Specifications:

| Model |

3015HSD |

| Working Area |

3000 × 1500 mm |

| Laser Power |

1.5KW – 30KW |

| Laser Source |

Raycus / Max / RECI / IPG |

| Laser Head |

BOCI / RAYTOOLS |

| Motor & Drivers |

DELTA / Fuji / Yaskawa |

| Control System |

FSCUT |

| Positioning Accuracy |

±0.03 mm |

| Re-positioning Accuracy |

±0.02 mm |

| Cutting Speed |

80 m/min |

| Cooling Method |

Water Cooling |

| Machine Size |

9600 × 2280 × 2230 mm |

| Gross Weight |

4800 kg |

Description:

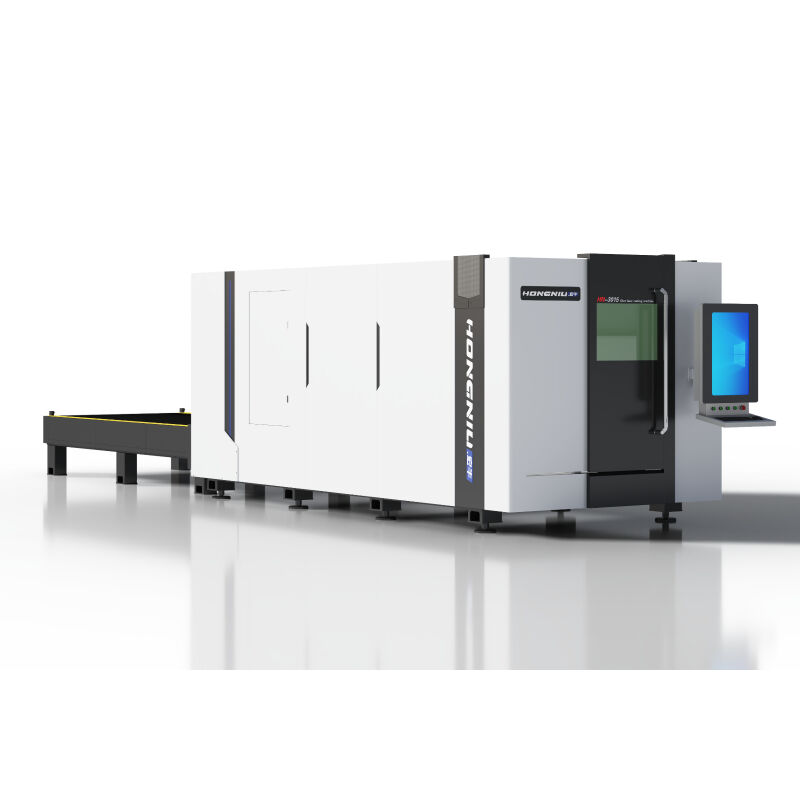

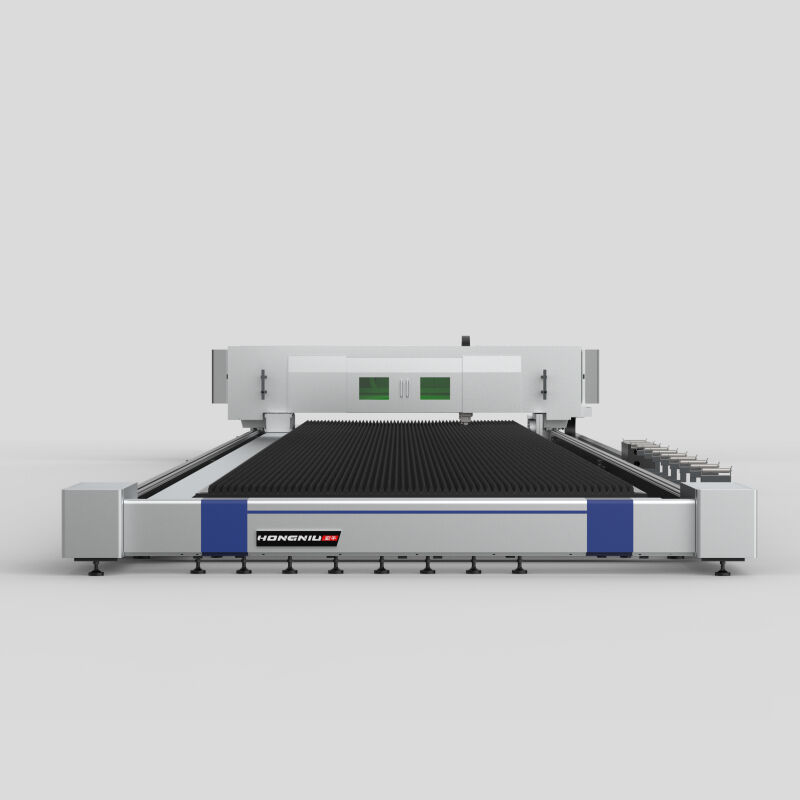

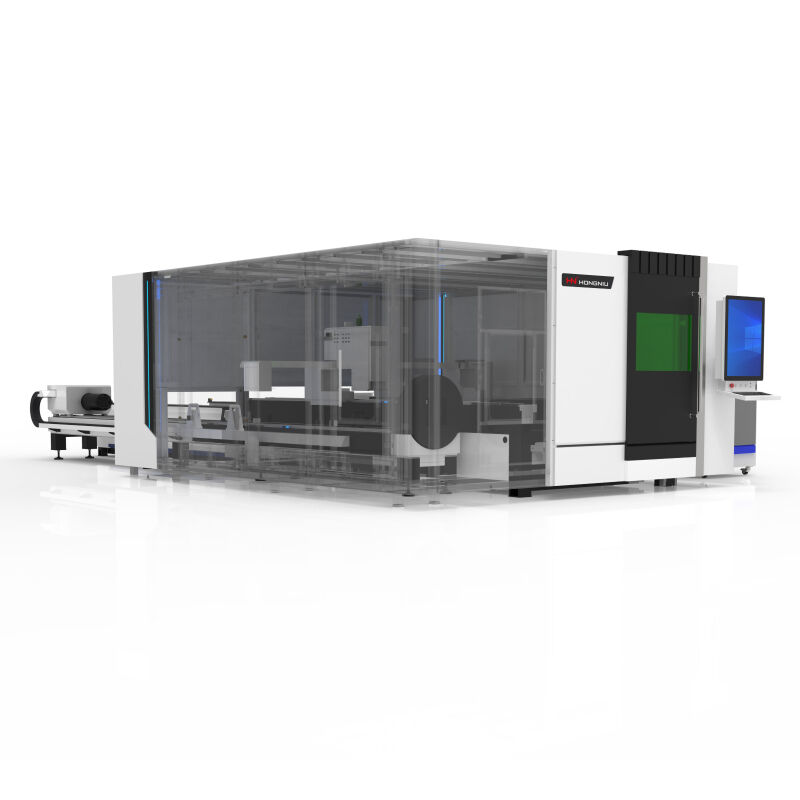

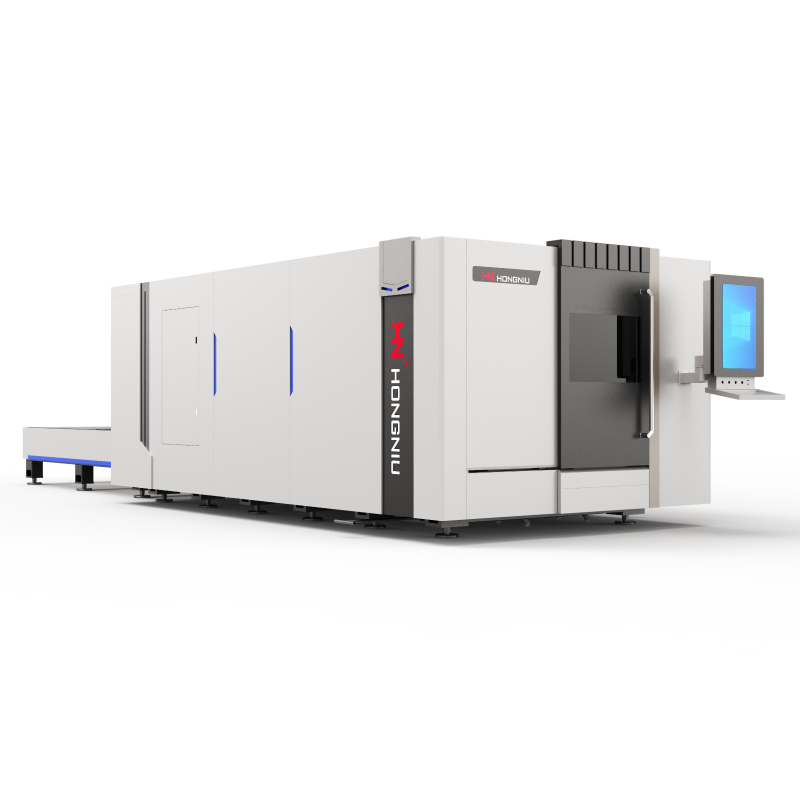

Container type enclosed exchange platform fiber laser cutting machine – Model 3015HSD

The 3015HSD is designed for high-power industrial cutting with stability, precision, and operational safety. Its container-type enclosed design ensures safe transportation, easy installation, and smoke-free operation.

Integrated Heavy-Duty Bed & Gantry Structure

The reinforced bed with cylinder clamps prevents table vibration, while the gantry double-drive structure guarantees smooth motion and accurate cutting, even for thick metal sheets.

Dual Platforms for Efficiency

Dual platforms allow simultaneous cutting, greatly increasing throughput for industrial production.

Advanced Dust & Smoke Management

Double air duct partition dust removal ensures precise extraction from the active cutting zone while keeping other areas inactive, maintaining a clean and safe workspace.

User-Friendly & Efficient Operation

Access doors on both sides provide convenient maintenance and overhauls. Fully enclosed structure with rear-mounted control cabinet and laser optimizes workflow.

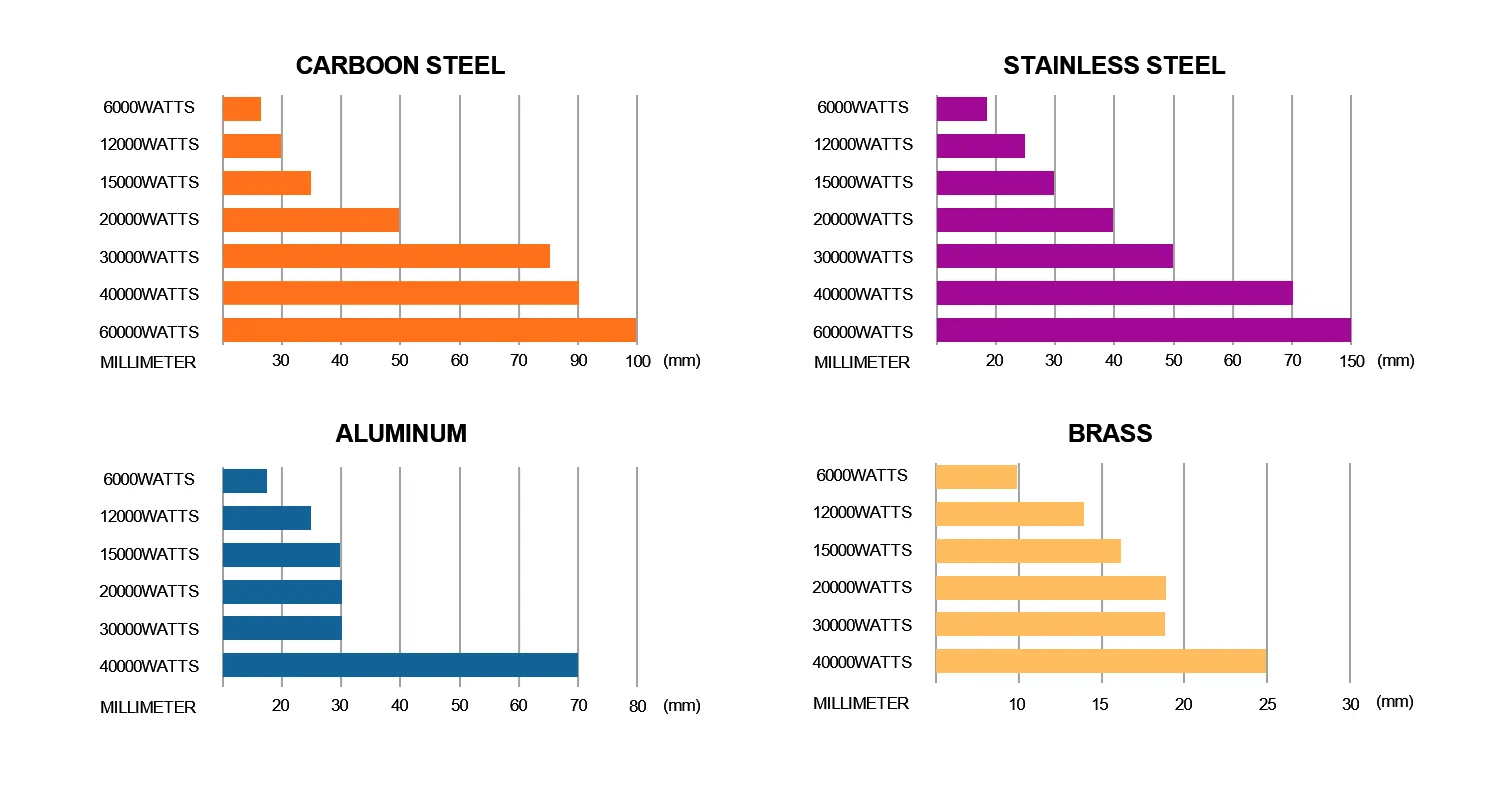

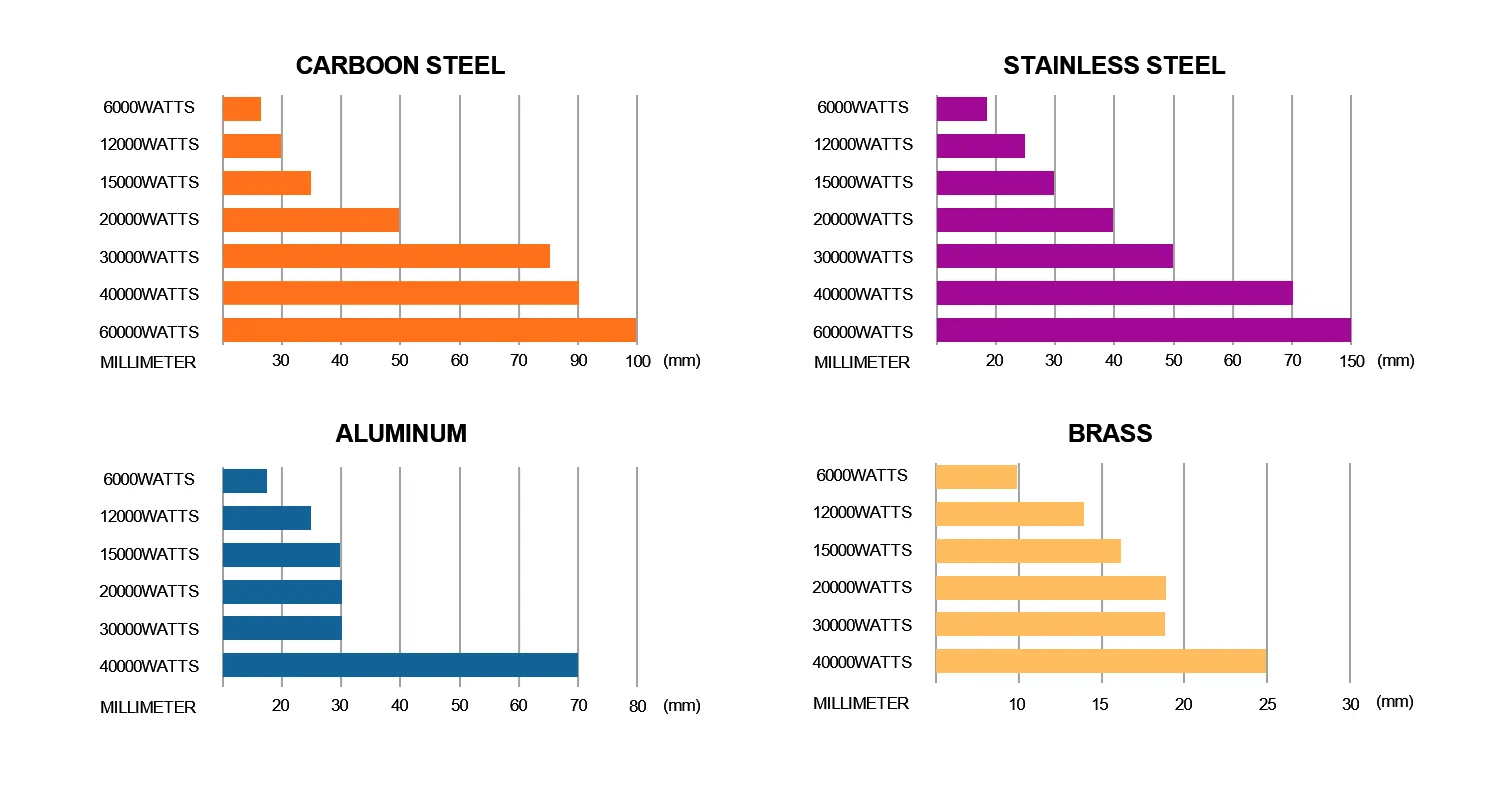

Cutting Parameters:

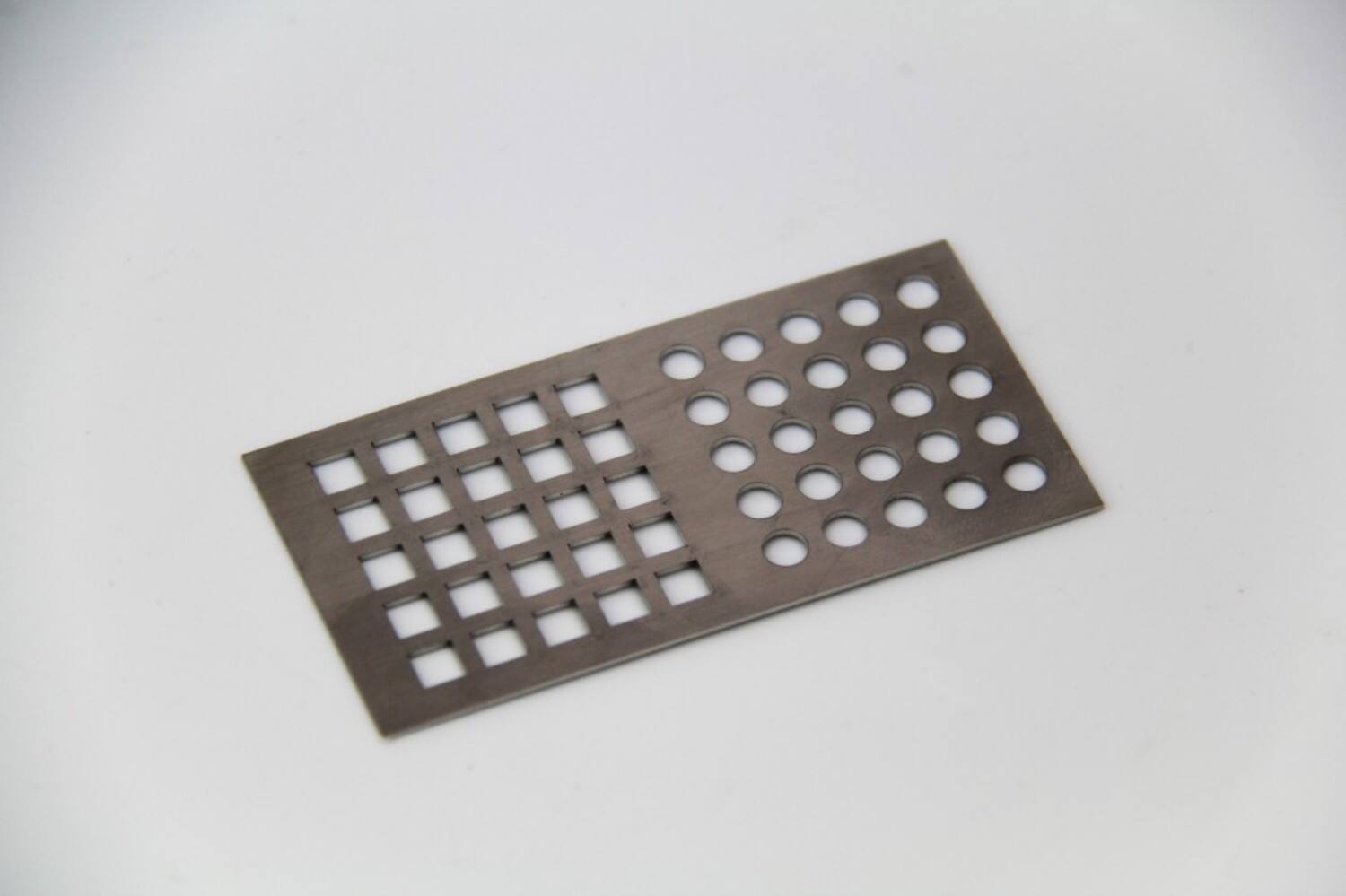

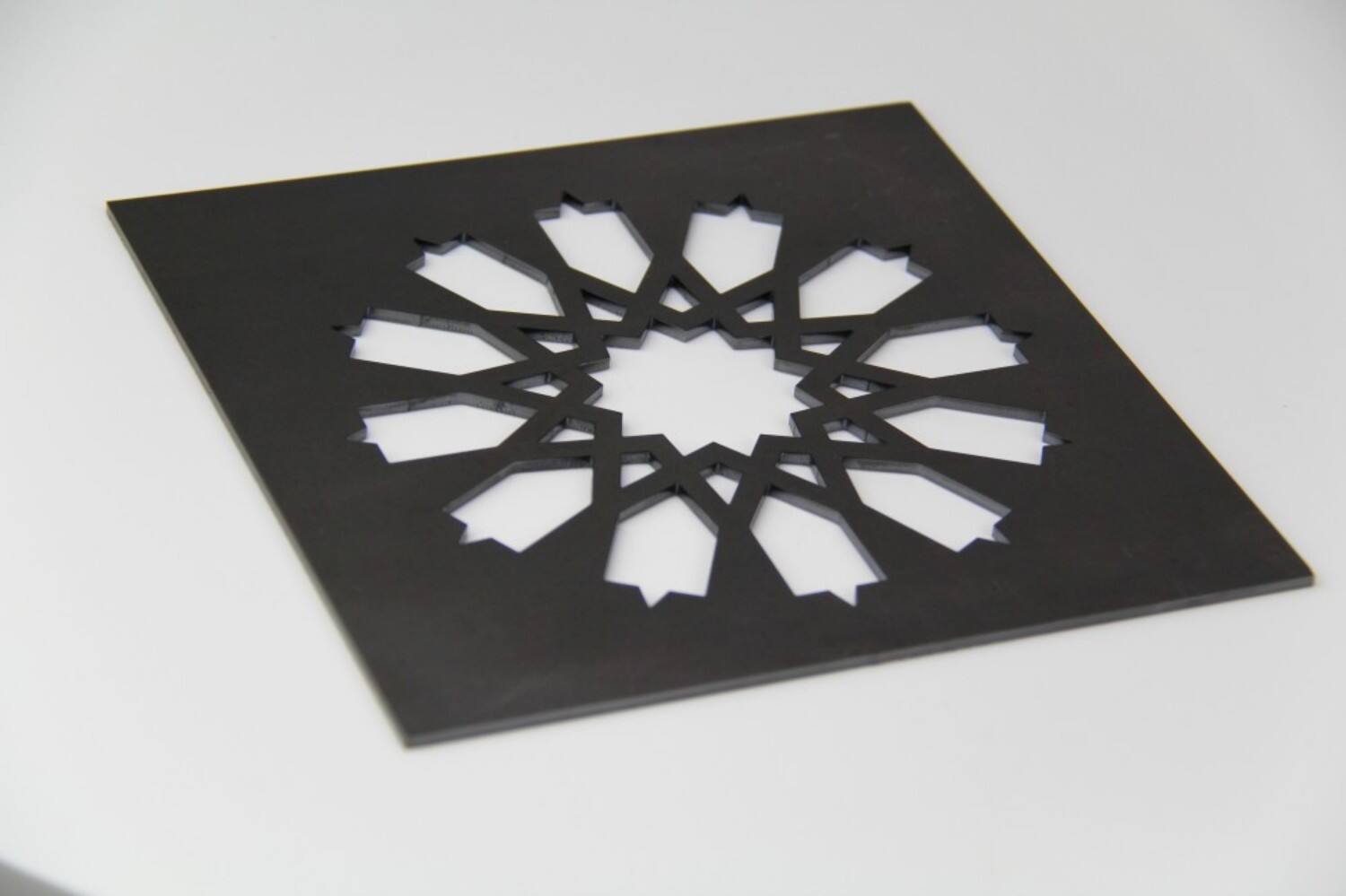

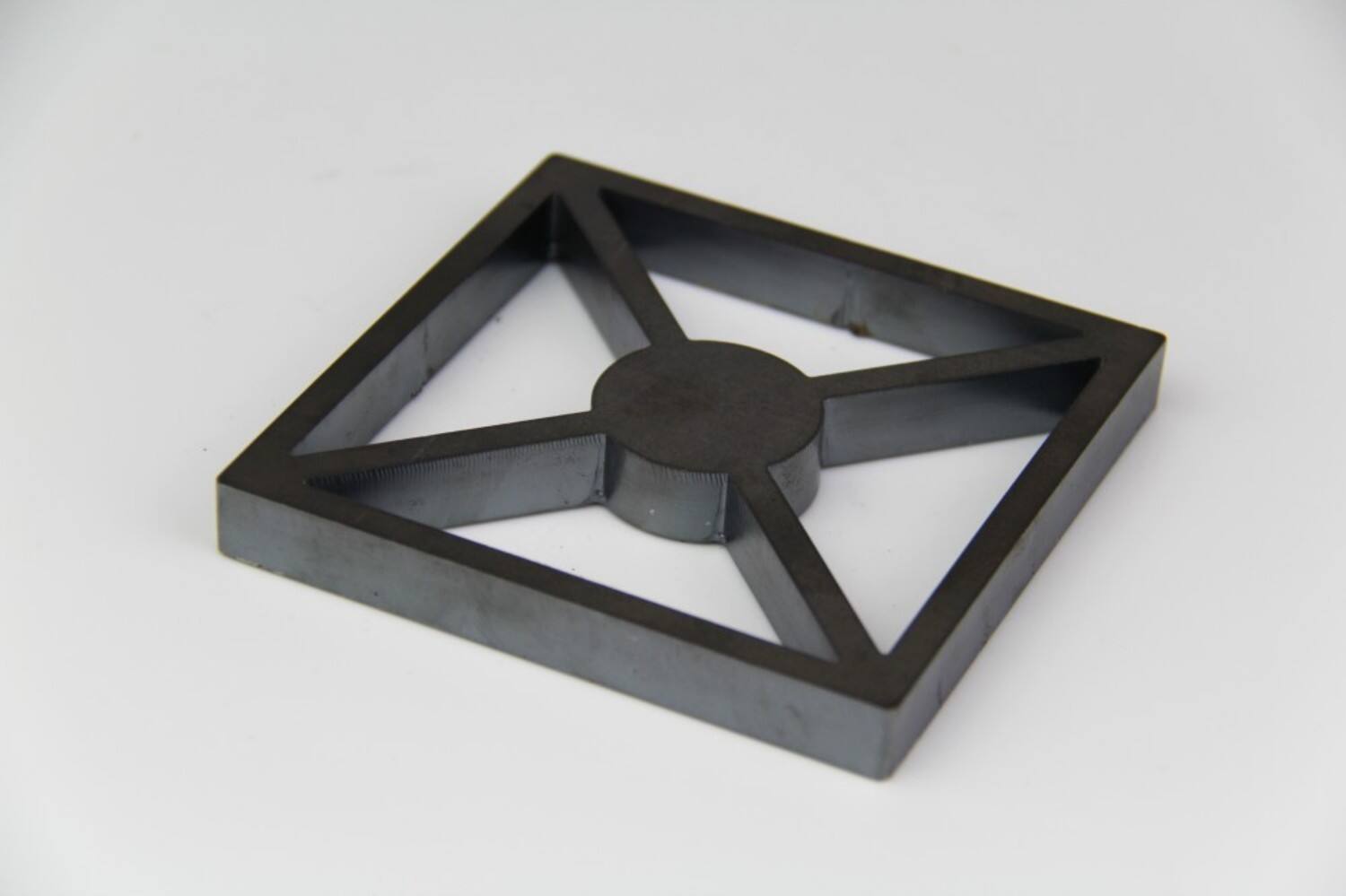

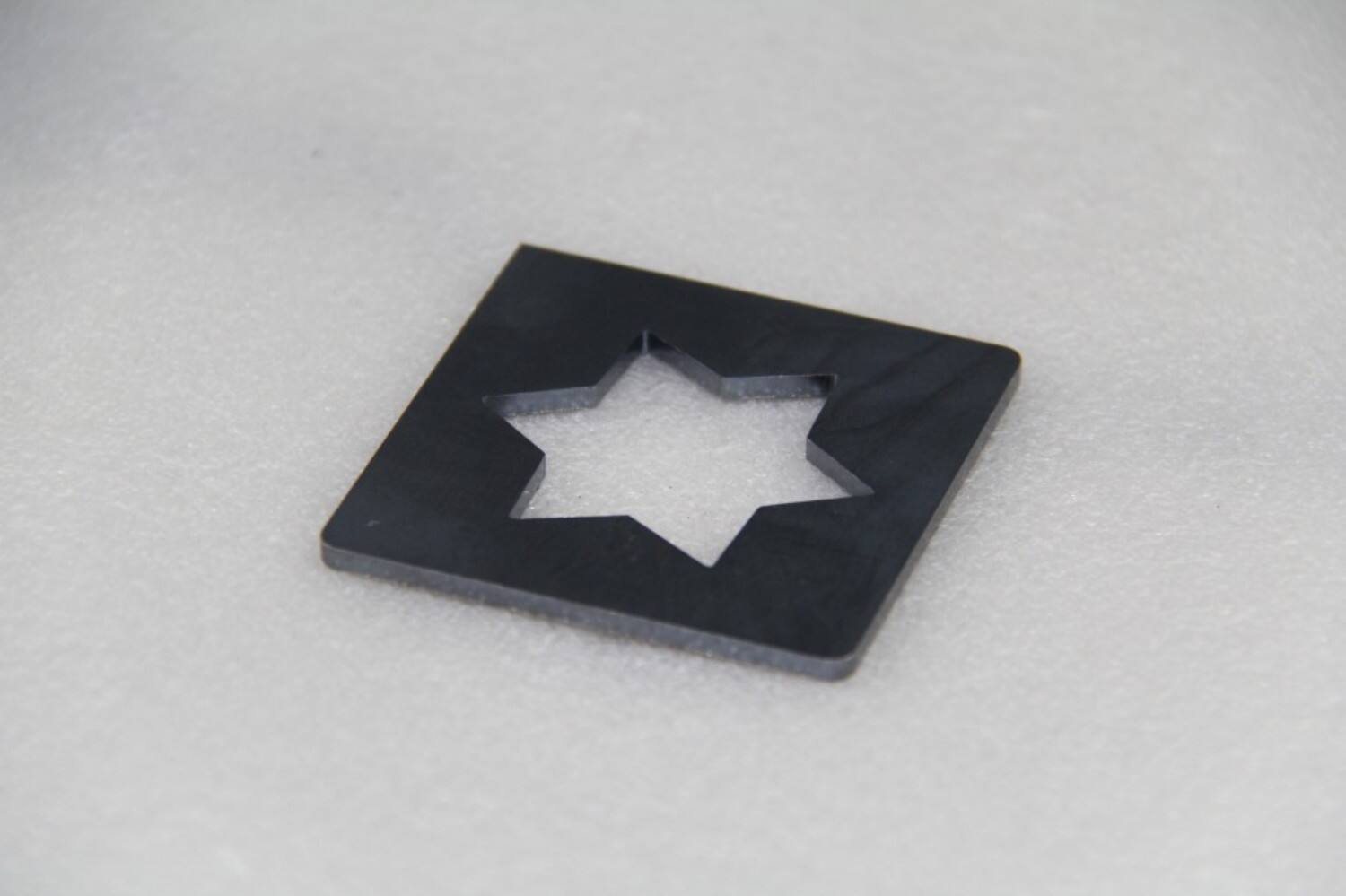

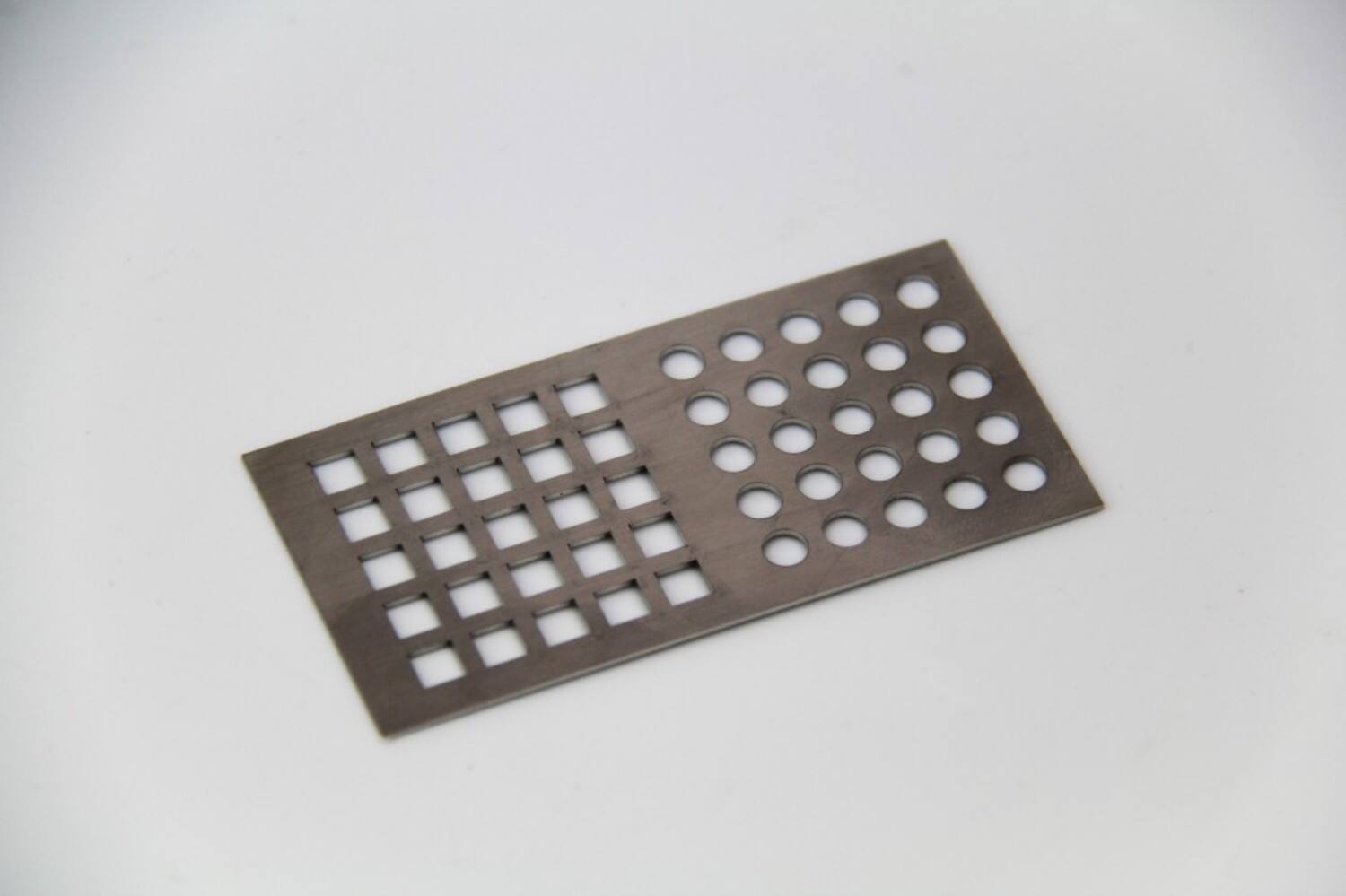

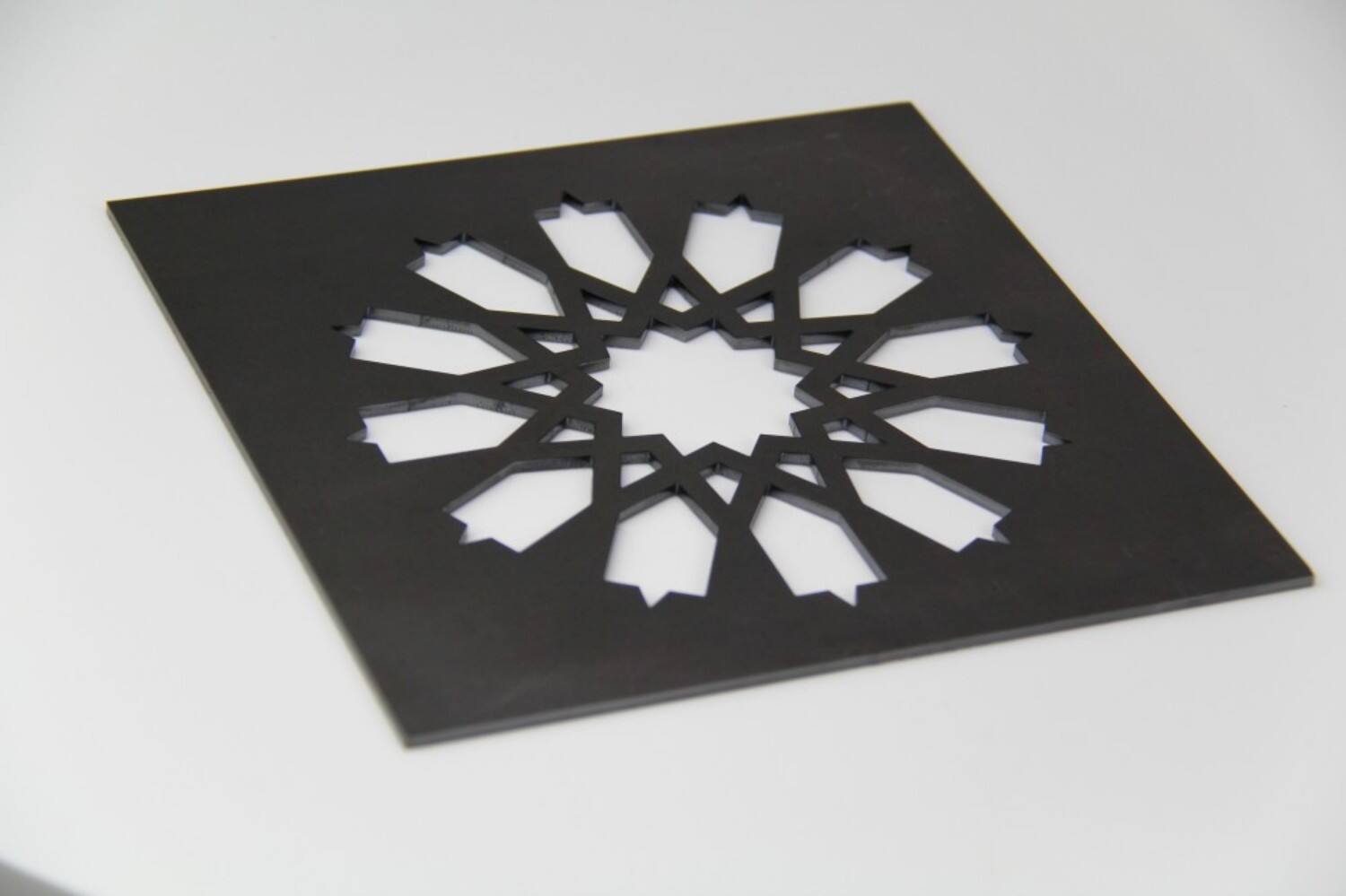

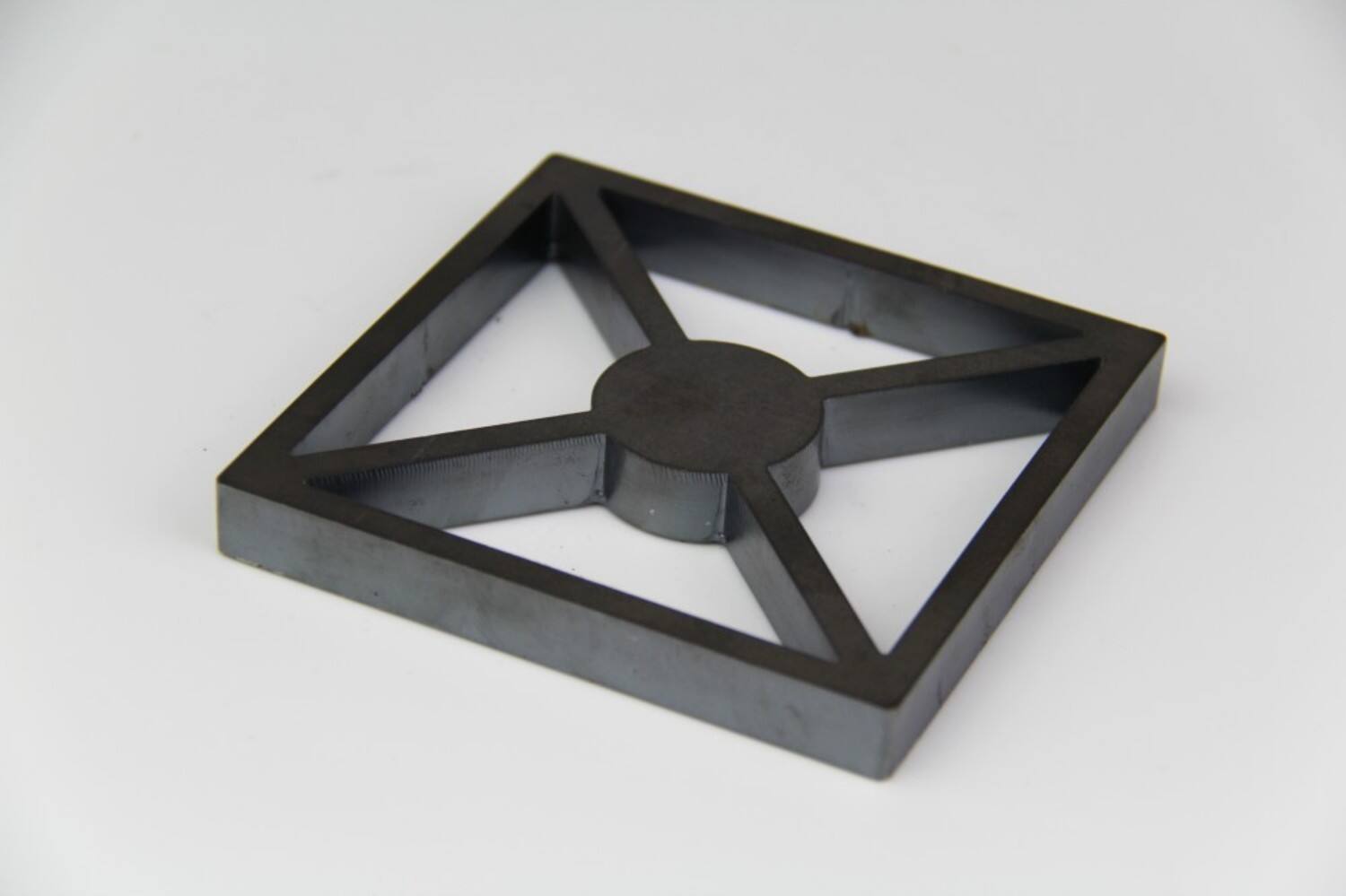

Cutting Samples:

High-Quality Components for Reliable Performance

- Laser Source: Raycus, Max, RECI, or IPG for high-power cutting.

- Laser Head: BOCI / RAYTOOLS with automatic focusing, anti-collision design, and intelligent monitoring.

- Motors & Drivers: DELTA, Fuji, or Yaskawa for precise motion and stability.

- Electrical Components: Schneider and Omron for reliable and safe operation.

- Control System: FSCUT supports CAD/DXF, multi-file processing, and one-stroke flying cuts.

- Cooling: Water chiller system protects both laser head and source, with alarm system for overheating.

- Automatic Lubrication: Programmable frequency and volume to extend service life.

Specifications and Performance

The 3015HSD offers a 3000 × 1500 mm working area with laser power up to 30kw, handling metal thicknesses from 1 to 50mm. Gantry double-drive structure, reinforced cylinder clamp, and high-speed servo motors deliver stable, precise, and high-speed cutting suitable for industrial production.

Applications and Versatility

Ideal for cutting metals including:

- Stainless Steel, Carbon Steel, Aluminum, Brass, Copper, Galvanized Sheet

Industries:

- Automotive & Aerospace

- Engineering Machinery

- Electronics & Home Appliances

- Advertising & Decorative Metalwork

- Panel Beating & Metallurgical Equipment

Applications:

- High-volume sheet metal cutting with dual platforms

- Production of automotive and aerospace components

- Fabrication of electrical enclosures and industrial equipment

- Signage and decorative metal panels

- Efficient cutting with minimal material waste

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Integrated Container Design: Safe transport, labor-saving installation.

- Dual Platforms: Maximize throughput and efficiency.

-

Closed Cabinet Design: Provides safety, smoke-free operation, and environmental protection.

- Reinforced Heavy-Duty Bed: Cylinder clamps prevent table vibration during cutting.

- Advanced Dust Extraction: Double air duct partition ensures precise smoke removal.

- Wide Laser Power Range: 1.5kw – 30kw for various materials and thicknesses.

- Easy Operation & Maintenance: Access doors and optimized layout of control cabinet and laser.

- Premium Components: Raycus/IPG lasers, BOCI/RAYTOOLS heads, FSCUT control, Schneider/Omron systems.

- Versatile Material Capability: Cuts metals from 1 to 50mm with precision and minimal waste.

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Fiber Laser Cutting Machine

- Container Type Laser Cutter

- Dual Platform Laser Cutting Machine

-

High-Efficiency Sheet Metal Laser Cutter