Core Specifications:

| Model |

3015E |

| Working Area |

3000 × 1500 mm – 6000 × 1500 mm |

| Laser Power |

1.5KW – 12KW |

| Laser Source |

Raycus / Max / RECI / IPG |

| Laser Head |

BOCI / RAYTOOLS |

| Motor & Drivers |

DELTA / Fuji / Yaskawa |

| Control System |

FSCUT |

| Cutting Speed |

80 m/min |

| Positioning Accuracy |

±0.03 mm |

| Re-positioning Accuracy |

±0.02 mm |

| Cooling Method |

Water Cooling |

| Machine Size |

4498 × 2030 × 1948 mm |

| Gross Weight |

2500 kg |

| Applicable Materials |

Stainless Steel, Carbon Steel, Aluminum, Brass, Copper |

Description:

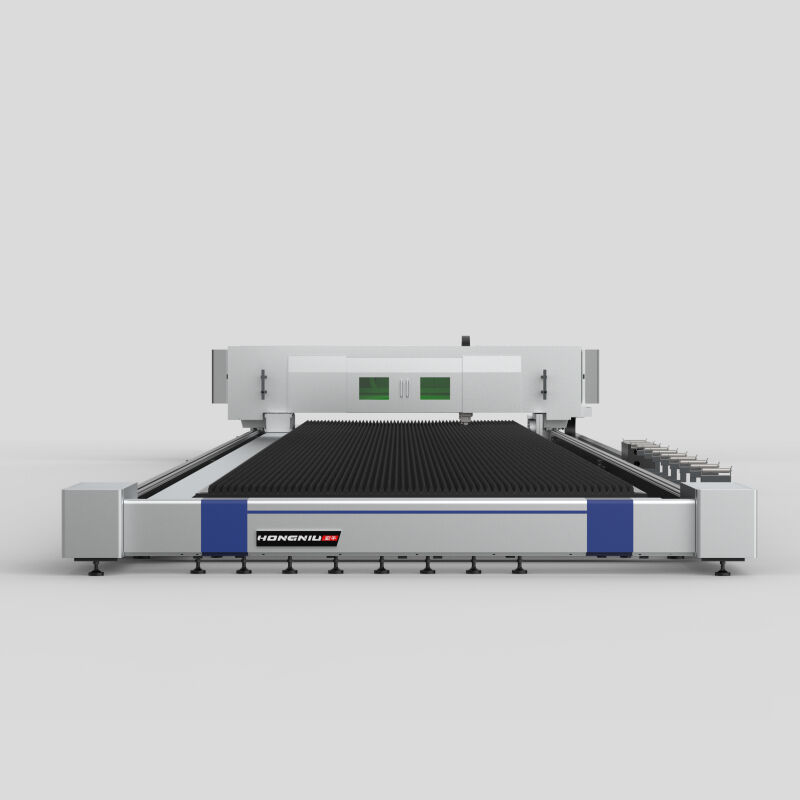

Single Platform Fiber Laser Cutting Machine – Model 3015E

The 3015E Single Platform Fiber Laser Cutting Machine is engineered for manufacturers who need accuracy, speed, and long-term reliability in sheet metal processing. Built with a reinforced heavy-duty bed and advanced motion components, the 3015E delivers consistent cutting performance across a wide range of metal materials—from stainless steel to copper, brass, and aluminum.

High-Strength Bed for Stable Production

The machine adopts a honeycomb carbon structural bed that undergoes annealing, vibration stress relief, and secondary aging treatment. This ensures excellent rigidity, long-term precision, and resistance to deformation, even during heavy-duty, high-temperature cutting.

Advanced Dust Removal System

A double-duct extraction design ensures clean and efficient dust removal. The system automatically opens the duct in the active cutting zone (A/B) while closing the others, maintaining powerful suction exactly where it’s needed. This delivers a cleaner workshop and better long-term cutting quality.

Optimized Beam Design

The third-generation aviation aluminum crossbeam offers high strength and low weight, reducing motor load and improving dynamic response during high-speed cutting. This contributes to cleaner edges, higher accuracy, and stable operation at top speeds.

Space-Saving Cantilever Control

The suspended cantilever computer console saves floor space and provides a cleaner, more user-friendly layout. Operators benefit from easier access and more efficient workflow around the machine.

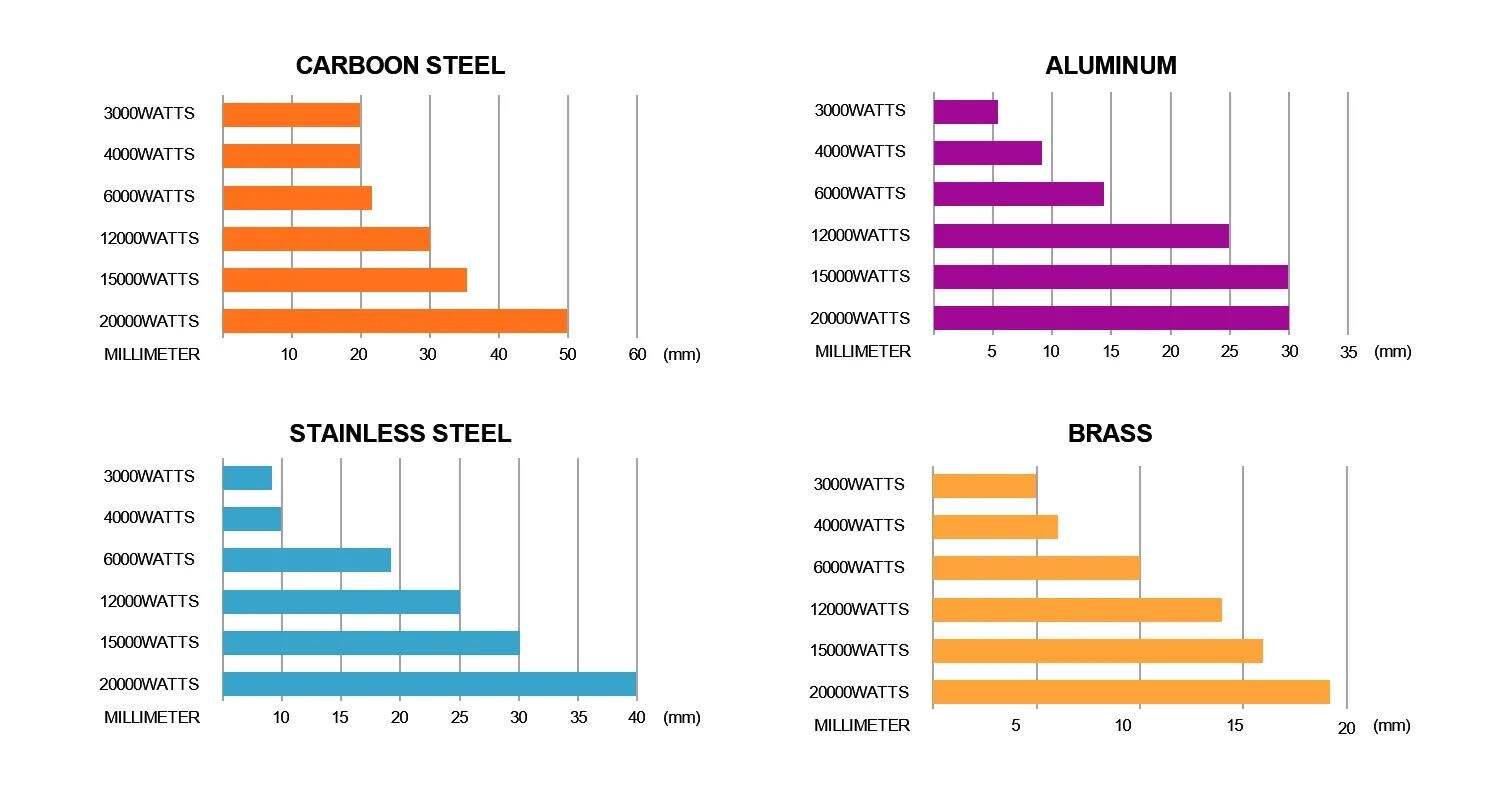

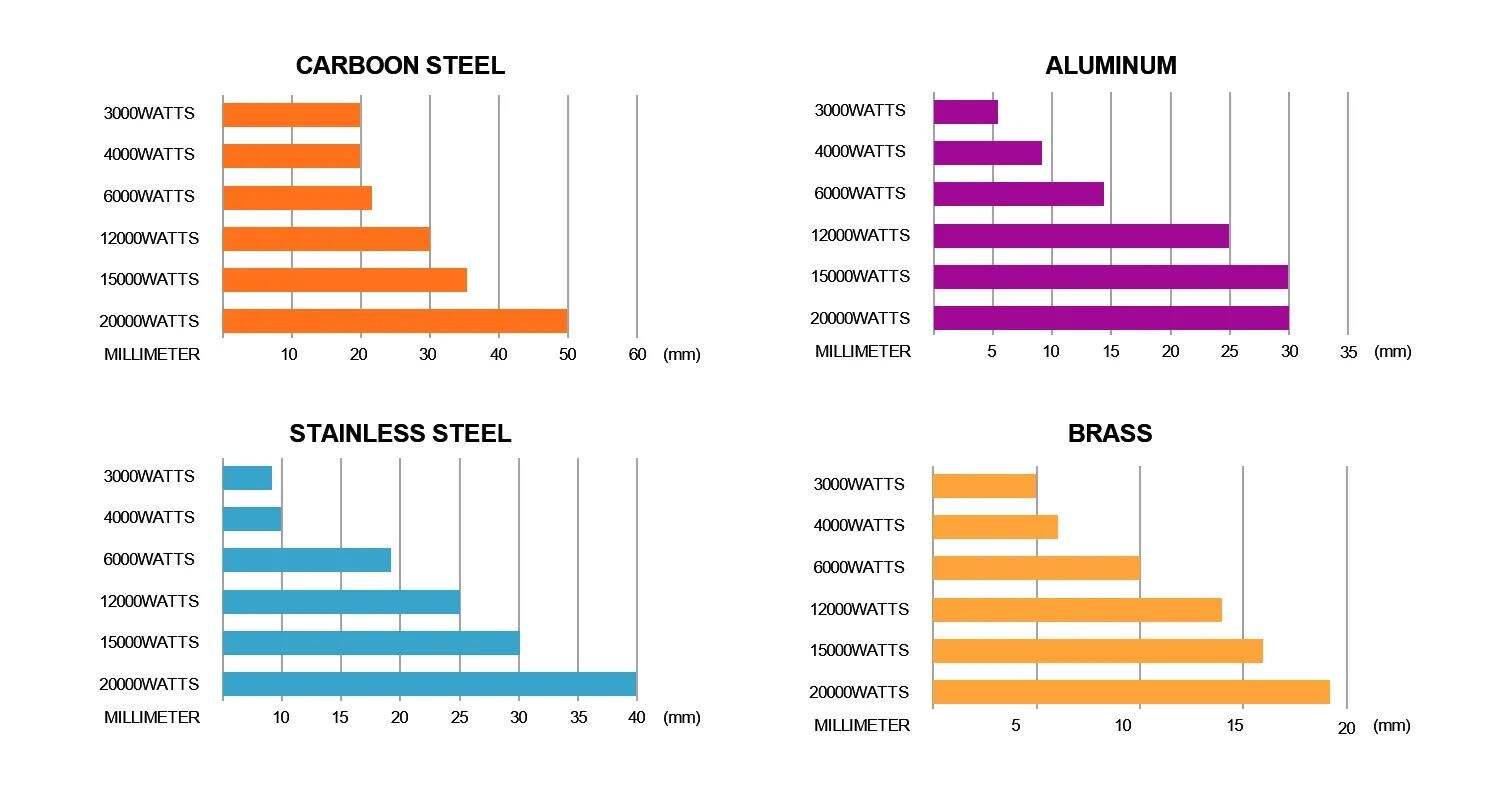

Cutting Parameters:

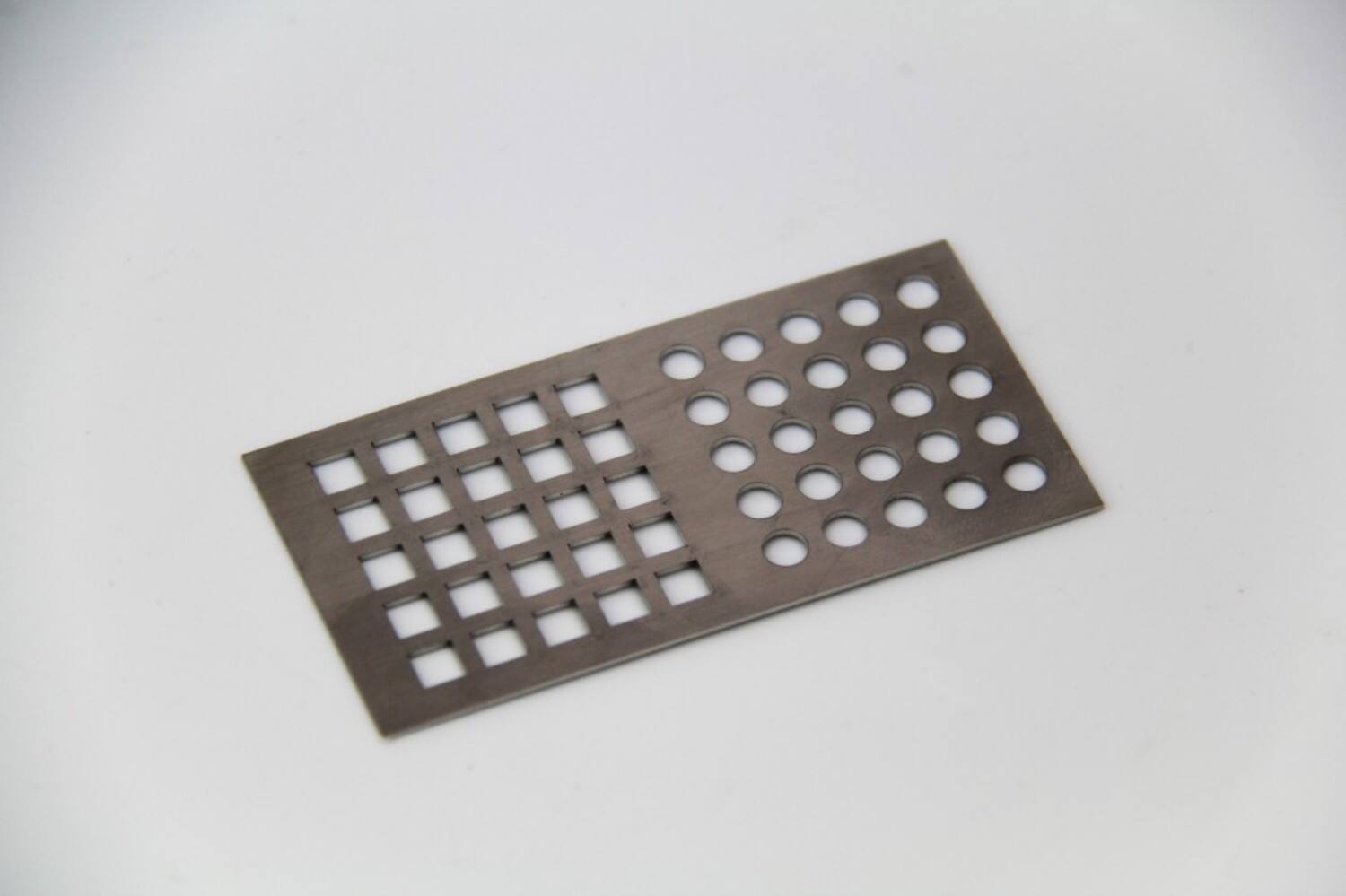

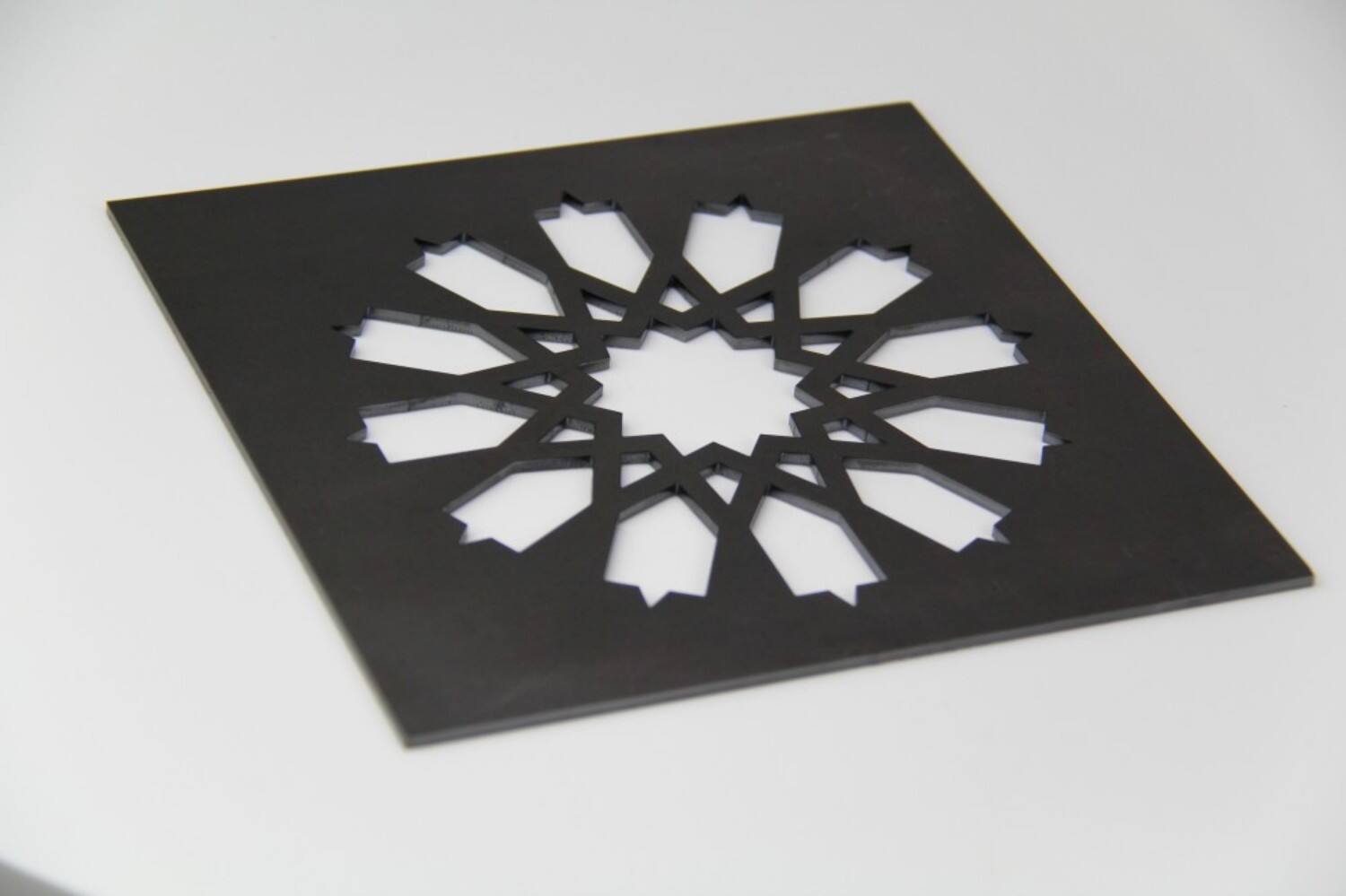

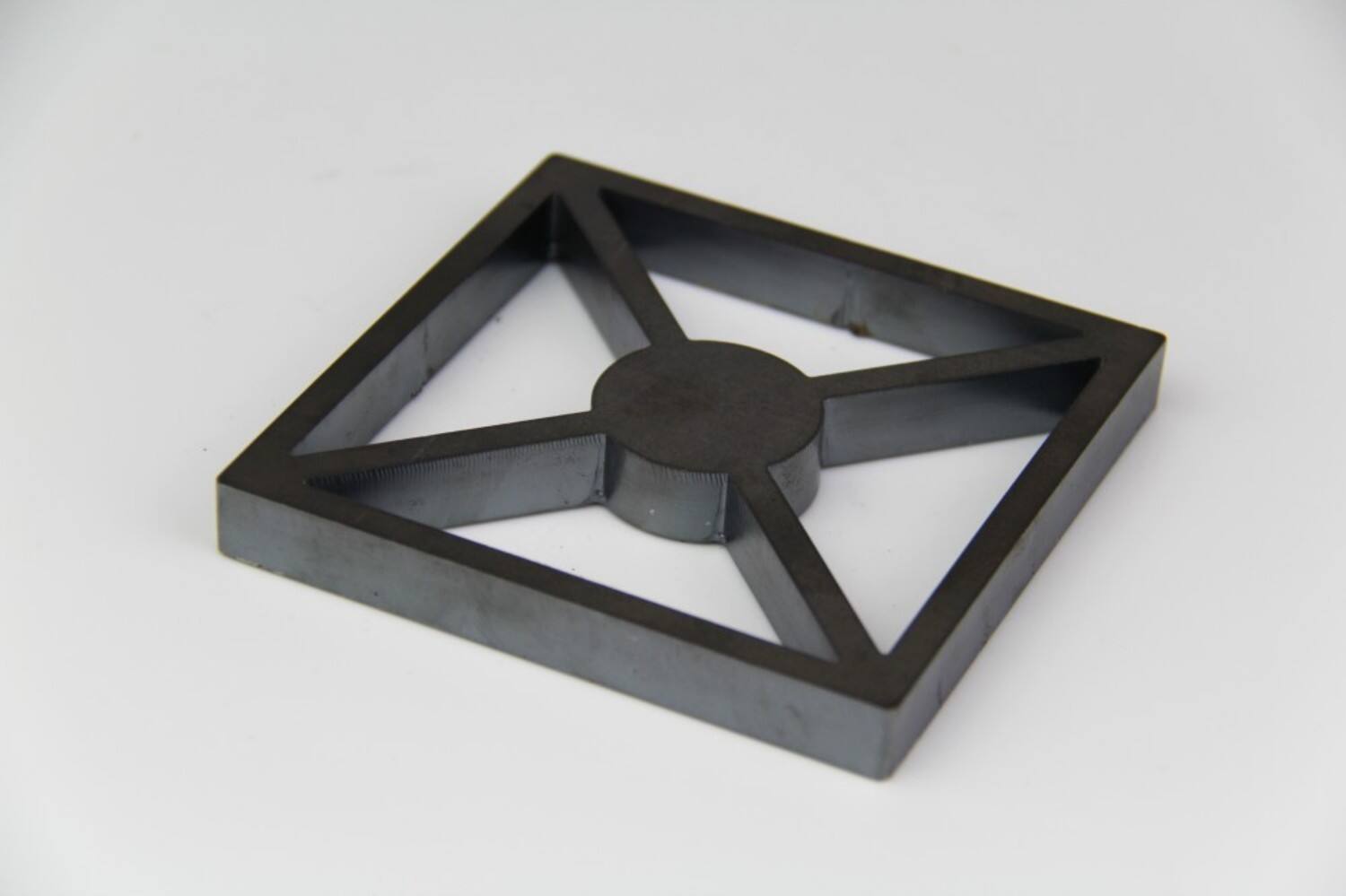

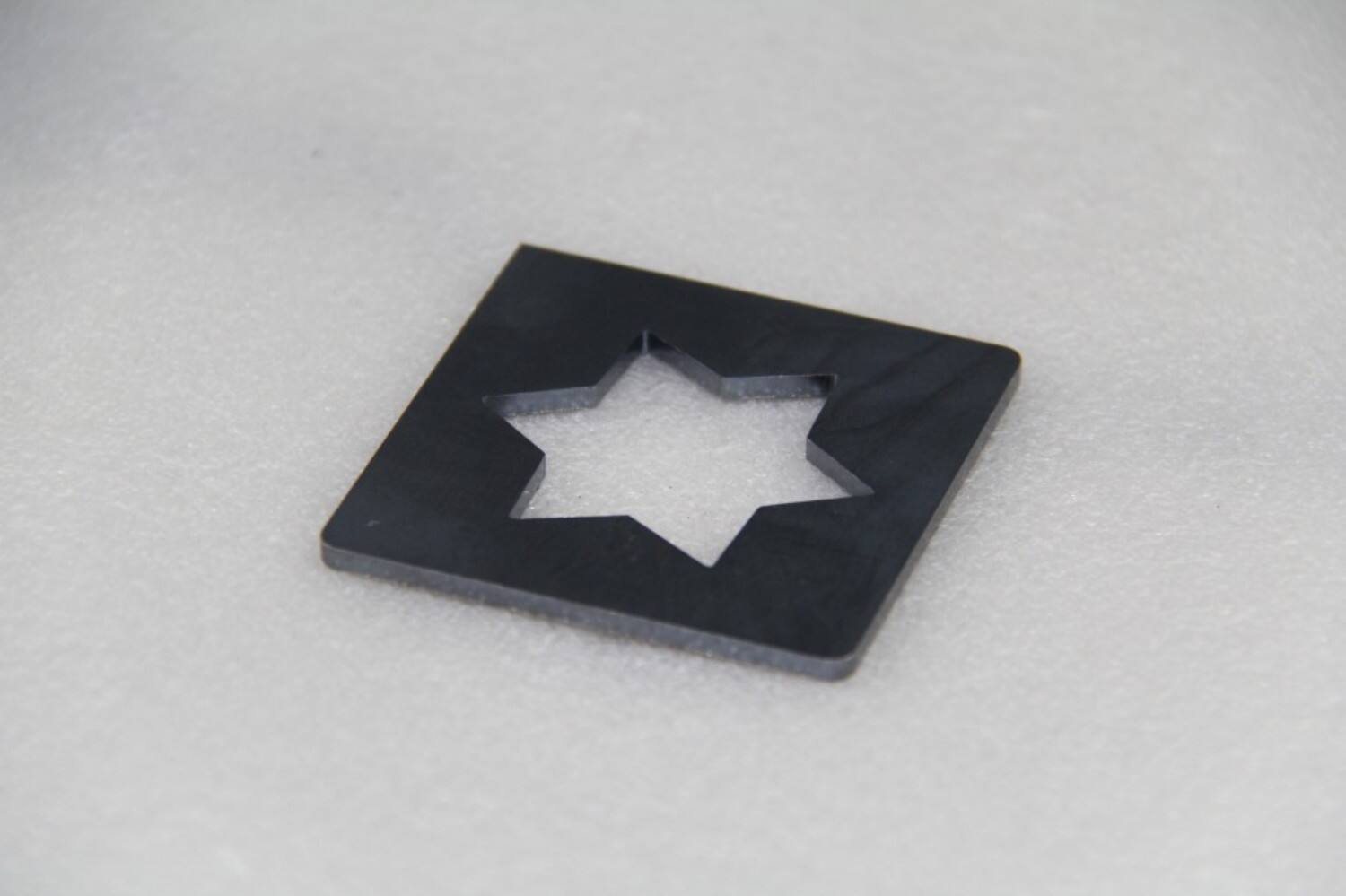

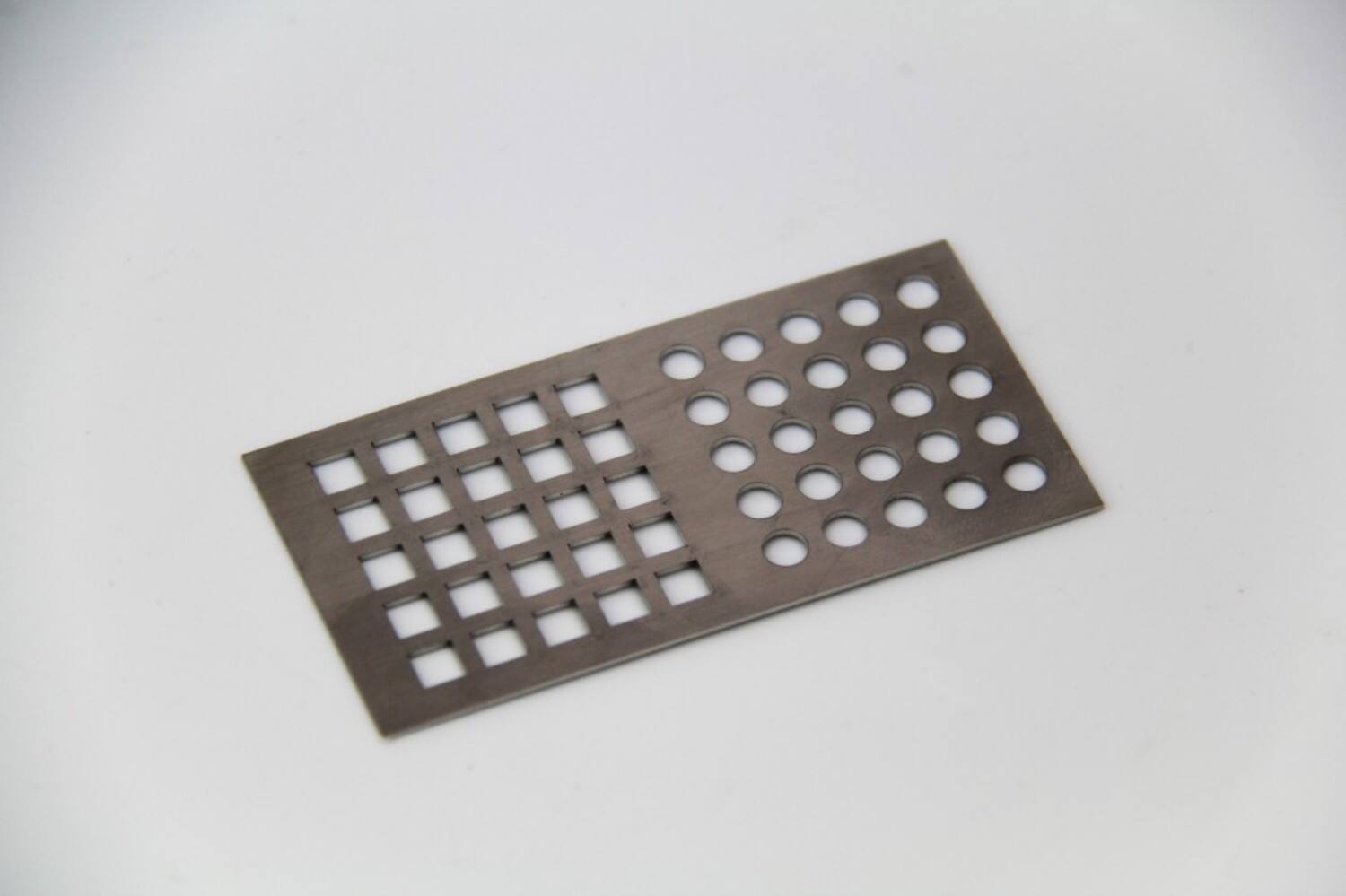

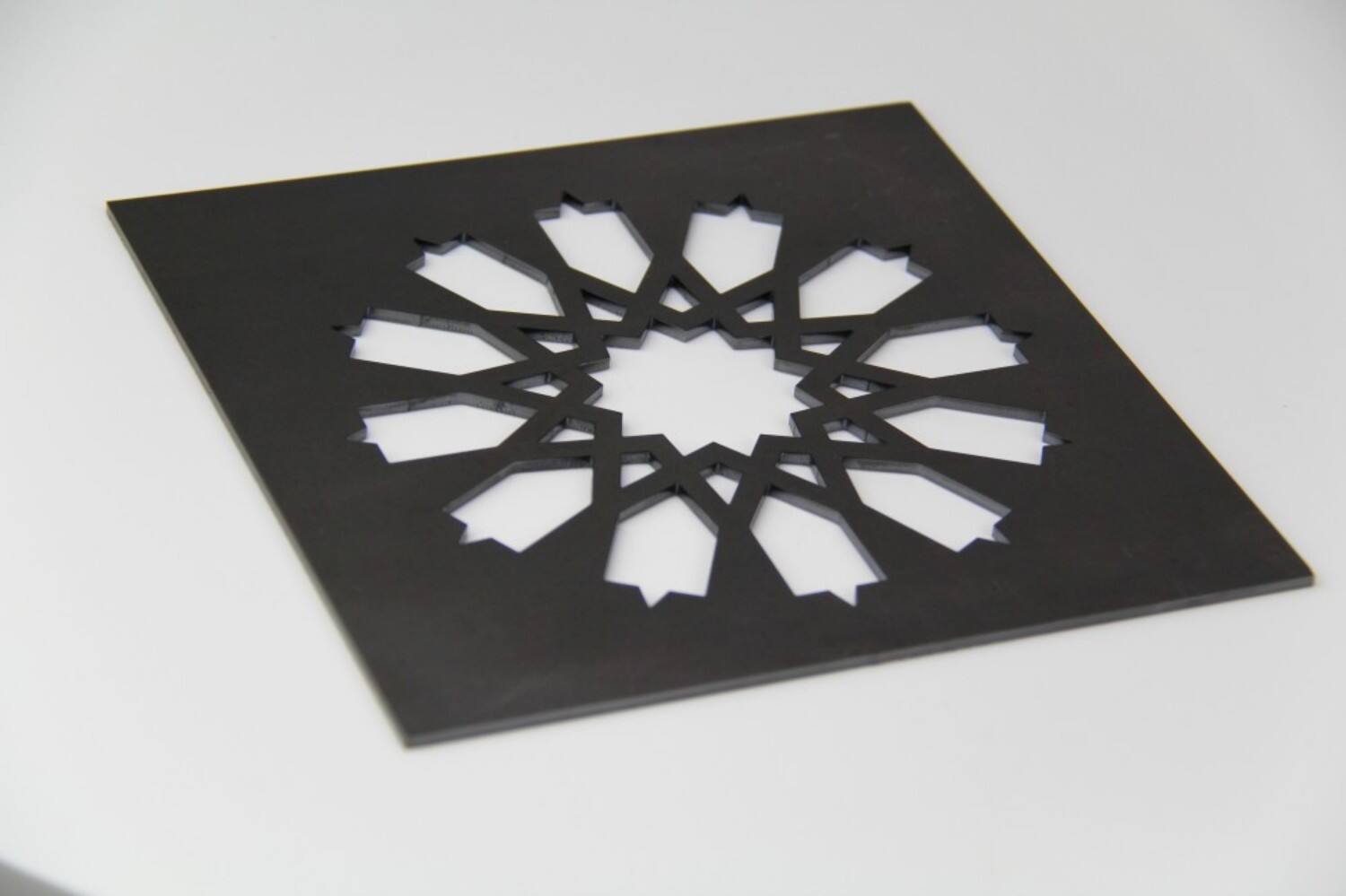

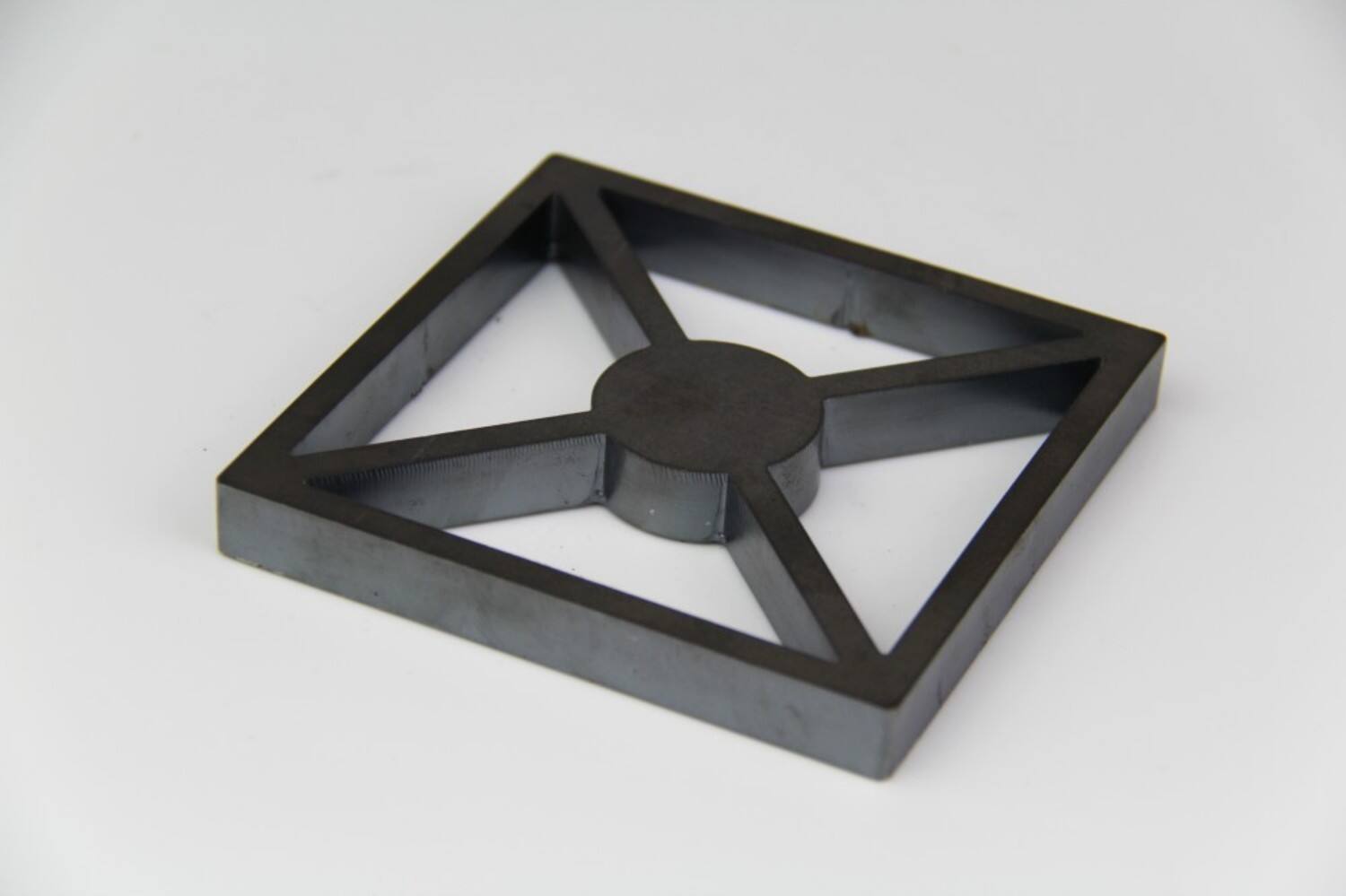

Cutting Samples:

High-Quality Components for Reliable Performance

- Laser Source: Raycus, Max, RECI, or IPG options from 1.5kW to 12kW for flexible cutting requirements.

- Servo Motors & Drivers: DELTA, Fuji, or Yaskawa for stable motion, quick response, and precise positioning.

- Laser Head: BOCI or RAYTOOLS—both known for reliable autofocus performance and stable beam delivery.

- Electrical Components: Schneider for consistent safety and electrical reliability.

- Proportional Valves: Japan SMC or Germany Lanny for precise gas control.

- Transmission Components: Hongniu reducer, rack, and rail ensure smooth motion and long service life.

- Control System: FSCUT provides intuitive operation, fast processing logic, and multiple smart cutting functions.

Specifications and Performance

With a working area of up to 3000 × 1500 mm and power options ranging from 1.5kW to 12kW, the 3015E is built for both small-scale precision cutting and high-volume industrial production.

Its reinforced 2500kg machine frame and 80m/min cutting speed combine accuracy with efficiency. The FSCUT control system supports CAD/DXF formats, automatic lubrication, and intelligent cutting modes to streamline daily operations.

Applications and Versatility

The 3015E is suitable for cutting a wide range of metals, including:

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Alloy Plates

Industries that commonly use this machine:

- Engineering Machinery

- Aerospace

- Automotive Manufacturing

- Electronics

- Home Appliances

- Metal Fabrication

- Advertising and Decoration

Applications:

-

Sheet metal cutting for stainless steel, carbon steel, and alloys

- Fabrication for automotive parts, aerospace components, and industrial equipment

- Electrical enclosures, machinery frames, and precision metal components

- Signage, advertising panels, and decorative metalwork

- High-volume industrial cutting requiring accuracy and minimal waste

Application Industry Scenario Diagram

|

|

|

|

| Aerospace Industry |

Automotive Industry |

Furniture & Decoration |

Metal Fabrication Machinery |

Competitive Advantage:

- Heavy-Duty Structural Bed: Honeycomb carbon design with full annealing and stress relief ensures lasting accuracy without deformation.

- Zone-Controlled Dust Removal: Dual duct system increases suction strength, keeps the workshop cleaner, and improves cutting quality.

- High-Speed Cutting Performance: Third-generation aviation aluminum beam enhances rigidity and reduces inertia for faster, smoother motion.

- Smart, Clean Layout: Cantilever computer console saves space and improves operational convenience.

- Premium Components: Equipped with top brands including Raycus/IPG laser sources, Yaskawa servo motors, Schneider electrical parts, and BOCI/RAYTOOLS laser heads.

- Strong Versatility: Handles up to 40 mm metal thickness and multiple material types with precision.

- Automatic Lubrication System: Extends the lifespan of key components while reducing manual maintenance.

- Reliable Global Support: 2-year warranty, training availability, 24-hour after-sales response team, and comprehensive pre-delivery debugging.

Quality Inspection & Manufacturing Process:

| Pre-Assembly Inspection |

Precision Machining |

Vibration & Natural Aging |

| Each machine component undergoes precise measurement of guide rail straightness and geometric accuracy. Altimeters verify linear dimensions to ensure every part meets design standards. |

High-speed rough machining removes burrs and excess material, followed by fine processing for smooth, flat surfaces that ensure long-term cutting precision. |

Residual internal stress is released through vibration and natural thermal cycles. This process enhances structural rigidity, stability, and dimensional accuracy of the machine bed. |

| Assembly Process |

Welding & Structural Strength |

Final Inspection & Testing |

| Guide rails and gear racks are installed and calibrated by skilled technicians using precision tools, ensuring smooth transmission and stable machine performance. |

CO₂ shielded welding guarantees firm, defect-free joints, improving overall frame strength, durability, and cutting stability. |

Dynamic performance tests check positioning accuracy, repeatability, and micro displacement precision. Interferometers compensate for any rack errors, ensuring superior cutting accuracy. |

Tag:

- Fiber Laser Cutting Machine

- CNC Laser Cutting Machine

- Metal Sheet Laser Cutting Machine

-

High-Precision Laser Cutting