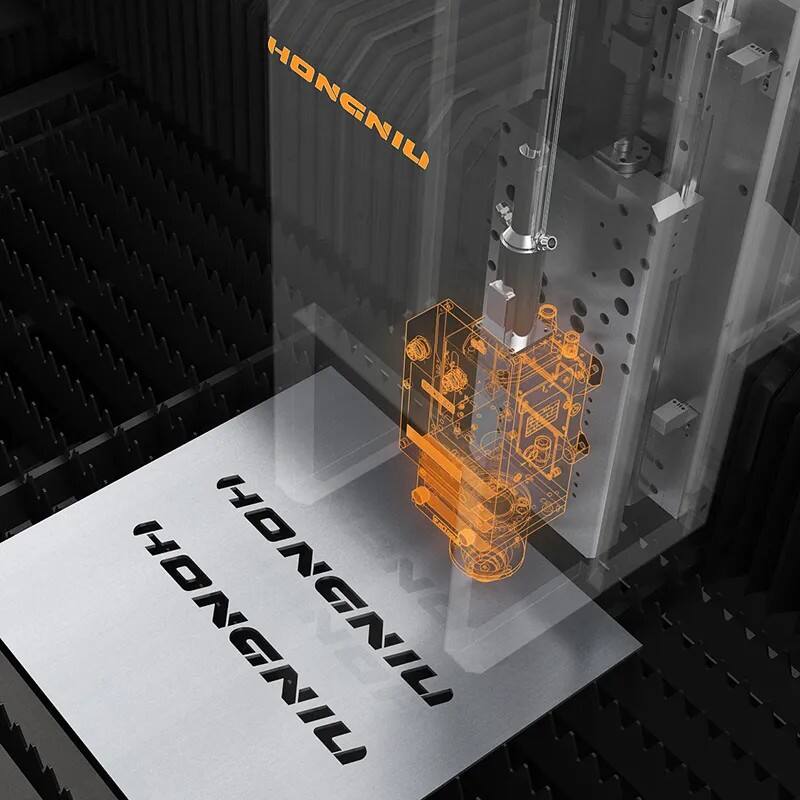

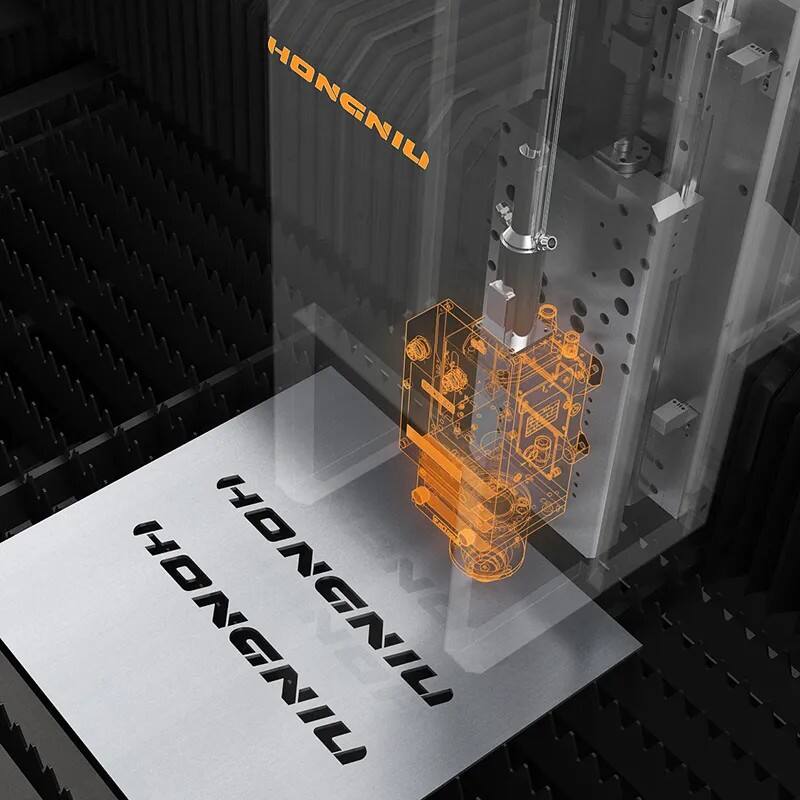

Selecting the right fiber laser cutting machine has become one of the most important decisions for modern metal fabrication shops. As fiber laser technology continues to surpass CO₂ and plasma systems in speed, efficiency, and edge quality, more manufacturers are moving toward mid-power fiber lasers—particularly those in the 1500W to 6000W range—for daily sheet-metal processing.

But not all fiber lasers are created equal, and the ideal machine depends heavily on the thickness, material type, expected production volume, and future business expansion. This article explores the essential factors to consider when choosing a fiber laser cutting machine for 3mm to 20mm metal sheets, with a strong focus on why 3000W has become the most popular and cost-effective power level.

Understanding How Laser Power Influences Cutting Performance

Laser power is often the first specification buyers notice, and for good reason: it directly impacts cutting speed, piercing capability, edge quality, and the range of supported materials. For sheet metal in the 3mm–20mm category, the majority of workshops lean toward power levels between 1500W and 6000W.

Lower-power systems, such as 1000W or 1500W, are excellent for thin sheet metal, signage, decorative panels, and electronics housings. However, when the workload includes stainless steel above 4mm or carbon steel above 6mm, low-power systems can become slow and unstable, especially during thicker cuts or high-volume production.

On the opposite end, high-power machines above 10kW offer impressive thickness capacity and exceptional speed, but they are significantly more expensive to purchase and operate. Their benefits are often underutilized in typical sheet-metal job shops, where most parts fall below 16mm.

Why Material Type Matters Just as Much as Thickness

Different metals interact differently with fiber laser light. For instance:

Carbon steel absorbs laser energy well, allowing even 1500W systems to process moderate thicknesses efficiently.

Stainless steel requires more power to maintain clean, oxide-free edges.

Aluminum and copper are reflective and conduct heat rapidly, demanding more laser energy and advanced reflection-protection systems.

Galvanized steel can be cut effectively, but requires fine-tuned parameters to prevent coating burn-off.

For a general-purpose sheet-metal workshop, a mid-range laser provides the best compatibility across these material variations.

Why 3000W Is the Most Versatile Power Choice for Sheet Metal Fabricators

Among all available power tiers, the 3000W fiber laser cutting machine has emerged as the industry’s most balanced solution. It offers excellent cutting capability for the majority of commercial sheet-metal applications without the steep cost associated with 6kW–12kW industrial-grade systems.

A typical 3000W machine can cut:

Carbon steel: up to 10–14mm

Stainless steel: up to 6–8mm

Aluminum: up to 5–6mm

Brass / copper: moderate thickness with stable anti-reflection technology

More importantly, the 3000W level supports extremely high cutting speeds in the 1mm–6mm thickness range—where most fabricated components are produced.

Manufacturers of kitchen equipment, air ducts, automotive brackets, machinery parts, electrical cabinets, elevator panels, and furniture frames often find that 3000W provides everything they need for continuous production.

Cost vs. Capability: The “Sweet Spot” of Productivity

The significance of 3000W lies not just in cutting capability but in overall cost efficiency:

Machines are far less expensive than high-power models.

Electrical consumption remains moderate.

Maintenance and consumables stay affordable.

Assist-gas usage is optimized due to lower piercing times.

Operator training and parameter optimization are simpler.

This makes 3000W an excellent upgrade for shops transitioning away from CO₂ lasers or traditional mechanical cutting technologies.

How Cutting Speed and Edge Quality Affect Real Production Output

Many new buyers focus on laser power alone, but actual productivity is determined by the relationship between cutting speed, edge quality, and machine stability. A fiber laser with well-tuned motion control can outperform a higher-power machine with poor mechanical accuracy or outdated CNC software.

The Real Impact of Cutting Speed

While high wattage boosts cutting speed, other factors matter:

Acceleration and deceleration of the cutting head

Gantry weight and rigidity

Cut-path optimization

Assist-gas pressure and purity

Beam quality from the laser source

Lightweight, high-precision motors and drives

For thin and medium sheet metal, 3000W machines routinely operate at speeds that allow shops to double or triple productivity compared to CO₂ systems.

Edge Quality: A Make-or-Break Factor

In many industries, the cut edge determines whether parts can go straight to bending, welding, or coating. Poor edge quality means extra sanding, grinding, or rework, which destroys production efficiency.

Fiber lasers excel thanks to:

Smaller heat-affected zones

Narrow kerf widths

Smooth, consistent edges

Reduced micro-burr formation

Clean cut surfaces when using nitrogen assist

Especially in stainless-steel products such as kitchenware, elevator panels, or decorative screens, fiber lasers offer a finish that eliminates the need for additional polishing.

Comparing Performance Across Different Sheet-Metal Types

Fiber laser cutting machines are renowned for versatility. However, each material behaves differently under laser energy.

Carbon Steel

The easiest material to process. Fiber lasers deliver exceptional speed and clean edges, especially with oxygen for thicker sheets and nitrogen for burr-free thin cuts.

Stainless Steel

Benefits greatly from nitrogen cutting, producing non-oxidized, mirror-like edges ideal for food equipment, medical devices, and architectural components.

Aluminum & Alloys

More challenging due to reflectivity, but modern fiber lasers with back-reflection protection and high-pressure nitrogen can produce excellent results.

Galvanized Steel

Requires balanced parameters to avoid burning off the coating, but fiber lasers cut it effectively for HVAC ducts, cabinets, and enclosures.

Evaluating the Total Cost and Long-Term ROI of a Fiber Laser

While purchase price is always a major factor, the long-term return on investment often matters more. Fiber lasers are known for low operating costs and high machine uptime.

Key contributors to ROI include:

Energy savings: Fiber lasers use up to 50% less electricity than CO₂ systems.

Maintenance reduction: No mirrors, sealed optics, longer laser-source life.

Material savings: Better nesting, narrower kerf, fewer rejected parts.

Automation compatibility: Loaders, unloaders, pallet changers, and sorting systems extend productivity.

Labor efficiency: Operators can manage more machines with less manual intervention.

Most shops recover their investment in 12–36 months depending on production volume.

Practical Buyer Tips for Choosing the Right Machine

Before purchasing a fiber laser cutting machine, consider the following:

Assess Your Main Material Thickness

Choose a power range that matches your primary workload—not your rarest jobs.

Select the Appropriate Cutting Bed Size

3015 (3m × 1.5m) is the most common, while larger beds increase productivity for oversized parts.

Evaluate CNC Software and Motion Control

Smooth, stable motion translates directly into cleaner edges and faster production cycles.

Look for Reliable Laser Sources and Components

Brands like IPG and Raycus are known for stable beam quality and long service life.

Consider After-Sales Support

A strong technical team, quick-response remote service, and accessible spare parts are essential for minimizing downtime.

Final Thoughts

Choosing the best fiber laser cutting machine for 3mm–20mm sheet metal is ultimately about balancing performance, cost, and long-term flexibility. For most metal fabrication shops, a 3000W fiber laser provides outstanding versatility, fast processing, excellent cut quality, and a strong return on investment. By understanding material requirements, evaluating cutting speeds, and selecting reliable machine components, manufacturers can make a confident decision that supports both current operations and future growth.