Leading the Future of Automotive Production

The automotive industry is undergoing a profound transformation. Lightweight structures, new energy vehicles, increasingly complex geometries, and shorter product life cycles are redefining manufacturing requirements. Automakers and suppliers must deliver exceptional precision, stable quality, and scalable production — all while maintaining flexibility for rapid design changes.

Our advanced laser cutting, tube processing, bending, welding, and intelligent automated solutions empower automotive manufacturers to meet these challenges with speed, accuracy, and full-process integration.

A Complete Portfolio Designed for Automotive Excellence

Our technologies cover every key stage of metal processing in automotive manufacturing, helping you achieve efficient and reliable production of both traditional and next-generation vehicles.

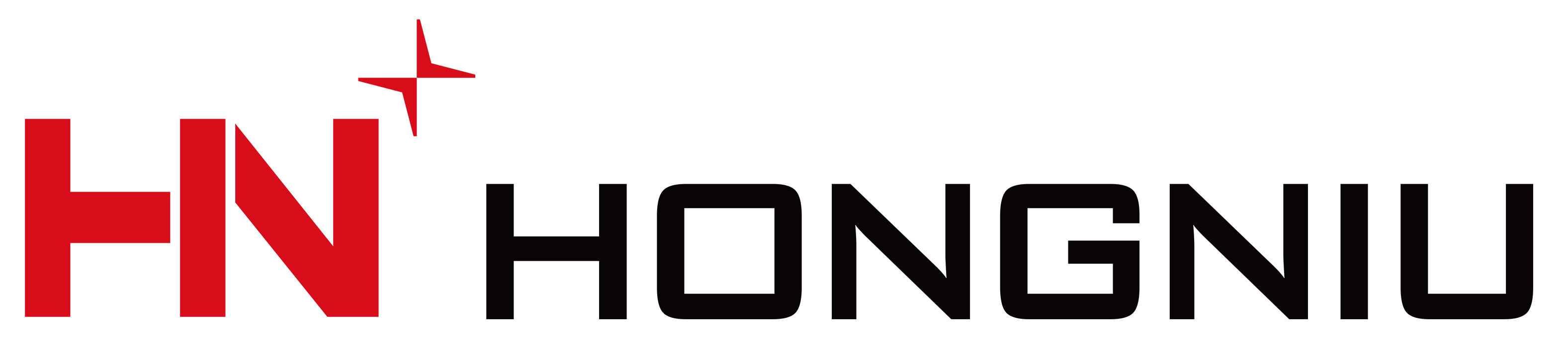

Sheet Metal Laser Cutting Machines

High-speed, high-precision cutting for body panels, structural components, brackets, and interior/exterior metal parts. Ideal for thin-sheet and mixed-metal processing with minimal heat distortion.

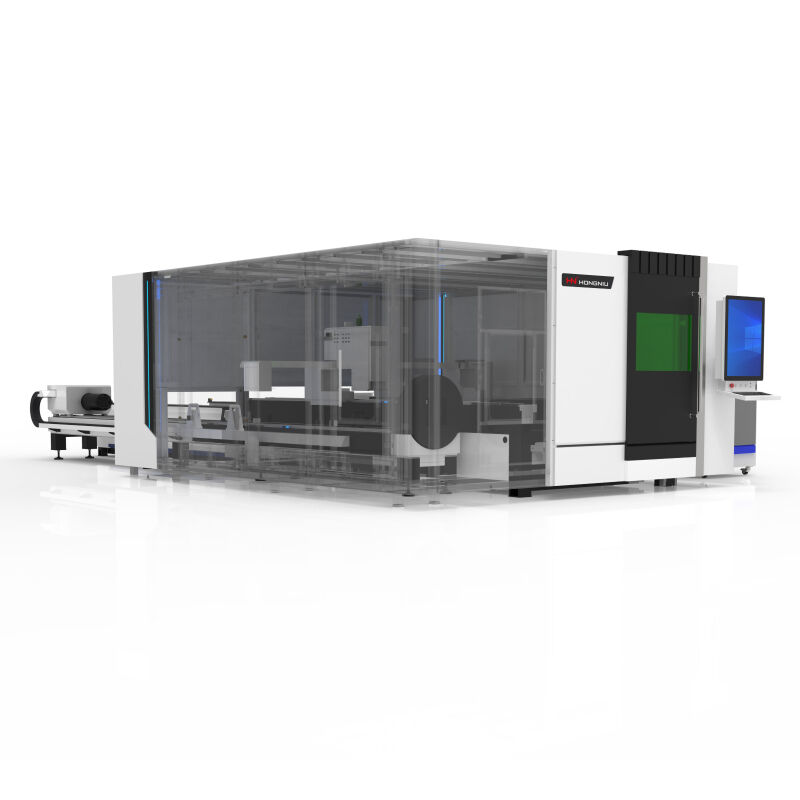

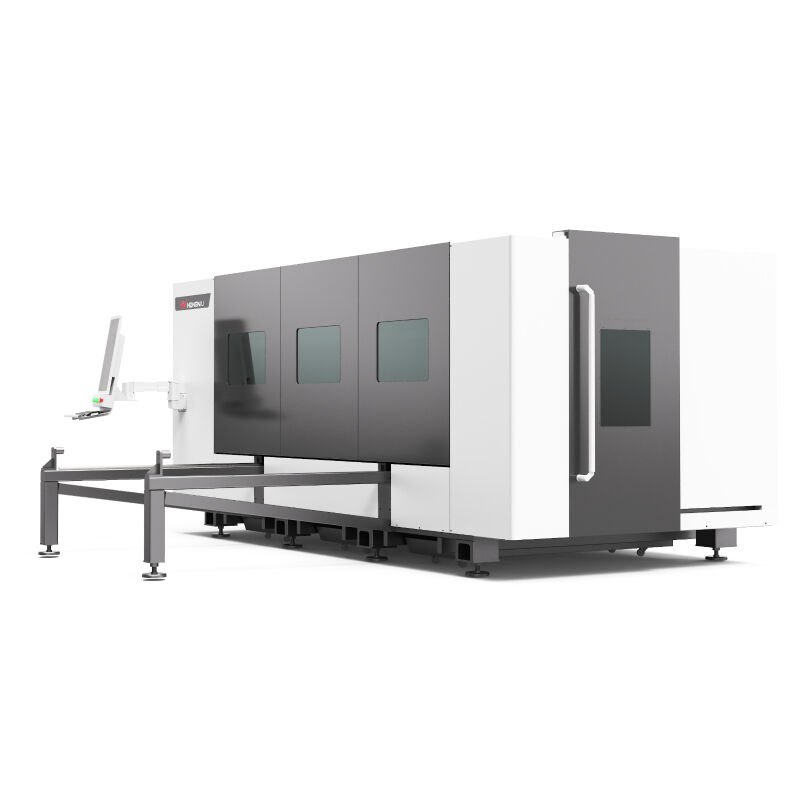

Tube & Tube-Metal Laser Cutting Machines

Essential for chassis components, sub-frames, suspension parts, exhaust systems, roll cages, battery carriers, and structural tubing used in both conventional and electric vehicles.

Form sheet and tube components into precise shapes for reinforcements, brackets, frames, and underbody supports. Ensures consistent bending angles and repeatability.

Deliver strong, clean weld joints for battery structures, body-in-white (BIW) parts, and high-strength steel components. Laser cleaning improves pre-weld surface quality and post-weld finishing.

Flexible, programmable automation for trimming, cutting, welding, or drilling of 3D parts. Perfect for curved surfaces, complex contours, and multi-variant production.

Intelligent Laser Cutting Production Lines

A fully automated system integrating loading, cutting, sorting, bending, welding, and logistics — enabling high-throughput, low-labor, Industry 4.0-ready automotive manufacturing.

Key Automotive Applications

Our solutions support a wide range of automotive metal components, ensuring accuracy, repeatability, and production stability.

Body-in-White (BIW) Components

Laser cutting ensures precise manufacturing of: - Floor panels - Door frames - Roof supports - Crash-relevant structures - Reinforcement panels

High accuracy minimizes assembly gaps and reduces the need for rework.

Chassis and Structural Frames

Tube laser cutting enables complex geometries for: - Sub-frames and cross-members - Roll cages - EV battery support frames - Structural tubes and profiles

Clean, smooth edges ensure strong weldability and structural integrity.

Exhaust, Drivetrain & Underbody Components

Stable, clean cutting ideal for: - Exhaust pipes and muffler parts - Mounting brackets - Heat shields - Underbody protection parts

Laser processes maintain consistent performance across large-volume production.

Interior & Exterior Metal Trim

For decorative components and functional brackets: - Dashboard metal inserts - Seat structures - Sensor mounts - Custom trim designs

Laser cutting allows high precision in small geometries and complex patterns.

Prototyping & Low-Volume Production

No molds, no tooling — just CAD files. Laser systems enable rapid design changes for: - Concept cars - Custom modifications - Special editions - Low-volume EV startups

Ideal for fast development cycles and flexible model variations.

Benefits for Automotive Manufacturers

High Precision for Perfect Fitment

Laser cutting delivers ultra-tight tolerances to ensure that BIW and chassis components align precisely during assembly.

Higher Efficiency and Shorter Lead Times

Fast cutting speeds, automatic material handling, and minimal setup time accelerate production cycles.

Flexibility for Rapid Model Updates

No need for new dies or molds. Design changes can be implemented digitally within minutes.

Reduced Material Waste

Optimized nesting, narrow kerf width, and clean cuts maximize material utilization.

Low Heat Distortion & Excellent Edge Quality

Ensures better welding performance and reduces secondary processes like sanding or grinding.

Automation for Scalable Production

Robots, sorting systems, and smart production lines support mass production with minimal manual labor.

Ideal for Lightweight & EV Structures

Laser technology excels in processing thin sheets, aluminum alloys, and complex EV battery structures.

Driving Smarter, Faster, and Greener Automotive Manufacturing

With our integrated laser and automation solutions, automotive manufacturers can build more efficient production systems that support modern vehicle design — from lightweight body structures to EV battery modules and intelligent chassis designs.

By combining precision, speed, flexibility, and digital connectivity, we help automotive factories transition toward intelligent, highly efficient, and future-ready manufacturing.

Empower your automotive production with smarter laser technology — and accelerate your path toward next-generation mobility.