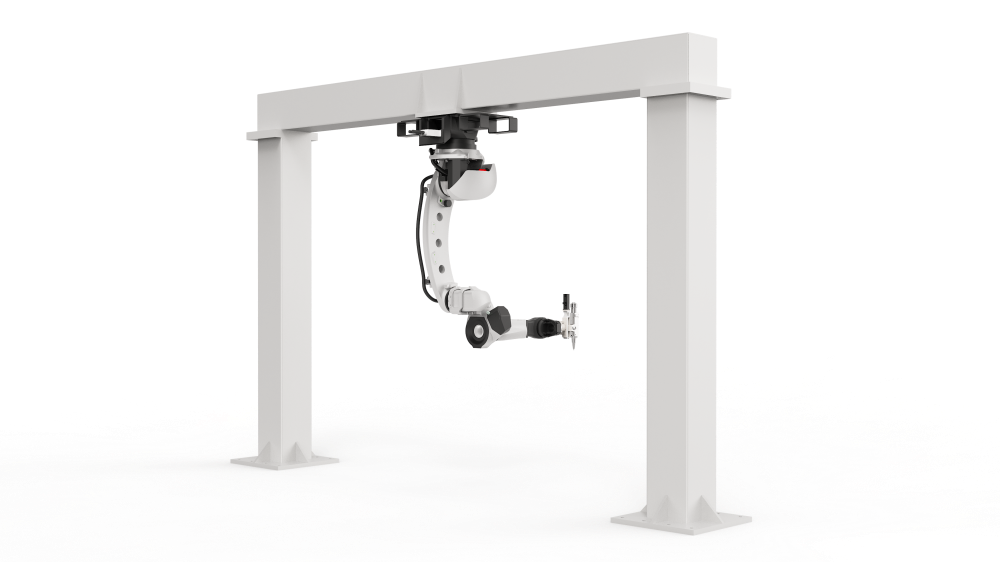

3D Laser Cutting Robot is an advanced robotic fiber laser system designed for high-precision three-dimensional cutting applications. By combining a high-performance fiber laser source with a six-axis industrial robotic arm, the system enables flexible cutting of complex curves, bevels, and irregular geometries in three-dimensional space.

This solution significantly reduces processing time while improving cutting accuracy, automation level, and production efficiency.

High-Quality Components for Reliable Performance

- Robotic Arm: Six-axis linkage for full spatial freedom

- Laser Source: Raycus / Max / RECI fiber laser generators

- Laser Head: BOCI / RAYTOOLS for stable and efficient cutting

- Control System: FSCUT CNC control system

- Servo Motors & Drives: DELTA / Fuji / Yaskawa

- Electrical Components: Schneider industrial-grade components

- Cooling System: Independent water chiller for laser and optics protection

Specifications and Performance

The system supports laser power from 500W to 3000W, capable of cutting carbon steel up to 16 mm, delivering smooth edges and high dimensional accuracy. The ±0.1 mm repositioning accuracy ensures stable and repeatable cutting quality, even for complex 3D contours.

Teach pendant programming allows fast setup and intuitive operation, making it suitable for both automated and semi-automated production environments.

Applications and Versatility

Applicable Materials:

-

Carbon Steel

-

Stainless Steel

-

Aluminum

-

Copper

-

Brass

- Galvanized Tube

Processing Capabilities:

- 3D curve cuttin

-

Irregular and complex geometries

-

Bevel cutting and edge trimming

-

Sheet metal and tubular components

- Multi-angle and spatial cutting tasks

Applications:

- Automotive parts and structural components

- Sheet metal fabrication

- Hardware and metal fittings

- Engineering machinery

- Aerospace components

- Metal furniture and decorative parts

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Six-Axis Robotic System: Full spatial freedom for complex 3D cutting

- High Flexibility: Multiple arm span options up to 2.0 m

- High Precision: ±0.1 mm repositioning accuracy

- Efficient Programming: Teach pendant operation, easy learning curve

- Stable Cutting Performance: High-quality laser source and optics

- Automation Ready: Easily integrated into automated production lines

- Compact Design: Small footprint with powerful processing capability

- Low Maintenance: Non-contact laser cutting reduces tool wear

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- 3D Laser Cutting Robot

- Six Axis Laser Cutting System

- Robotic Fiber Laser Cutting Machine

- Industrial Laser Cutting Robot

-

Automated 3D Metal Laser Cutting