Specifications:

| Model |

14032FA |

| Working Area |

14000 × 3200 mm - 26000 × 3200 mm |

| Laser Power |

12kw – 40kw |

| Laser Source |

Raycus / Max / RECI / IPG |

| Laser Head |

BOCI / RAYTOOLS |

| Motor & Drivers |

DELTA / Fuji / Yaskawa |

| Control System |

FSCUT |

| Positioning Accuracy |

±0.15 mm |

| Re-positioning Accuracy |

±0.15 mm |

| Cutting Speed |

80 m/min |

| Cutting Thickness |

0–90 mm |

| Cooling Method |

Water cooling |

| Power Supply |

380V 3P 50HZ |

| Gross Weight |

23,000 kg |

Description:

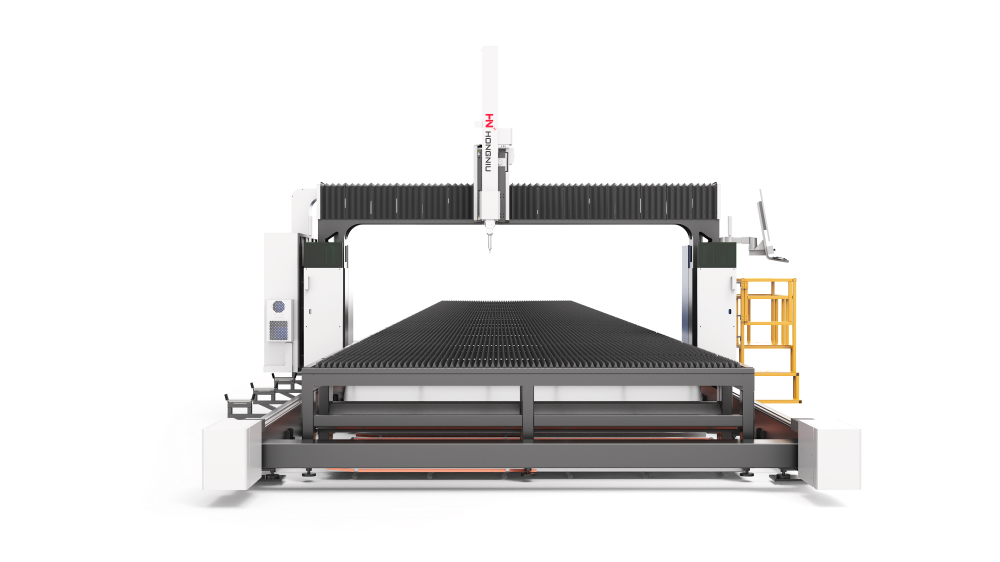

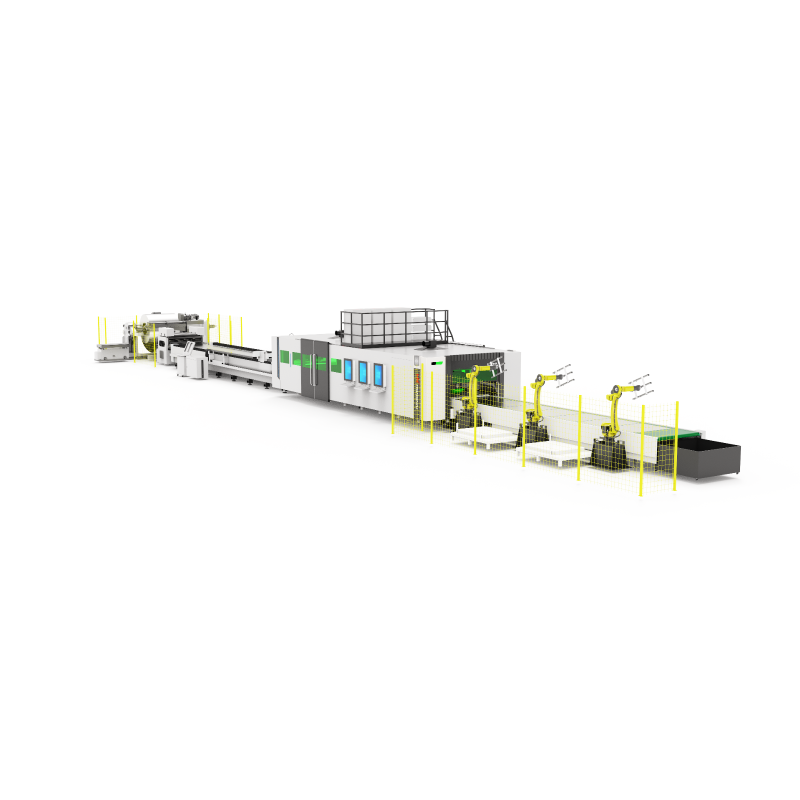

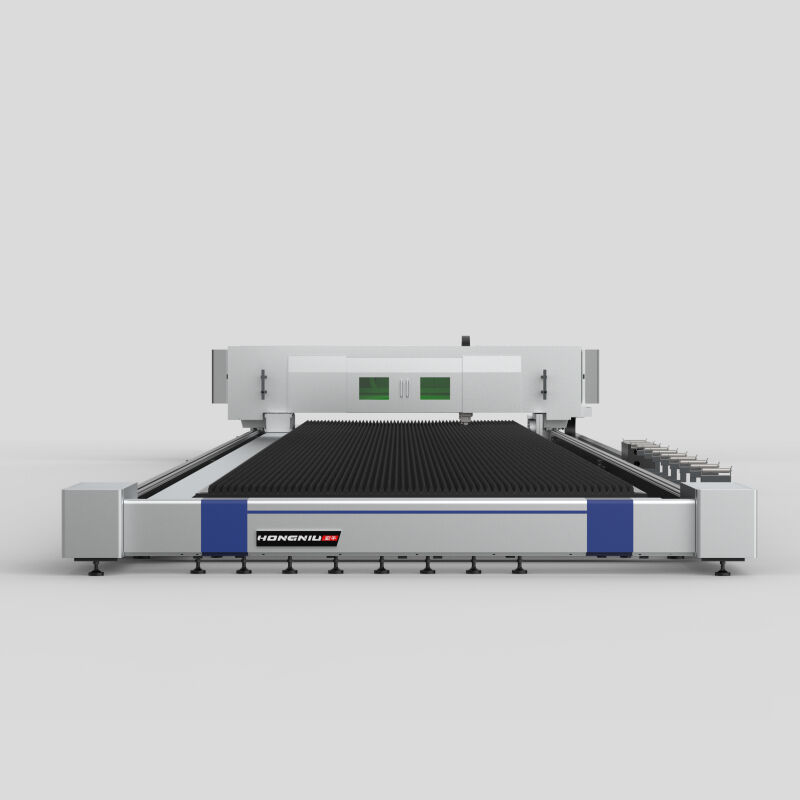

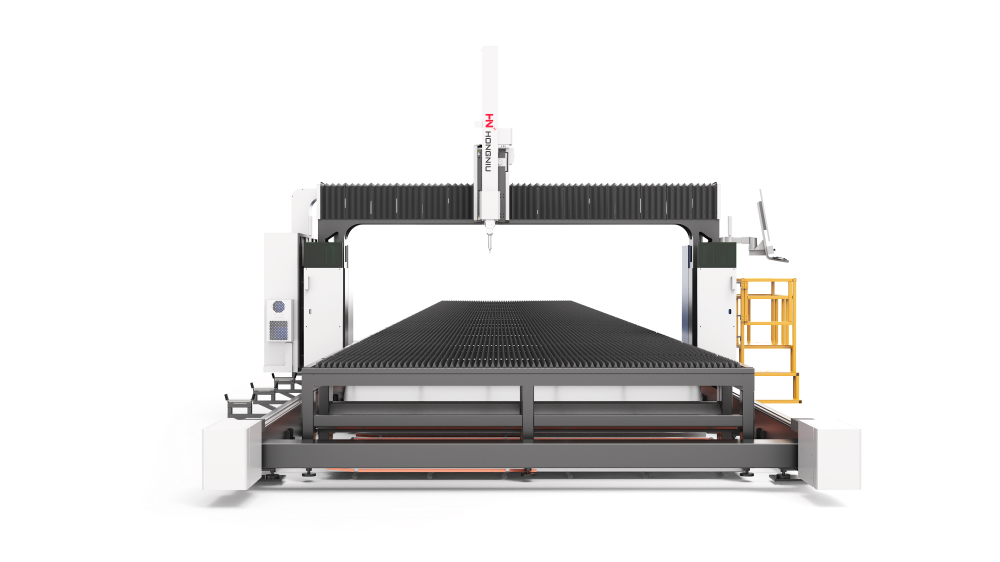

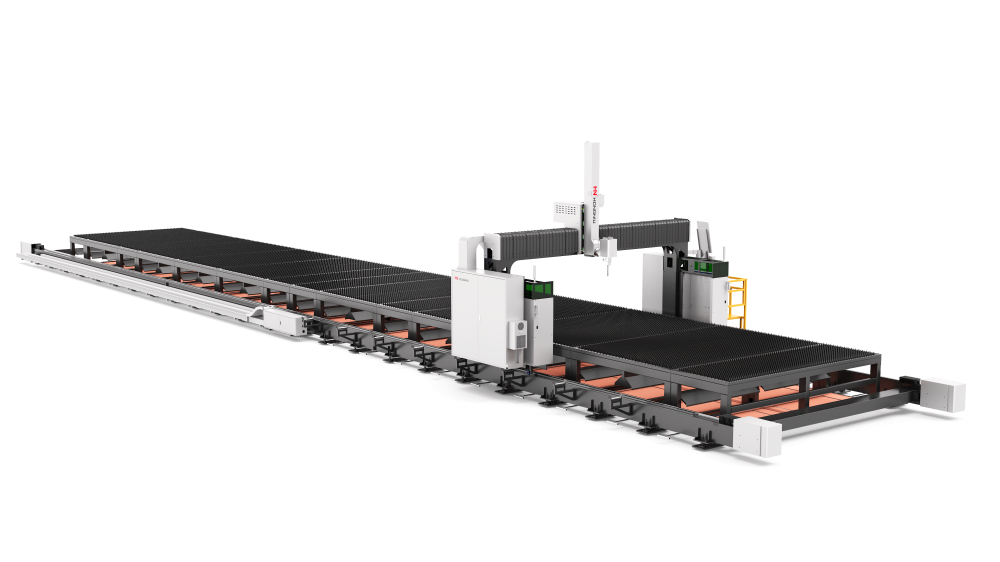

The Three-Dimensional Five-Axis Fiber Laser Cutting Machine is a high-end CNC system designed for complex section steel processing. It integrates fiber laser cutting, precision mechanics, intelligent detection, and three-dimensional five-axis CNC technology.

This machine enables chuck-free cutting of large steel sections, ensuring fast processing speed, excellent forming accuracy, and a high one-time through-hole rate. It supports multi-process operations including cutting, hole opening, beveling, marking, locking ports, and welding holes in a single setup.

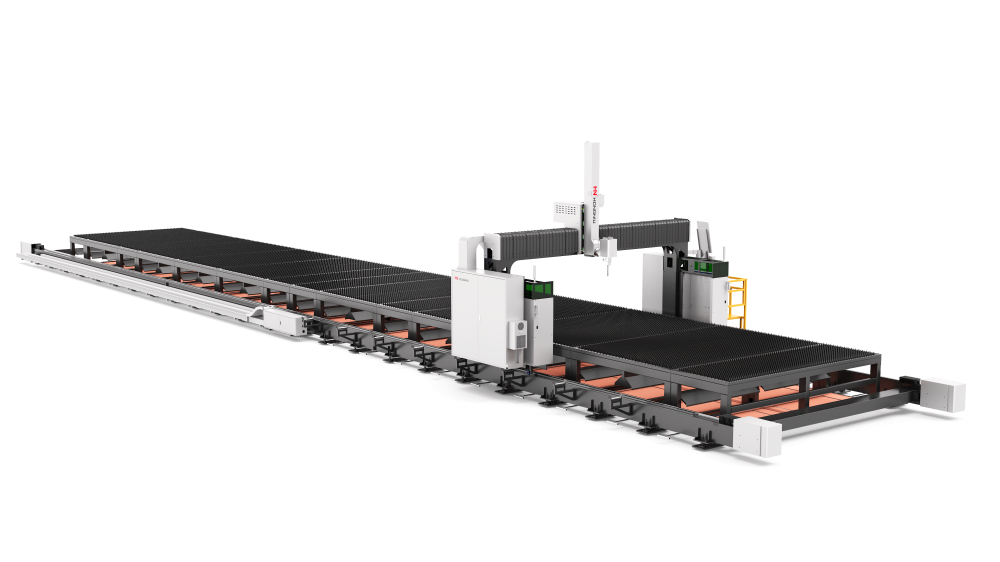

With optional dual-station design, loading and unloading time is significantly reduced, improving overall production efficiency and lowering labor costs.

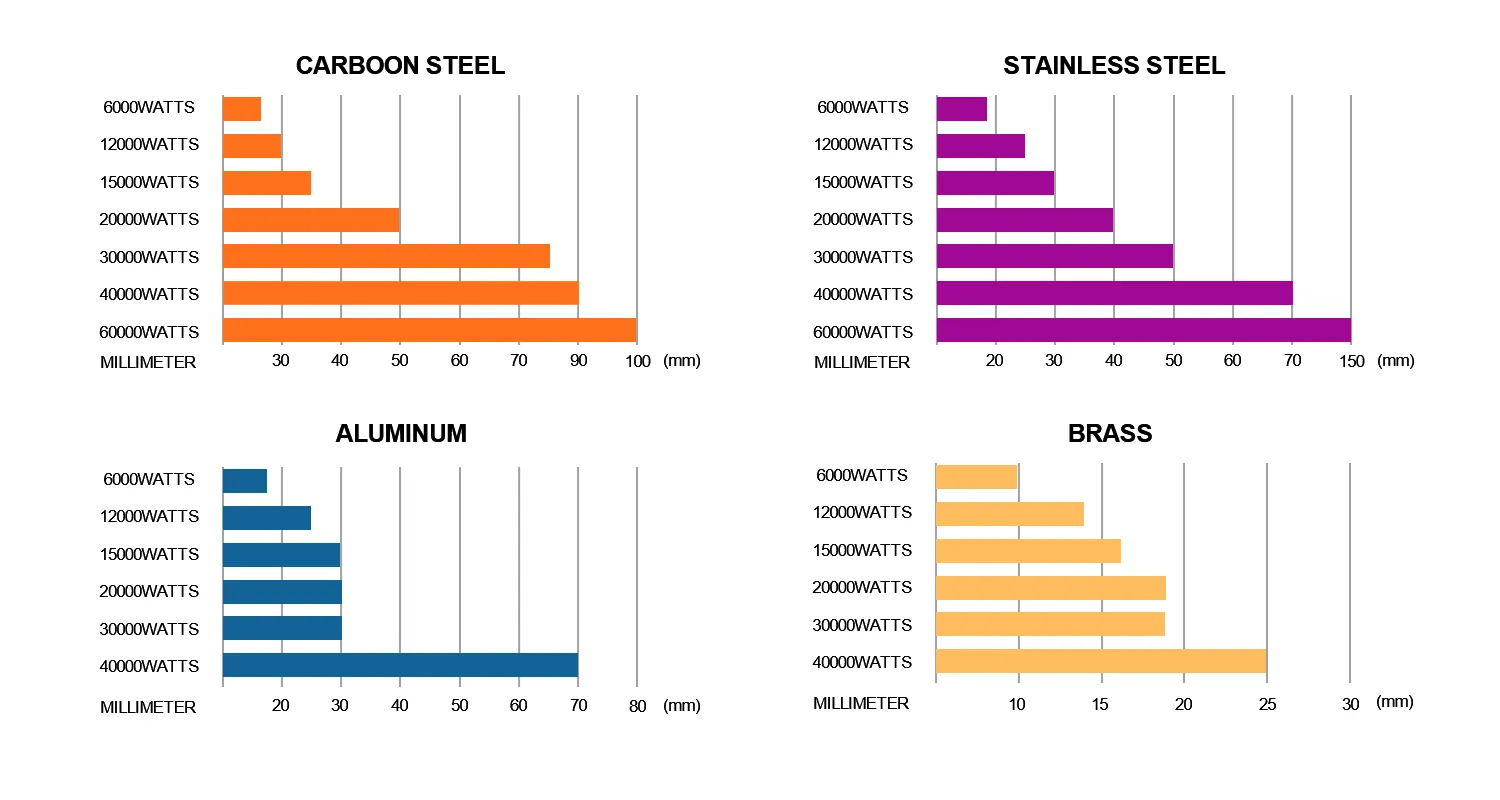

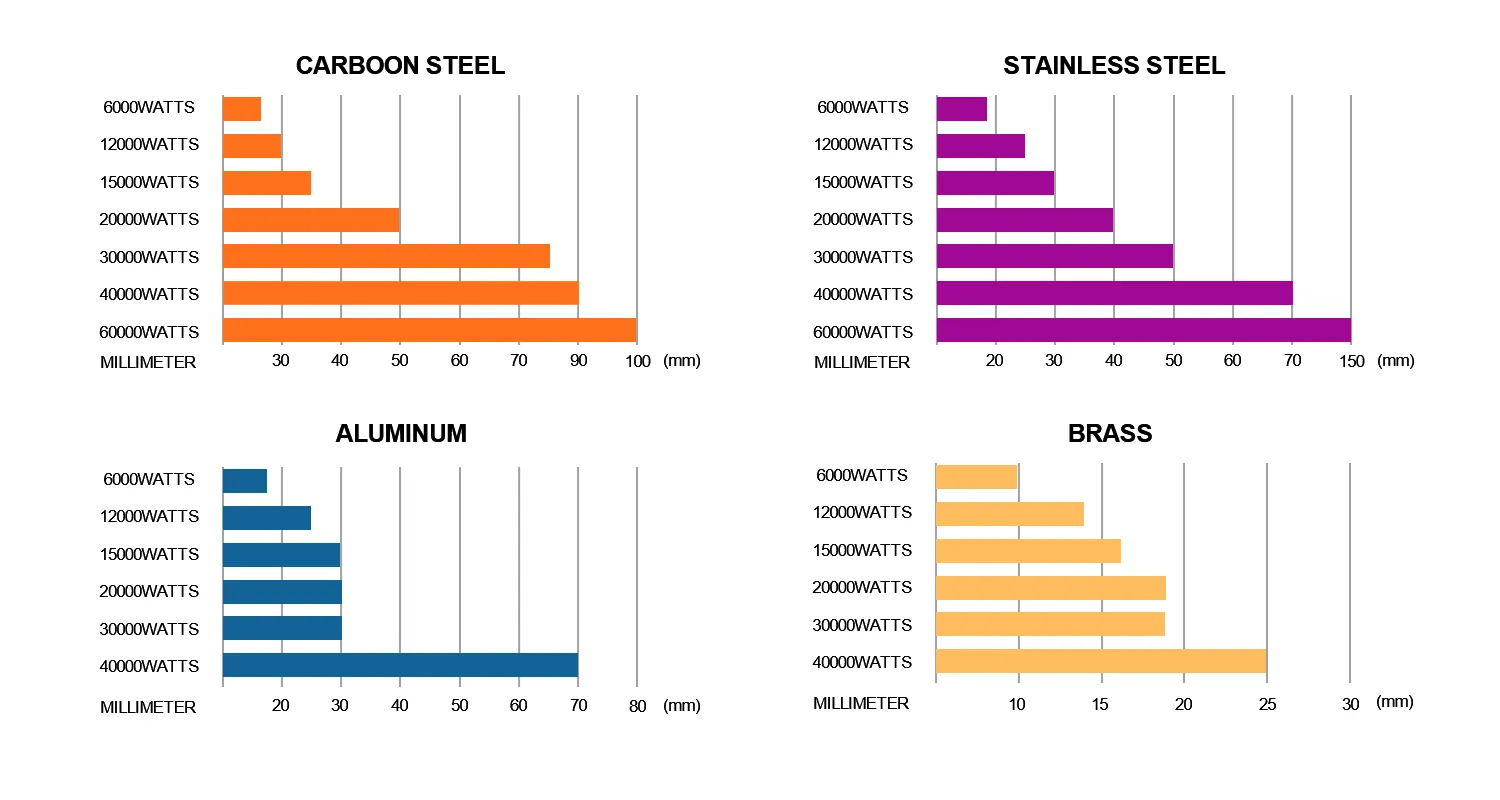

Cutting Parameters:

Cutting Samples:

High-Quality Components for Reliable Performance

- Laser Source: Raycus, Max, RECI, or IPG for stable high-power output

- Laser Head: BOCI / RAYTOOLS with auto-focusing, anti-collision protection, and intelligent monitoring

- Motors & Drivers: DELTA, Fuji, or Yaskawa for high-speed, high-precision motion control

- Electrical Components: Schneider and Omron for long-term reliability and safety

- Control System: FSCUT five-axis CNC system supporting CAD/DXF, layout optimization, and flying cuts

- Cooling System: Industrial water chiller with over-temperature alarm

- Automatic Lubrication: Programmable lubrication frequency and volume for extended service life

Specifications and Performance

The FA series offers extra-large working areas up to 26000 × 3200 mm with laser power up to 40kw, capable of cutting steel thicknesses up to 90 mm.

Advanced five-axis linkage allows precise spatial cutting of complex section steels. Gantry double-drive transmission, aviation-grade beam structure, and high-speed servo motors ensure excellent rigidity, dynamic performance, and long-term accuracy.

Applications and Versatility

Applicable Materials:

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Galvanized Steel

- Aluminum and Other Metal Sections

Applicable Profiles:

- H-beams, I-beams

- Channel steel, angle steel

- T-shaped steel

- Rectangular and special-shaped tubes

Applications:

- Three-dimensional cutting of large steel sections

- One-time processing of holes, bevels, and connection nodes

- Fabrication of structural components for heavy industries

- Integrated cutting of profiles, plates, and tubes

- High-precision machining for complex spatial structures

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Five-Axis 3D Cutting: Enables complex spatial cutting with high precision

- Chuck-Free Processing: Ideal for large and irregular section steels

- Four-in-One Capability: Profiles, plates, tubes, and bevels in one machine

- High Accuracy Forming: Shape error controlled within 0.2–0.5 mm

- Optional Dual Station: Reduced downtime and higher productivity

- Wide Power Range: 12kw–40kw for heavy-duty applications

- Heavy-Duty Structure: Honeycomb carbon bed with stress relief treatment

- Premium Components: IPG/Raycus lasers, BOCI/RAYTOOLS heads, FSCUT CNC, Schneider electronics

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Five Axis Fiber Laser Cutting Machine

- 3D Section Steel Laser Cutter

- Heavy Duty Profile Laser Cutting

- Three Dimensional CNC Laser Machine

-

High Power Fiber Laser Cutting System