Driving Productivity in Today’s Sheet Metal Industry

The sheet metal processing industry is experiencing continuous transformation. From rising customization demands to shorter delivery cycles and increasing cost pressures, fabricators must achieve higher efficiency and precision than ever before. Modern customers expect flexible production, flawless quality, and smooth digital workflows — whether producing components for machinery, construction, appliances, vehicles, or custom metal products.

Our advanced portfolio of laser cutting, tube processing, CNC bending, welding, H-beam solutions, and intelligent automation lines empowers sheet metal manufacturers to build smarter and more profitable operations.

Comprehensive Solutions for Every Stage of Sheet Metal Fabrication

Our equipment and technologies cover the full workflow of sheet metal processing, enabling continuous, stable, and highly scalable production.

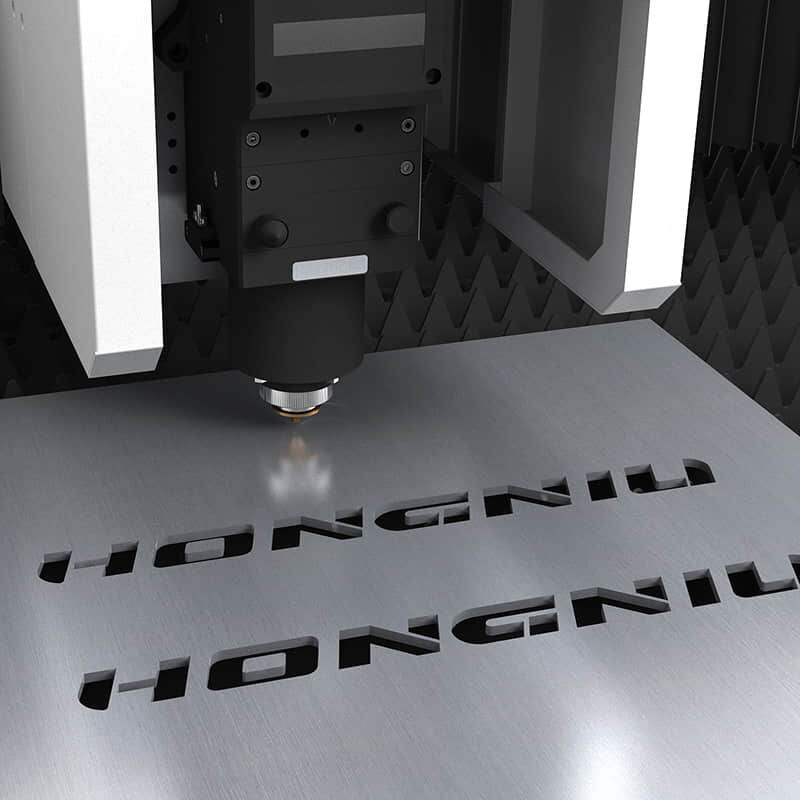

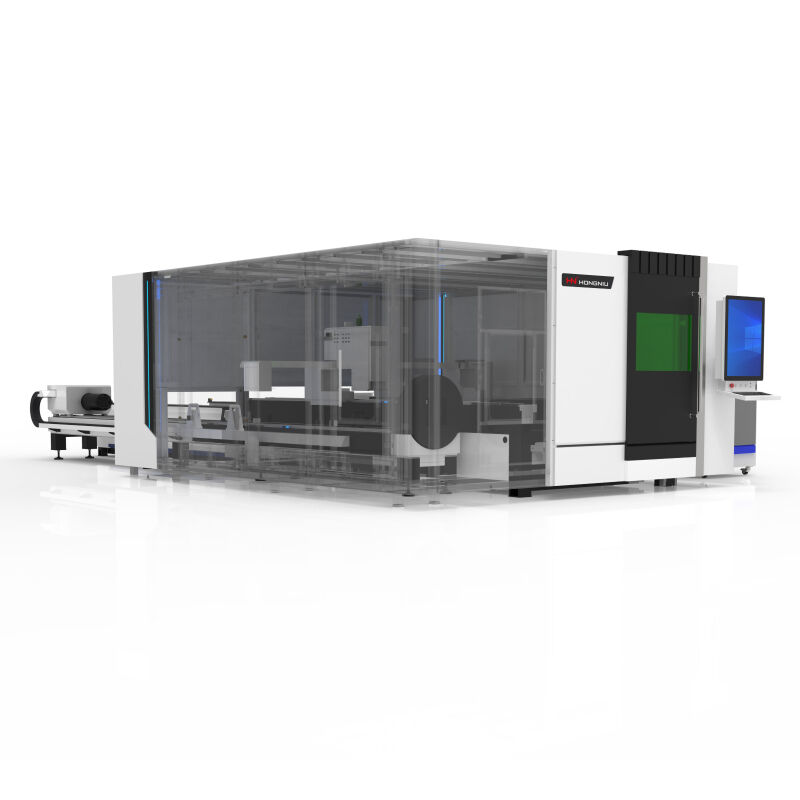

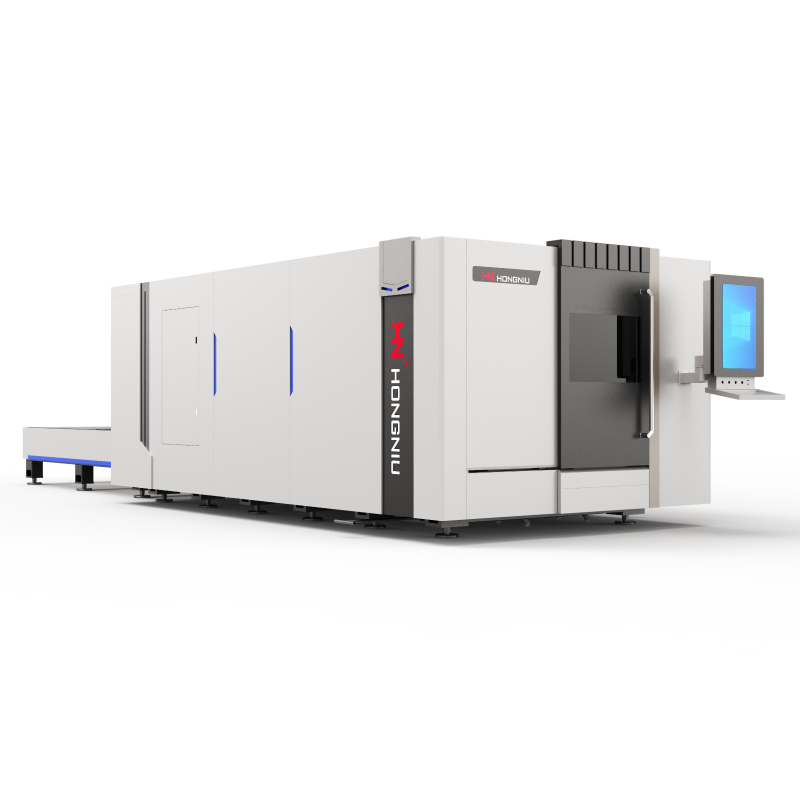

Sheet Metal Laser Cutting Machines

High-speed, ultra-precision cutting for a wide range of flat sheet components. Ideal for carbon steel, stainless steel, aluminum, galvanized steel, and mixed materials.

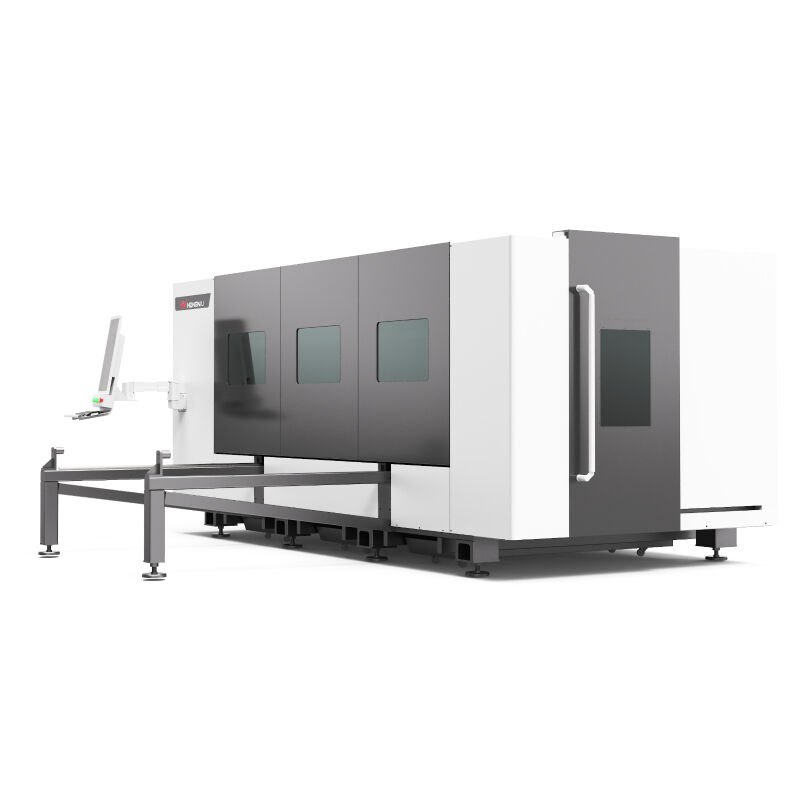

Tube & Tube-Metal Laser Cutting Machines

Perfect for tubular parts, frames, brackets, supports, structural pipes, and customized profile components used across machinery, furniture, vehicles, and construction.

Reliable, consistent bending for complex shapes and precise angles — ensuring accuracy and repeatability in structural parts, enclosures, cabinets, and architectural metals.

Deliver strong, clean weld joints for high-precision assemblies, stainless steel products, machine frames, metal cabinets, and decorative sheet metal.

H-Beam & Heavy-Section Laser Solutions

Engineered for heavy-duty fabrication involving thick plates, large structural components, and building frames.

3D Robotic Laser Systems

A flexible automated solution for trimming, welding, drilling, or cutting 3D structures, complex shapes, curved surfaces, or large-format metal parts.

A fully automated workflow integrating loading, sorting, cutting, bending, welding, and logistics handling — ideal for large-scale factories moving toward Industry 4.0.

Key Applications in Sheet Metal Processing

Our solutions empower manufacturers to produce a broad range of components with exceptional consistency and efficiency.

Machinery & Industrial Equipment

- Machine enclosures and panels

- Chassis and support structures

- Mechanical brackets and functional components

Building & Architectural Metalwork

- Decorative panels, façades, and interior metal designs

- Doors, windows, partitions, and wall systems

- Air ducts, ventilation systems, and structural elements

Electrical Cabinets & Control Systems

- Power distribution boxes

- Industrial cabinets and control panels

- Precision-formed enclosures and frames

Home Appliances & Consumer Products

- Stainless steel kitchen equipment

- Appliance panels and structural parts

- Ventilation, heating, and cooling components

Automotive & Transportation

- Structural brackets and reinforcement parts

- Interior metal components

- Prototyping for low-volume or custom builds

Custom Metal Fabrication

- Artistic metalwork, signage, and custom products

- Furniture structures and design fixtures

- High-mix, small-batch product manufacturing

Benefits of Laser Technology for Sheet Metal Manufacturers

Fast Production, Faster Delivery

Laser systems dramatically reduce cutting time and increase overall productivity, even for complex geometries.

High Precision & Excellent Edge Quality

Achieve clean, smooth edges with minimal post-processing — ideal for welded assemblies and high-value products.

Ultimate Flexibility in Design & Production

Easily adapt to new product variations, prototypes, and custom orders without additional tooling.

Reduced Waste, Lower Costs

Optimized nesting and narrow kerf width improve material utilization and reduce overall costs.

Stable Quality, Less Manual Labor

Consistent laser performance ensures reliable quality while reducing labor dependency.

Automation Ready for Industry 4.0

Intelligent production lines support digital management, real-time monitoring, and highly efficient automated workflows.

Building Smarter Sheet Metal Factories

Modern sheet metal manufacturers need advanced technology to stay competitive — faster cutting, reliable bending, precise welding, and smooth automation. Our integrated laser and automation solutions offer an end-to-end pathway to higher efficiency, better quality, and sustainable growth.

By combining precision, flexibility, and intelligent production, we help sheet metal companies transform their workshops into next-generation smart factories.

Empower your sheet metal production with advanced laser technology — and unlock new levels of speed, quality, and profitability.