Core Specifications:

| Model |

3015L |

| Working Area |

3000×1500 mm-6000×1500 mm |

| Laser Power |

1.5KW – 6KW |

| Laser Source |

Raycus / Max / RECI / IPG |

| Motor and Drivers |

DELTA / Fuji / Yaskawa |

| Laser Head |

BOCI / RAYTOOLS |

| Electrical Components |

Schneider |

| Electronically Proportional Valve |

Japan SMC / Germany Lanny |

| Reducer, Rack & Rail |

Hongniu |

| Control System |

FSCUT |

| Power Supply |

10.5KW – 28KW |

| Gross Weight |

2000 kg |

| Machine Size |

4498 × 1913 × 1480 mm |

Description:

|

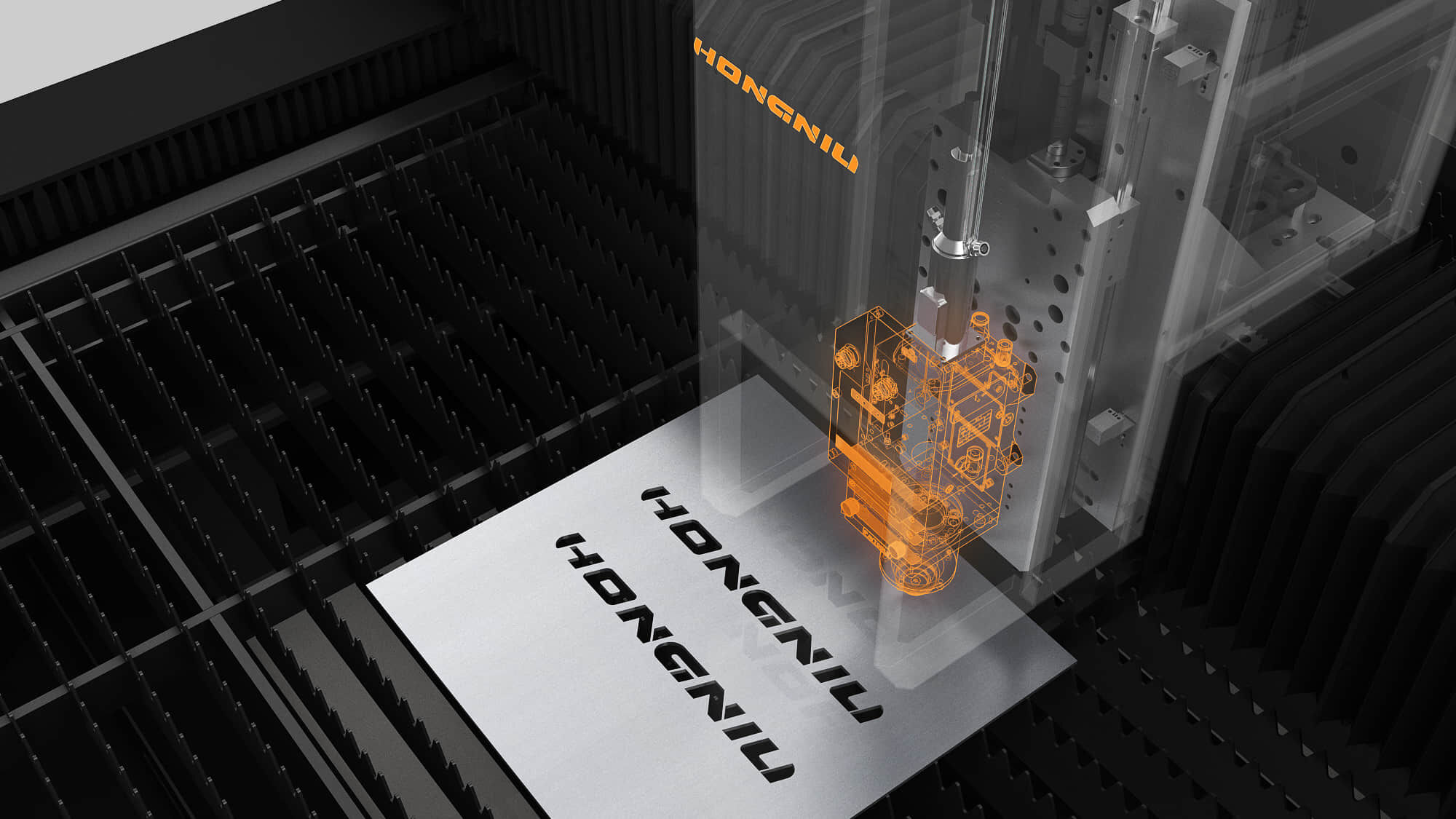

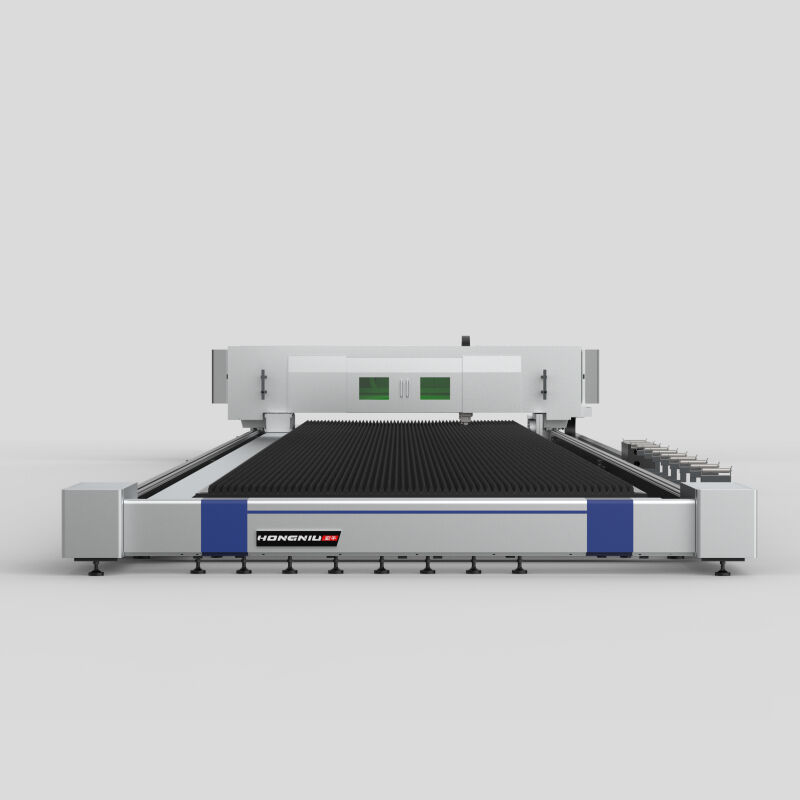

Single Platform Fiber Laser Cutting Machine – Model 3015L

The 3015L Single Platform Fiber Laser Cutting Machine is a cost-effective, high-performance solution designed for precision metal cutting across diverse industrial applications. Engineered with both efficiency and durability in mind, this machine combines advanced design, robust components, and user-friendly operation to deliver exceptional cutting results while maintaining a competitive price point.

|

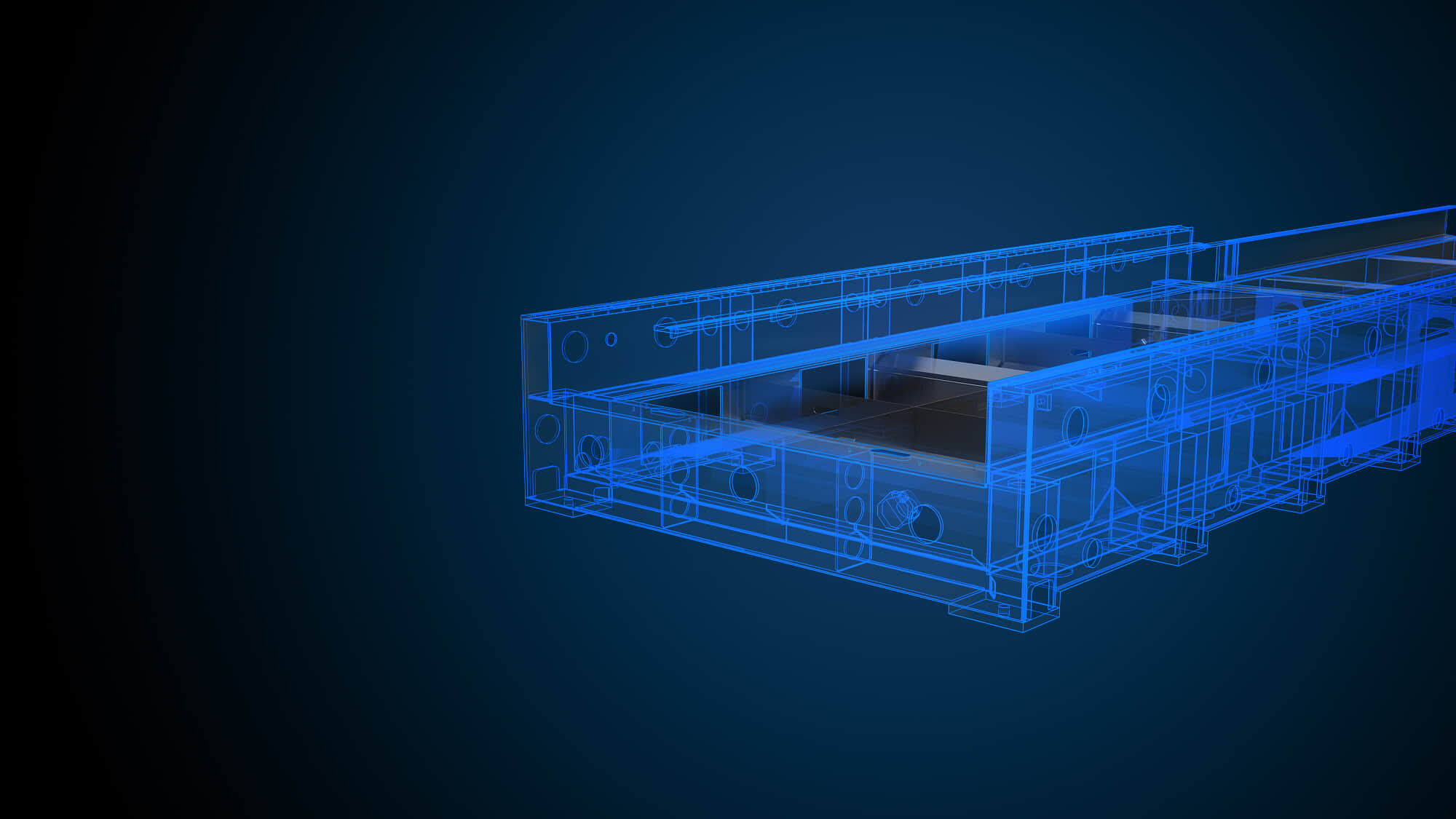

Lightweight Yet Stable Structure

Featuring an aviation aluminum profile crossbeam and a scientifically optimized bed structure, the 3015L achieves an ideal balance between lightweight design and mechanical stability. This ensures precise operation without compromising structural integrity, allowing the machine to maintain long-term reliability even under heavy-duty use. Its middle-through type dust removal flue, combined with a dedicated fan system, efficiently extracts dust and debris during cutting, maintaining a clean working environment and prolonging machine lifespan.

|

|

|

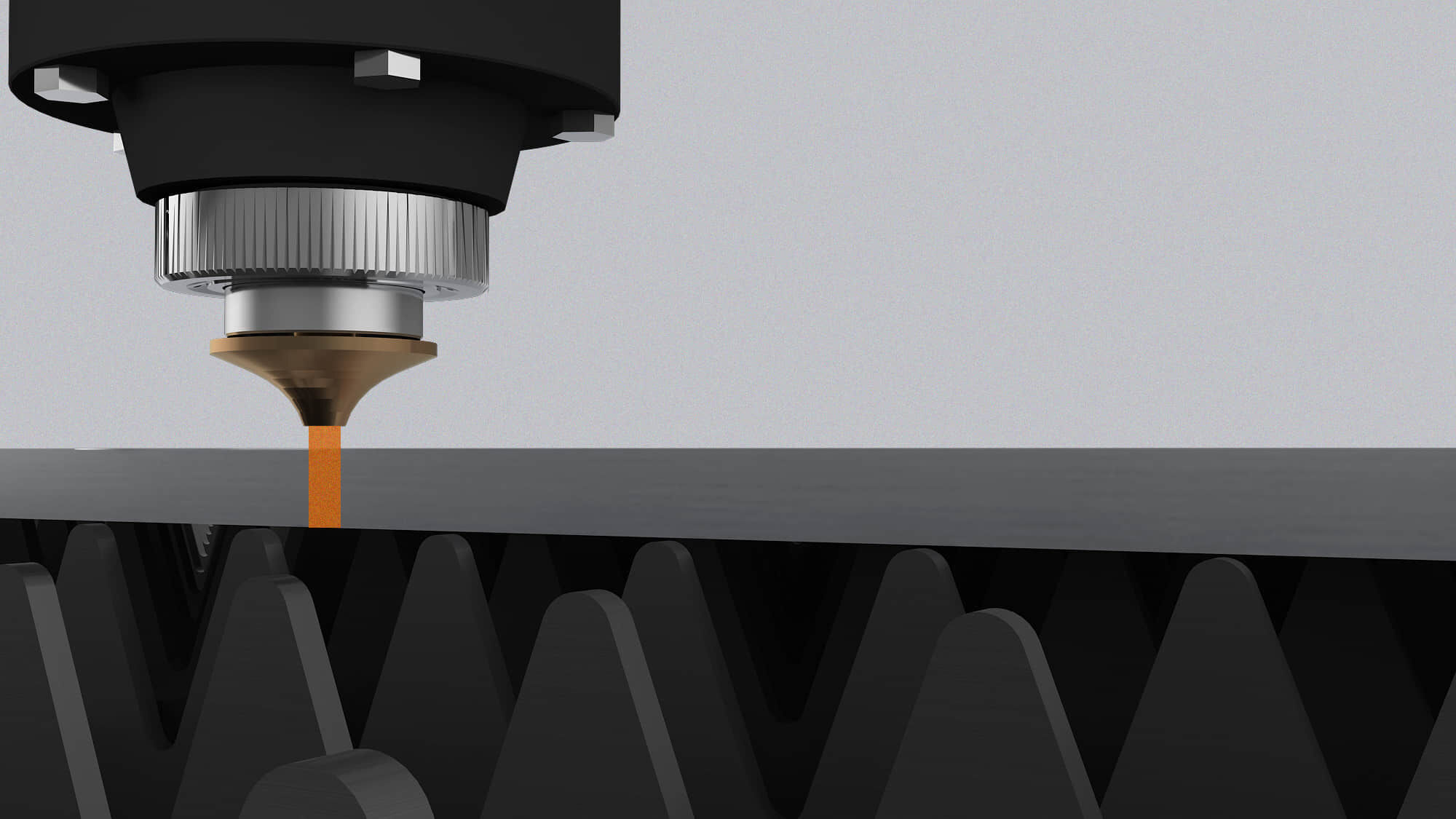

Precision Motion and Smooth Operation

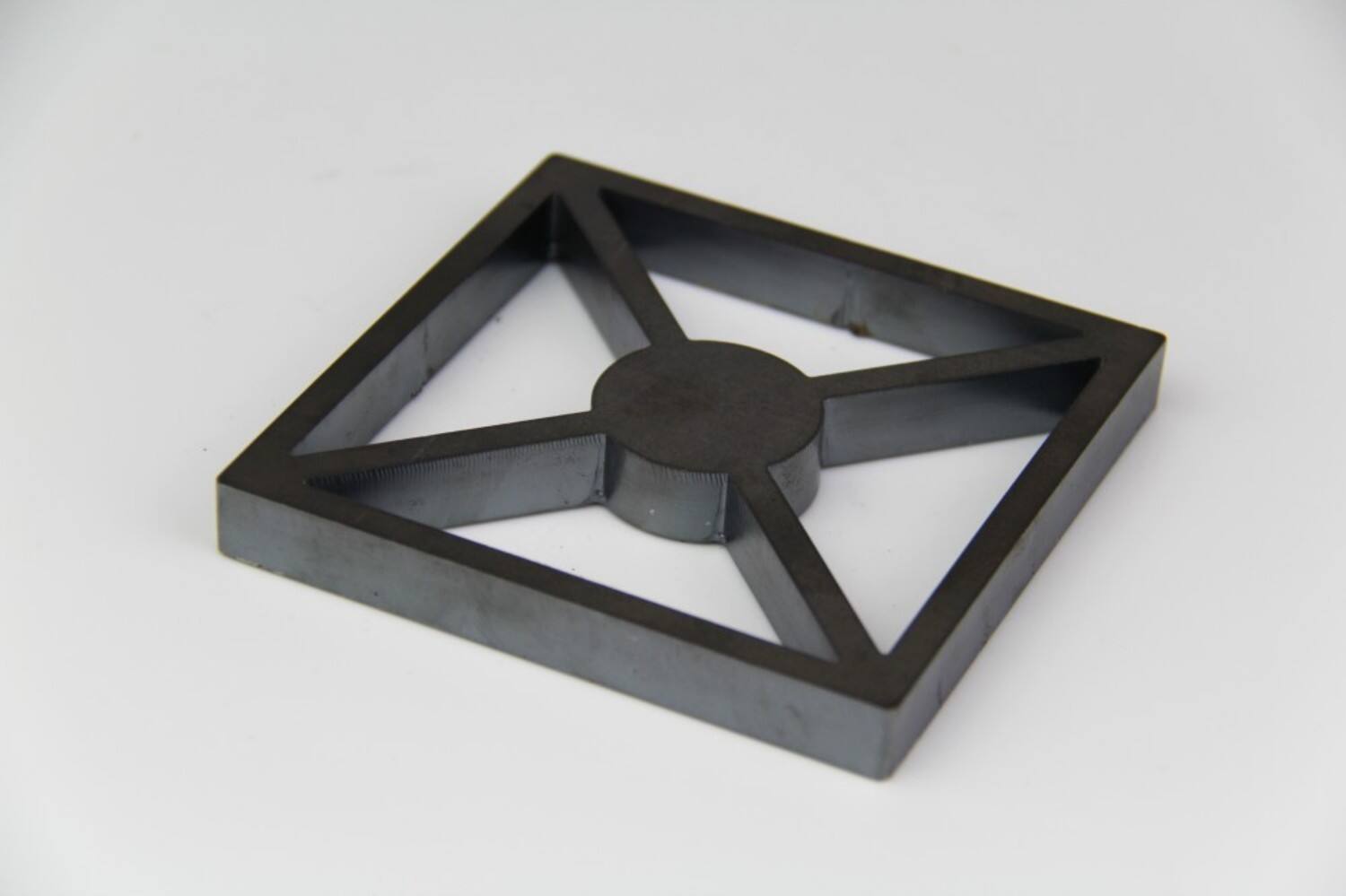

The 3015L is equipped with standard shaft output gear transmission and dual-axis precision linear guides on both X and Y axes. These advanced components guarantee smooth, stable operation, high cutting accuracy, and repeatable performance for complex designs. The optimized blade structure, complemented by an innovative blade pressing plate, ensures consistent material handling during the picking process, eliminating the risk of material adhesion and enabling reliable blade pickup every time.

|

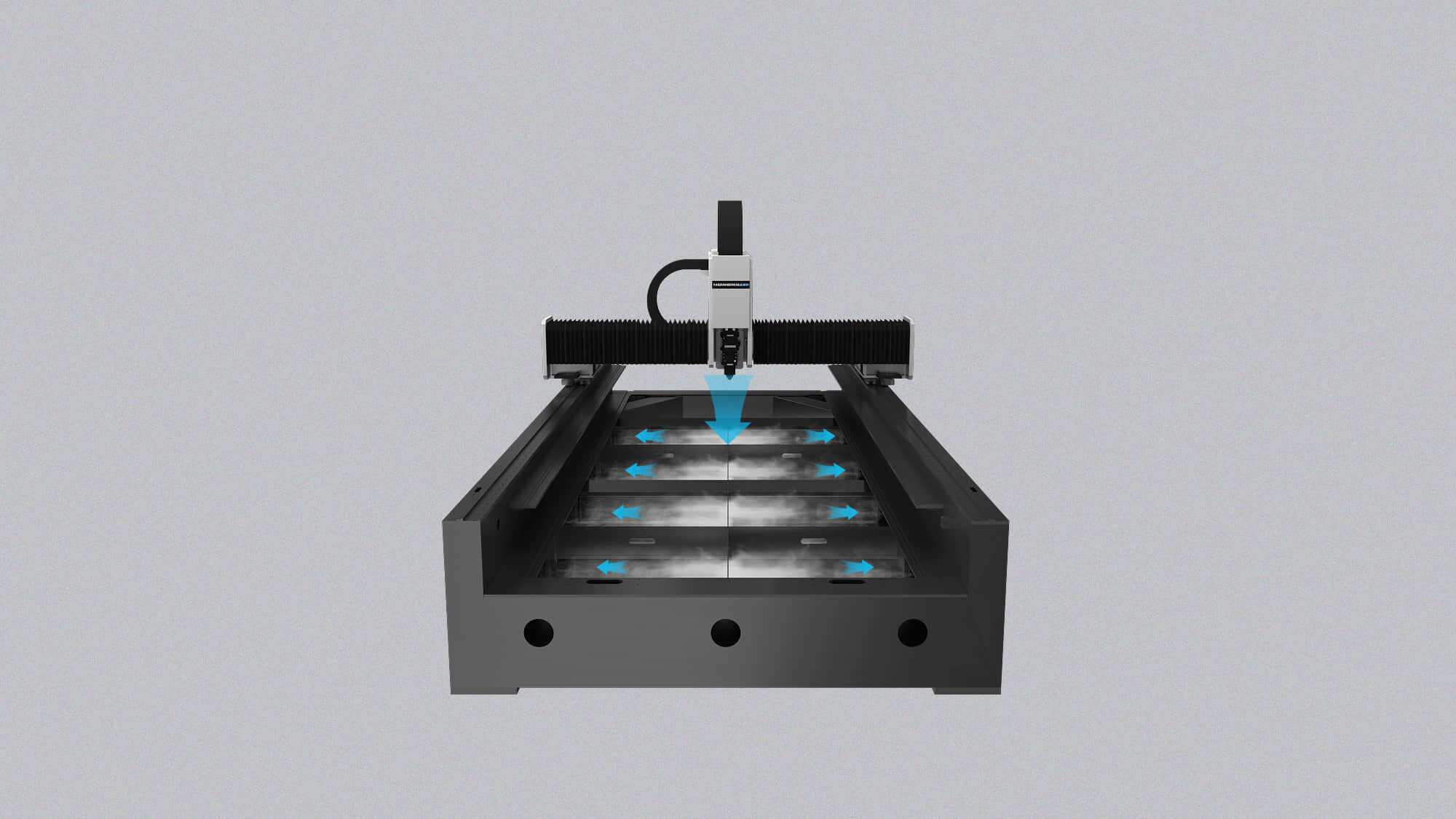

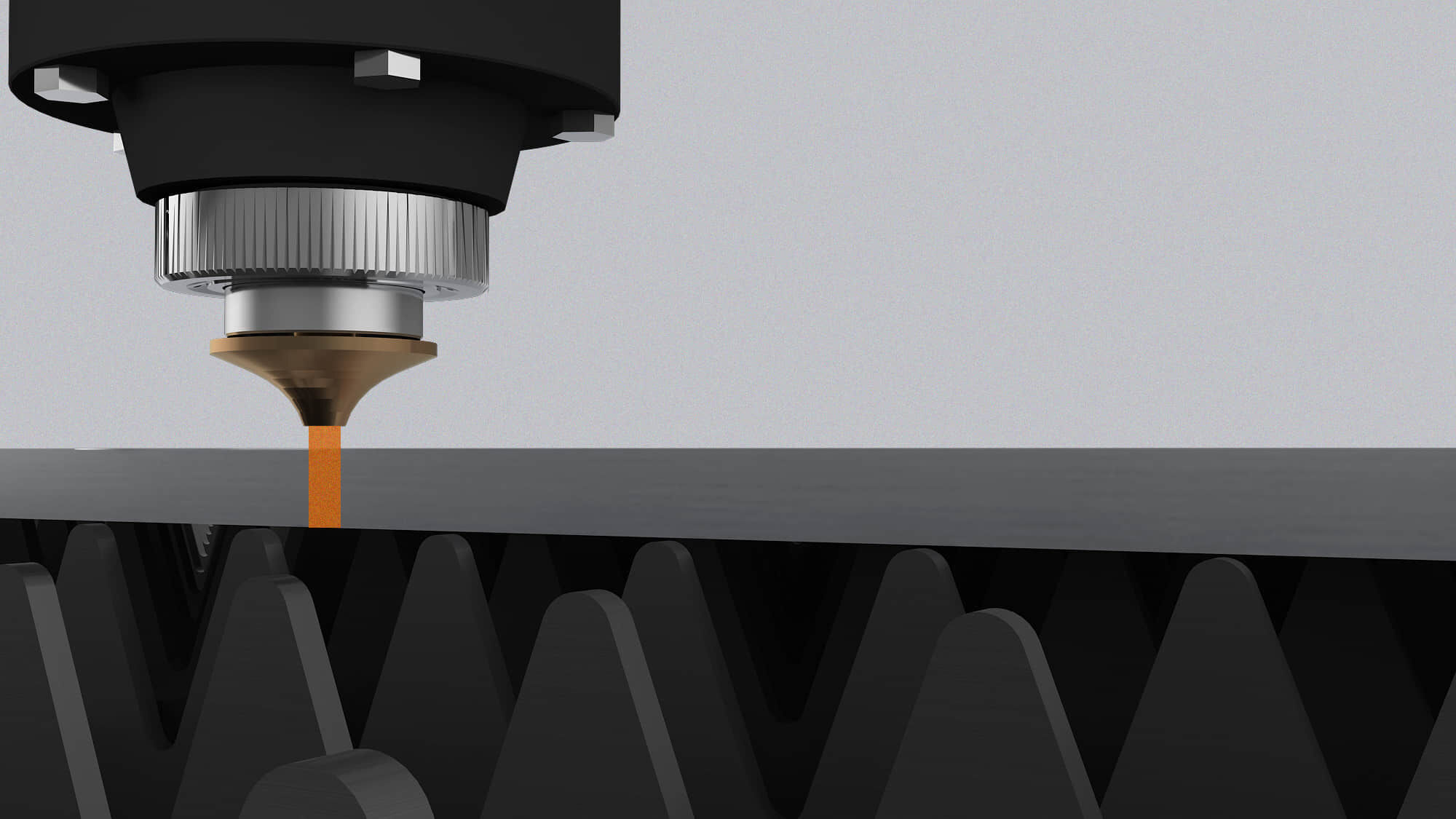

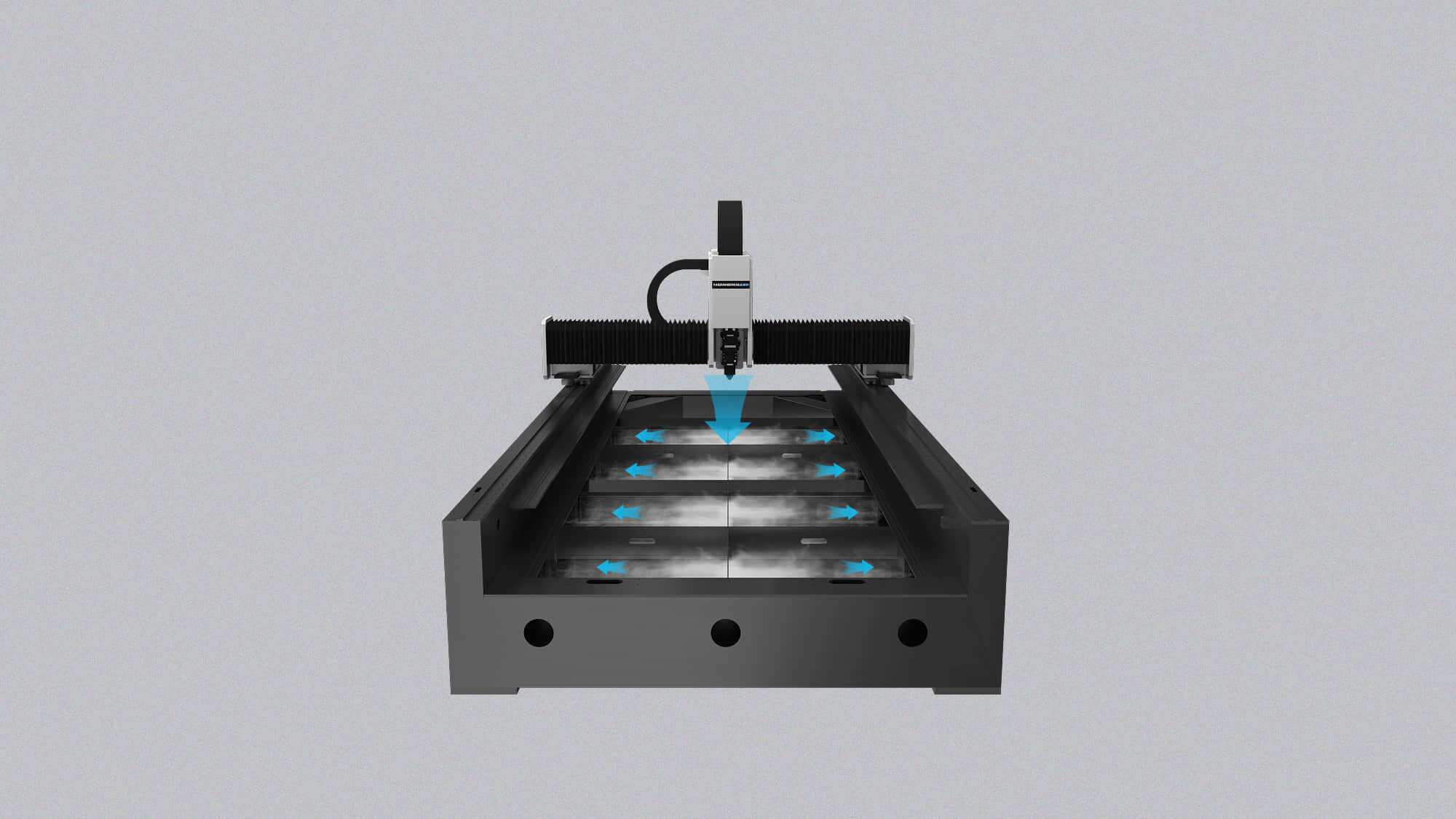

Efficient Dust Removal System

The 3015L features a middle-through dust removal flue designed for effective fume and debris extraction. The airflow is guided smoothly through the central duct and removed by a high-efficiency fan, keeping the cutting area clean and visible. This system prevents heat buildup and protects key optical components from contamination. Its streamlined design ensures stable suction, lower maintenance, and a cleaner working environment, making it ideal for continuous industrial production.

|

|

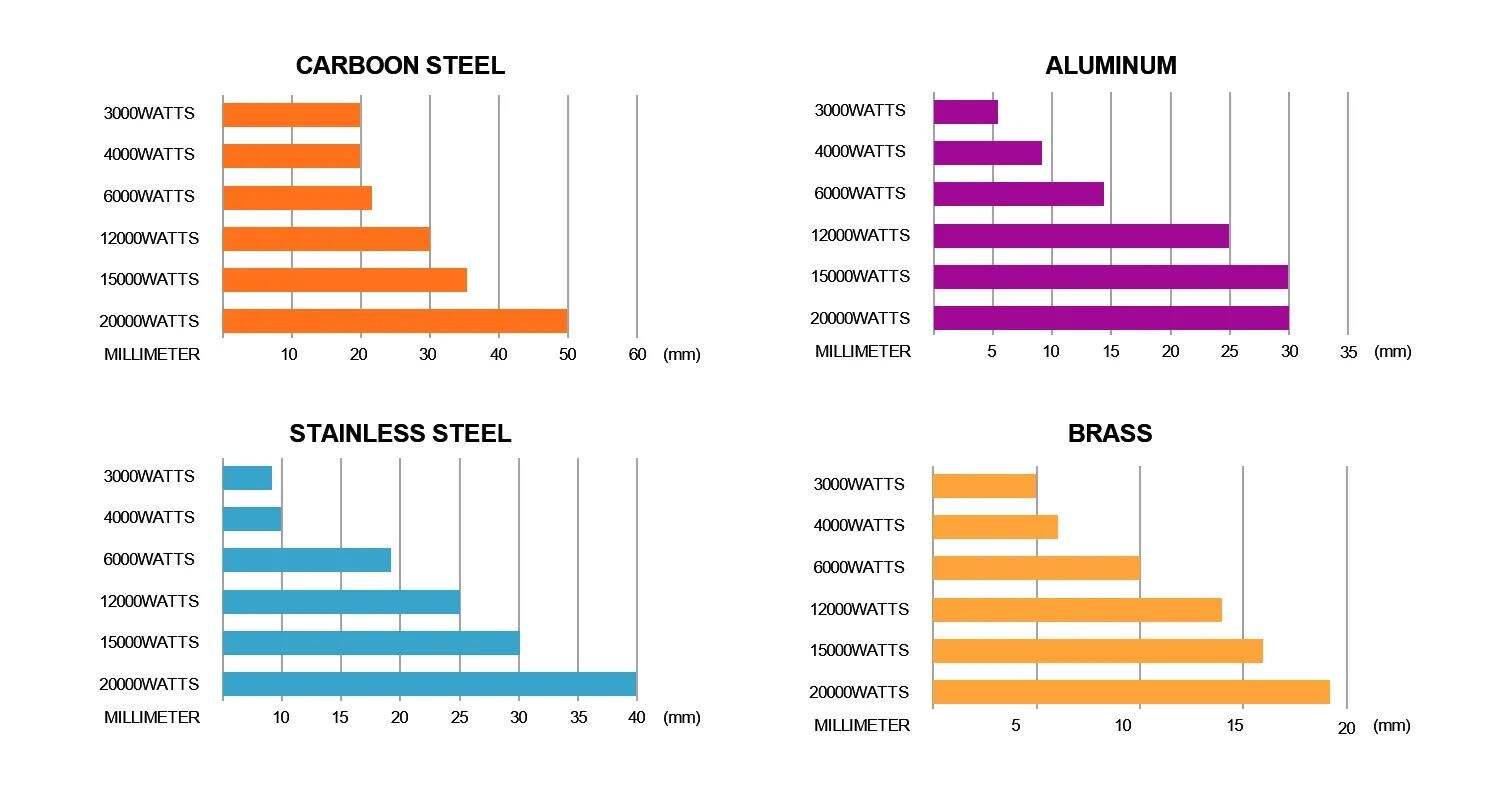

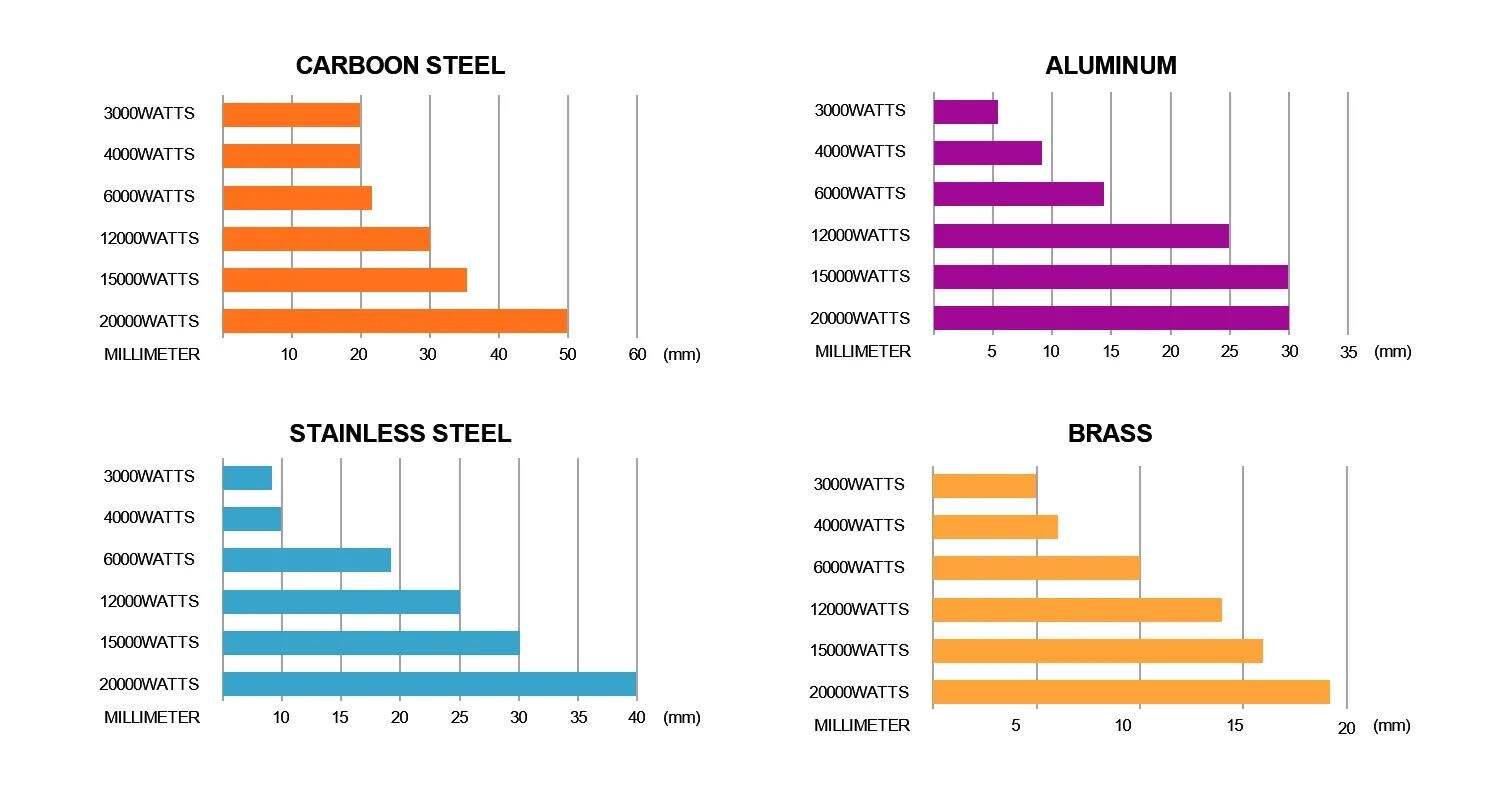

Cutting Parameters:

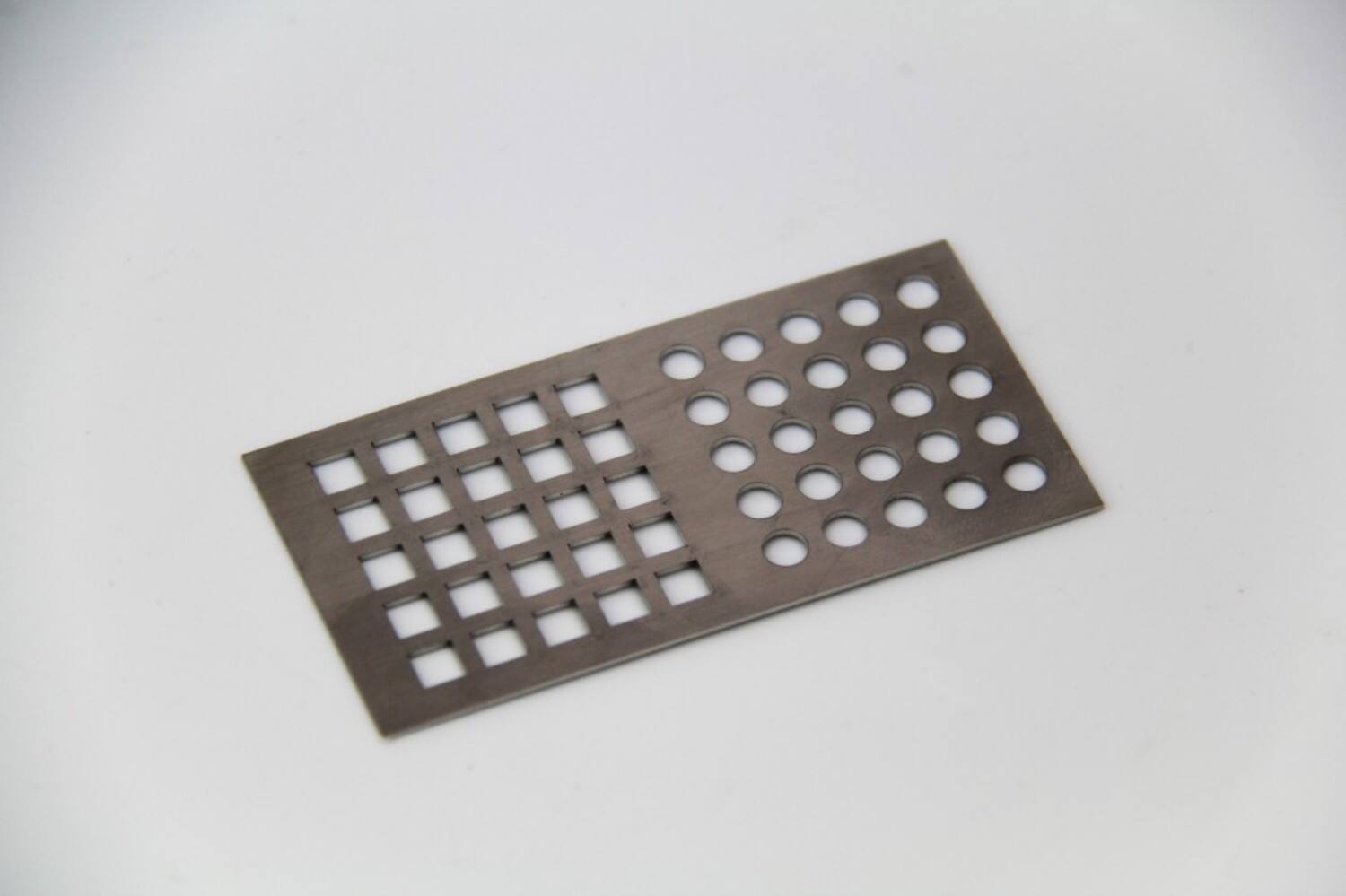

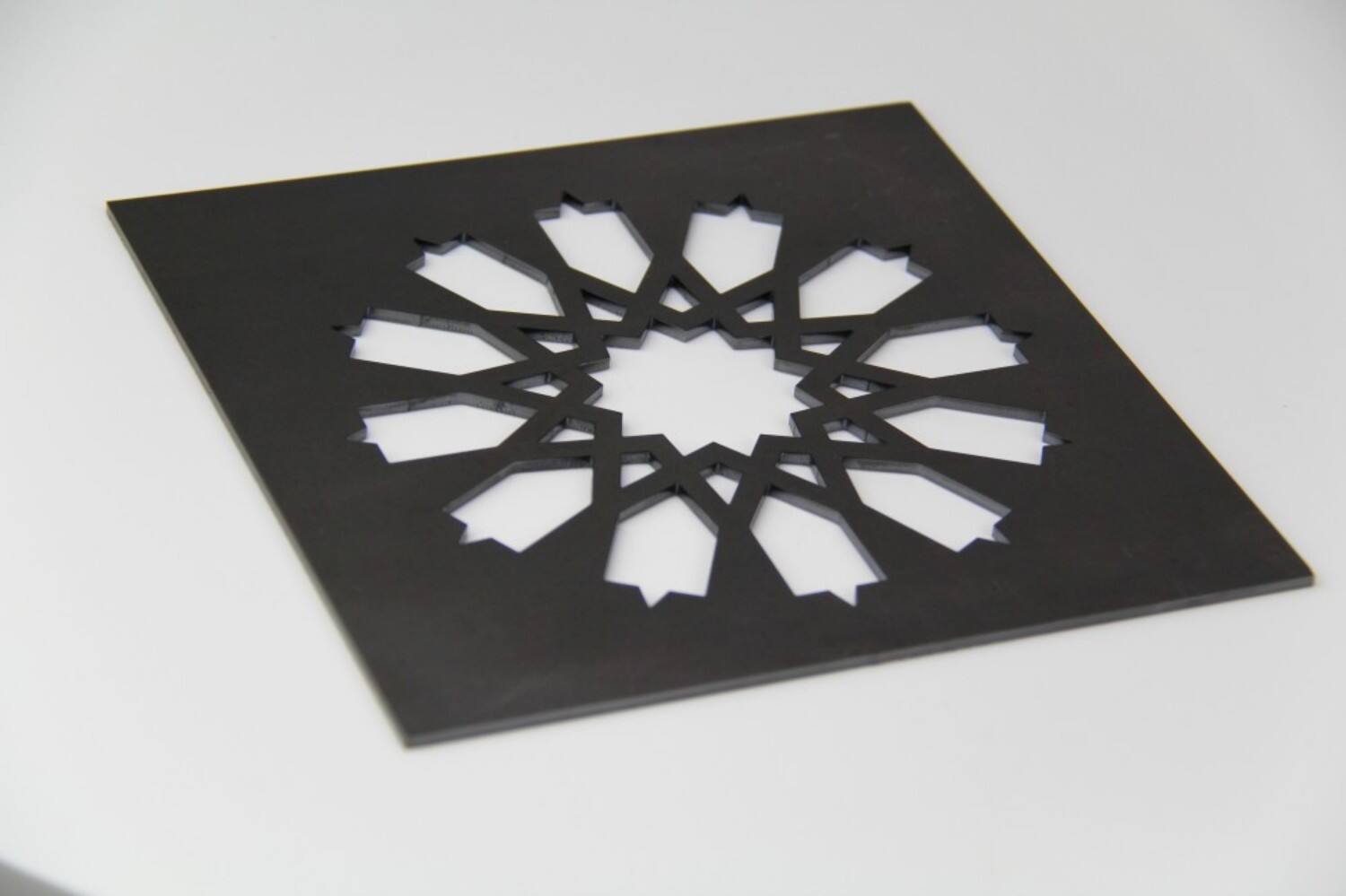

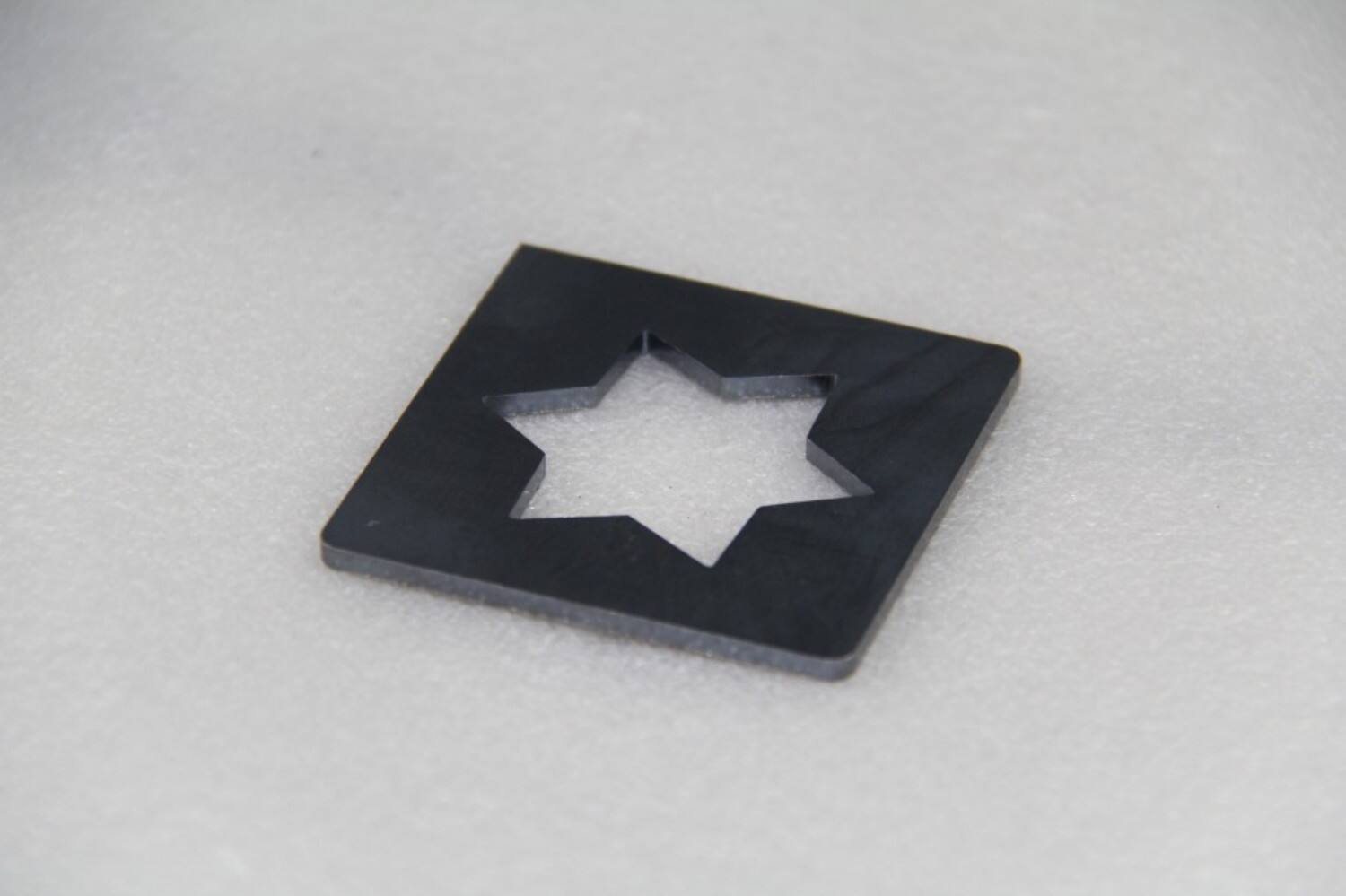

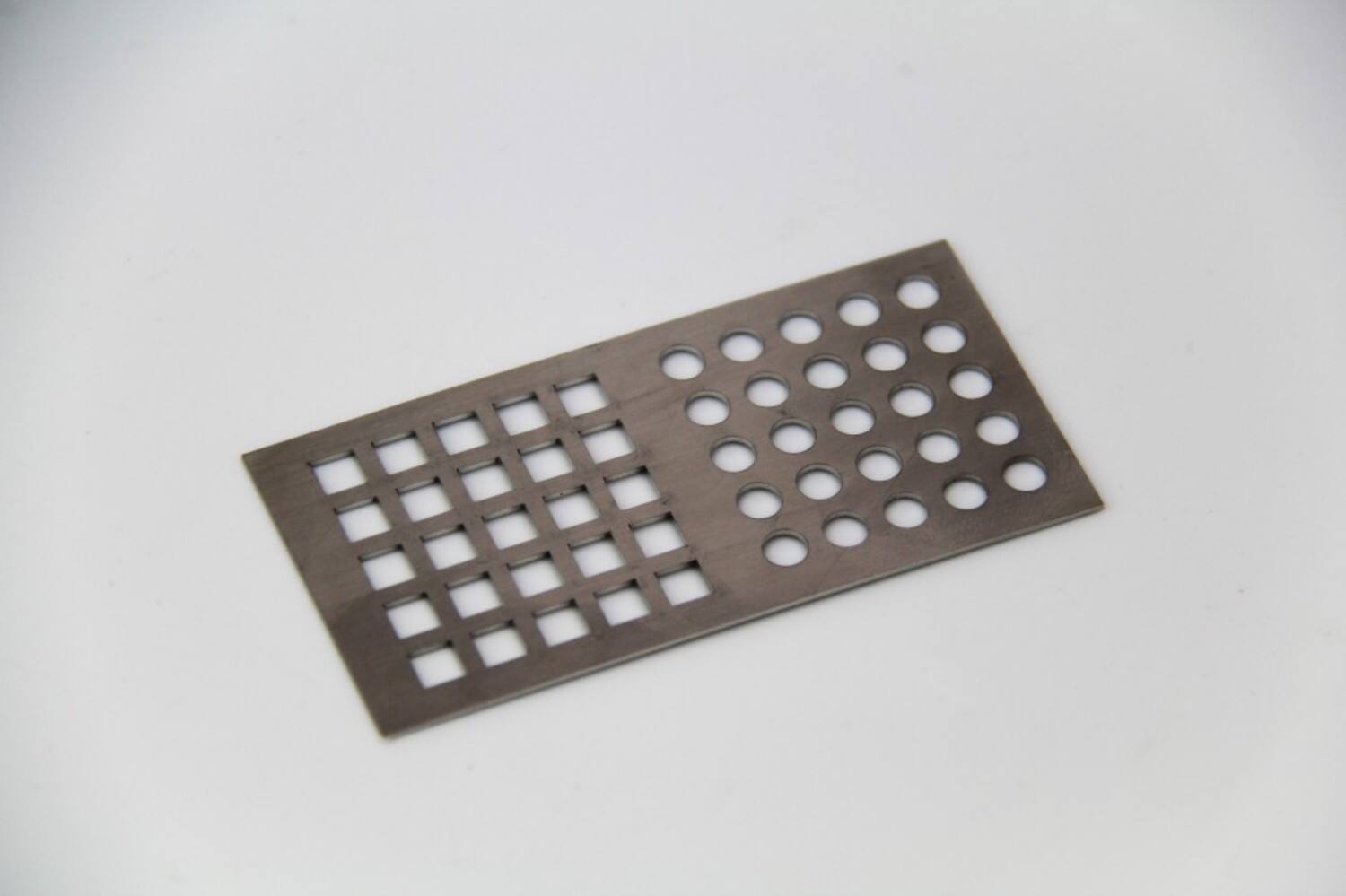

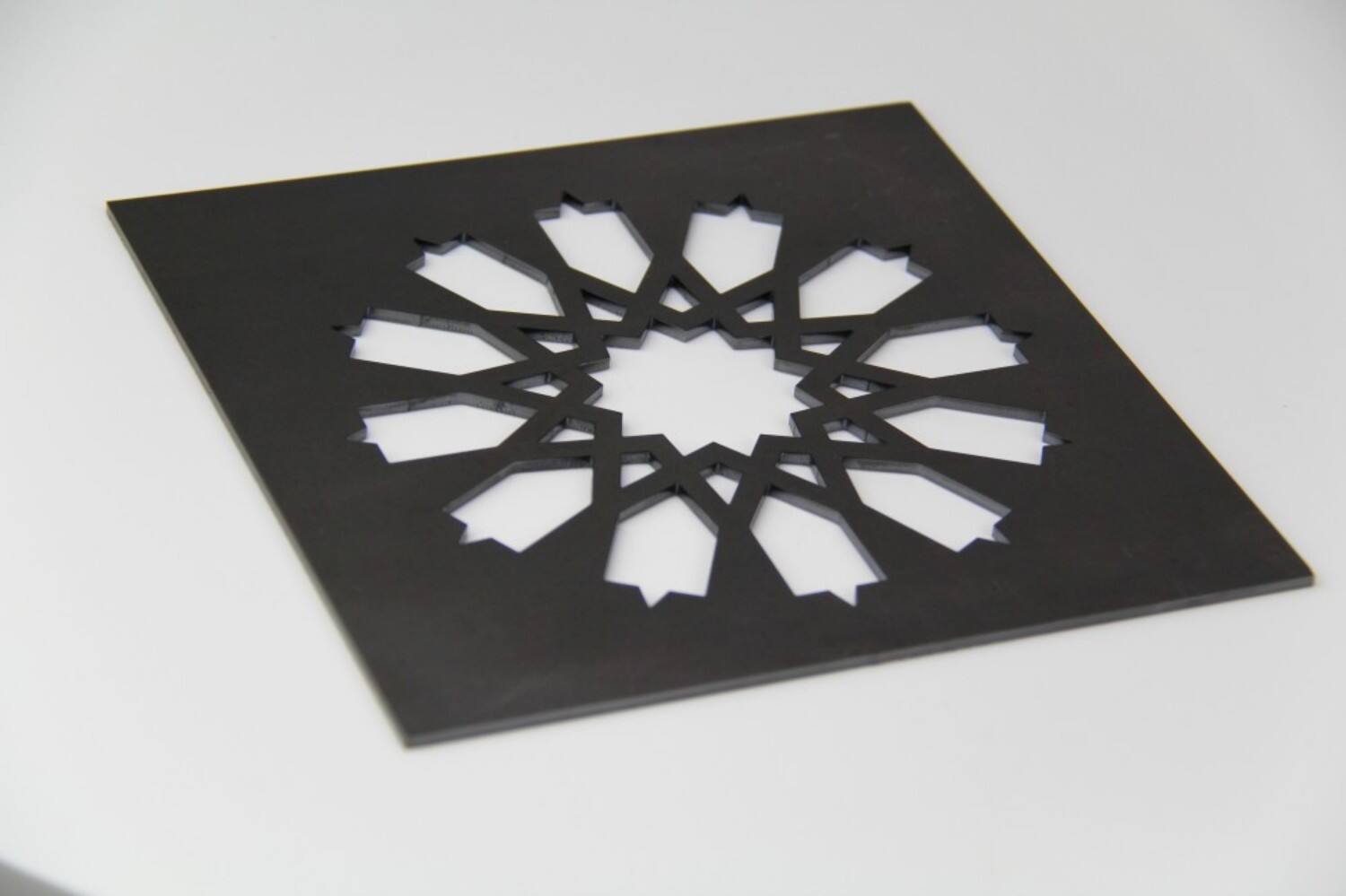

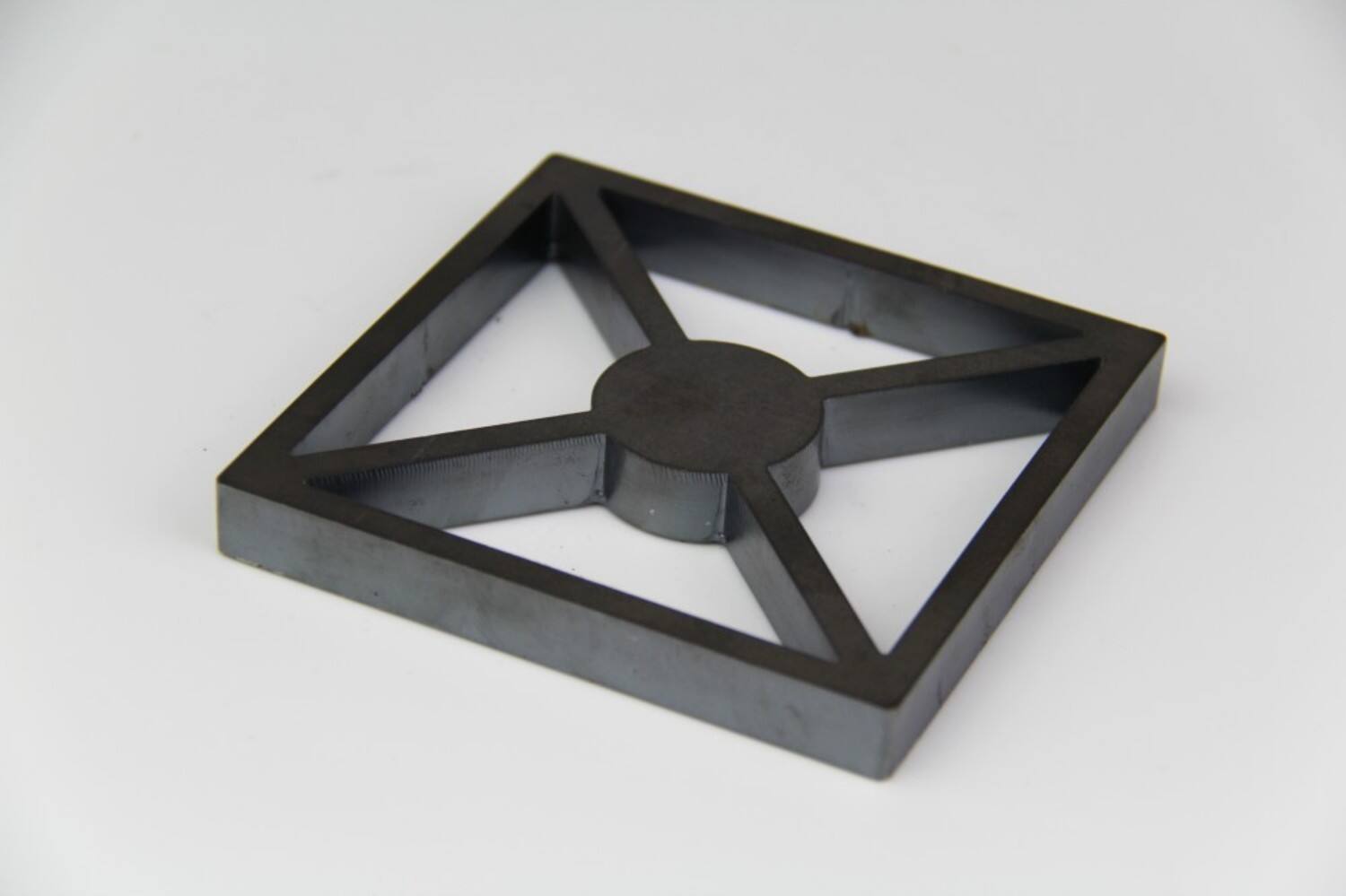

Cutting Samples:

High-Quality Components for Reliable Performance

The 3015L incorporates industry-leading components to ensure durability and optimal cutting performance:

- Laser source options: Raycus, Max, RECI, or IPG, providing flexible power choices from 1.5KW to 6KW to suit a variety of metal cutting applications.

- Motor and drivers: DELTA, Fuji, or Yaskawa, delivering smooth motion and precise control.

- Laser head: BOCI or RAYTOOLS for high-precision beam delivery.

- Electrical components: Schneider for reliable electrical performance.

- Electronically proportional valves: Japan SMC or Germany Lanny for precise gas control.

- Reducer, rack, and rail: Hongniu, ensuring long-lasting stability and accuracy.

- Control system: FSCUT, providing an intuitive interface and versatile cutting options.

Specifications and Performance

The 3015L offers a generous working area of 3000 × 1500 mm, accommodating a wide range of sheet sizes. With a power supply ranging from 10.5KW to 28KW and a gross weight of 2000kg, this machine is engineered for industrial efficiency while remaining manageable for standard workshop environments. Its overall footprint measures 4498 × 1913 × 1480 mm, combining operational capability with space-conscious design.

Applications and Versatility

This fiber laser cutting machine is ideal for cutting various metals including steel, stainless steel, aluminum, and other alloys, making it suitable for industries such as automotive, aerospace, electronics, signage, and general metal fabrication. The 3015L is built to handle high-volume production while delivering precision cuts, smooth edges, and minimal material wastage.

In summary, the 3015L Single Platform Fiber Laser Cutting Machine is a high-precision, cost-effective, and space-efficient solution for modern metal cutting operations. Its combination of lightweight design, robust components, and advanced cutting technology ensures superior performance, reliability, and versatility for professional workshops and industrial production lines alike.

Applications:

- Cutting metal sheets including stainless steel, carbon steel, aluminum, and alloys

- Fabrication for automotive, aerospace, electronics, and machinery industries

- Signage production, advertising panels, and decorative metalwork

- High-volume industrial production with precise, smooth cuts

- Custom metal part manufacturing requiring minimal material waste

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Cost-Effective Design: The 3015L combines high performance with affordability, offering an economical solution for workshops and industrial production without compromising on quality or precision.

- Lightweight Yet Stable Structure: Featuring an aviation aluminum profile crossbeam and scientifically optimized bed design, the machine is lightweight for easier handling but maintains exceptional stability and durability for long-term operation.

- High Precision and Smooth Operation: Equipped with dual-axis 25 precision linear guides and standard shaft output gear transmission, the machine ensures stable movement, precise cutting, and repeatable results for complex metal patterns.

- Optimized Blade Handling: The advanced blade structure with an additional pressing plate prevents workpiece adhesion during material picking, ensuring smooth operation and reliable blade pickup every time.

- Space-Saving and User-Friendly: Built-in chassis with suspension arm design allows for compact installation. The laser device can be integrated within the chassis, reducing workspace occupation and making operation and maintenance convenient.

- High-Quality Components: The machine uses top-tier components including Raycus / Max / RECI / IPG laser sources, DELTA / Fuji / Yaskawa motors and drivers, BOCI / RAYTOOLS laser heads, and Schneider electrical systems, ensuring consistent performance and long-term reliability.

- Versatility Across Applications: Capable of cutting stainless steel, carbon steel, aluminum, and other alloys, the 3015L is suitable for industries ranging from automotive and aerospace to electronics, signage, and general metal fabrication.

- Efficient Dust and Debris Management: Middle-through dust removal flue combined with a dedicated fan system keeps the work environment clean, improves cutting quality, and prolongs machine life.

- Flexible Laser Power Options: With power ranging from 1.5KW to 6KW and a wide working area of 3000 × 1500 mm, the machine can meet diverse production needs from small parts to large sheet cutting.

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Fiber Laser Cutting Machine

- CNC Laser Cutting Machine

- Metal Sheet Laser Cutting Machine

-

High-Precision Laser Cutting